In the world of aggregate production, mining, and construction, the efficiency of a crushing operation hinges on the performance of its primary crusher. Among the most popular and reliable models for medium to large-scale operations is the PE750x1060 jaw crusher. This robust machine is engineered to handle hard and abrasive materials with high capacity and reliability, forming the critical first step in the size reduction process.

This article provides a comprehensive overview of the PE750x1060, detailing its key specifications, working principle, and why it remains a top choice for project managers and plant operators worldwide.

Jaw Crusher PE750X1060 Key Specifications and Features

Technical Specifications:

• Feed Opening: 750mm x 1060mm (approx. 30" x 42")

• Max Feed Size: ≤630mm (approx. 25 inches)

• Discharge Opening Range: 80-140mm (3" - 5.5")

• Capacity: 110-380 tons per hour (TPH)*

• Eccentric Shaft Speed: 250 rpm

• Motor Power: 90-110 kW (typically 110kW or 150 HP)

* Note: Capacity varies based on material properties, feed gradation, and discharge setting.

Design Advantages:

• Robust Construction: Built with high-quality steel plates and castings, the crusher frame is designed to withstand the immense stress of crushing hard rock.

• Deep Crushing Chamber: The deep chamber allows for a large feed size and promotes a high reduction ratio, meaning it can break large rocks down to a manageable size in a single pass.

• Reliable Eccentric Shaft: A large-diameter forged eccentric shaft mounted on anti-friction bearings ensures smooth operation and long service life under heavy loads.

• Durable Jaw Plates: The fixed and movable jaw plates are made from high manganese steel or other wear-resistant alloys, designed to be replaced when worn out.

• Adjustable Discharge Setting: A hydraulic or mechanical toggle adjustment system allows operators to easily change the crusher's closed-side setting (CSS) to produce the desired product size, enhancing flexibility for different project requirements.

• Simple and Safe Operation: Designed with safety in mind, its operation is straightforward, and maintenance points are easily accessible.

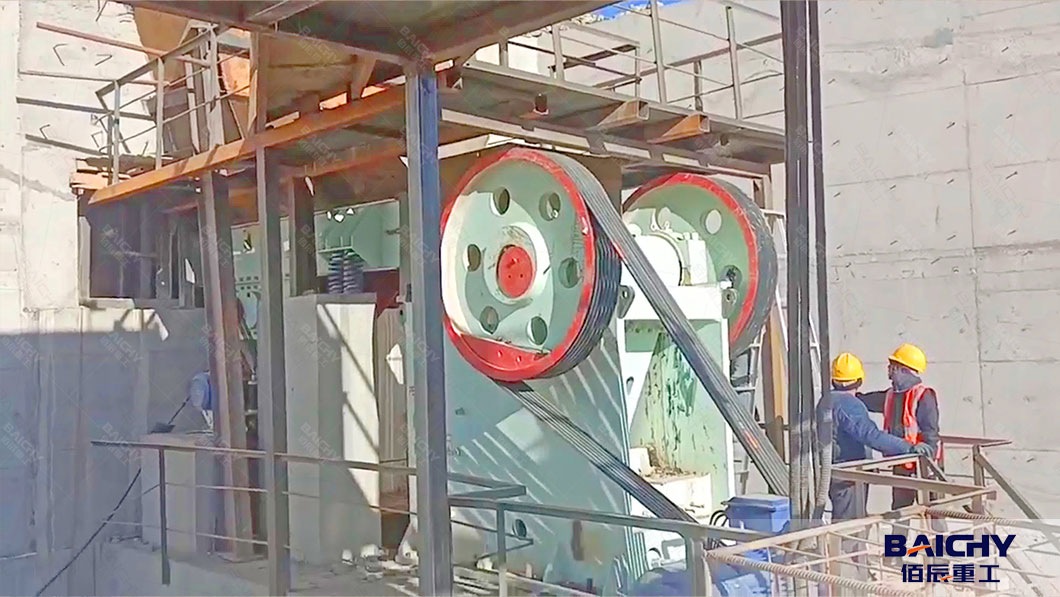

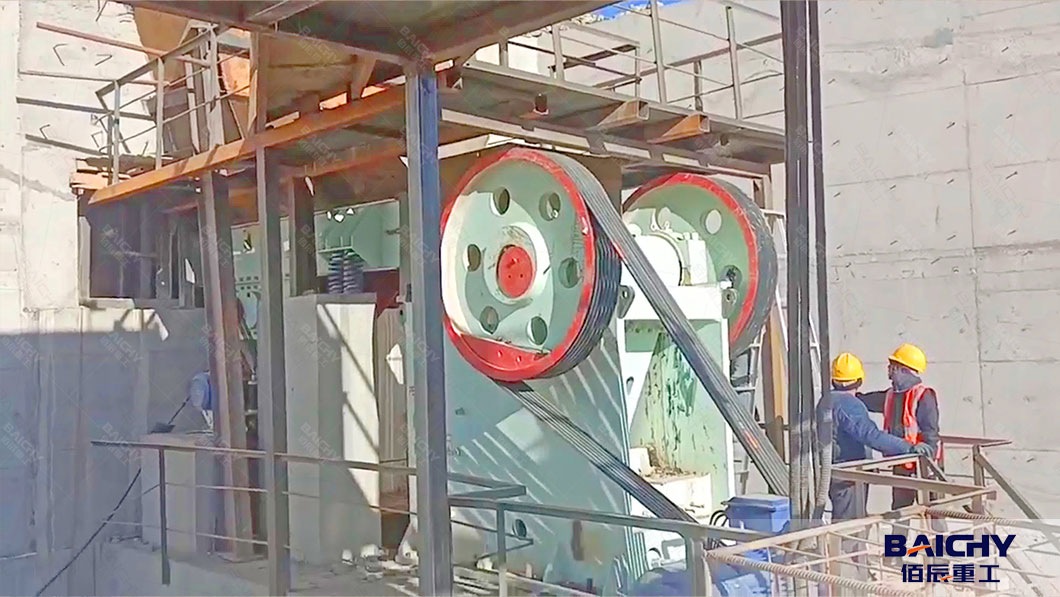

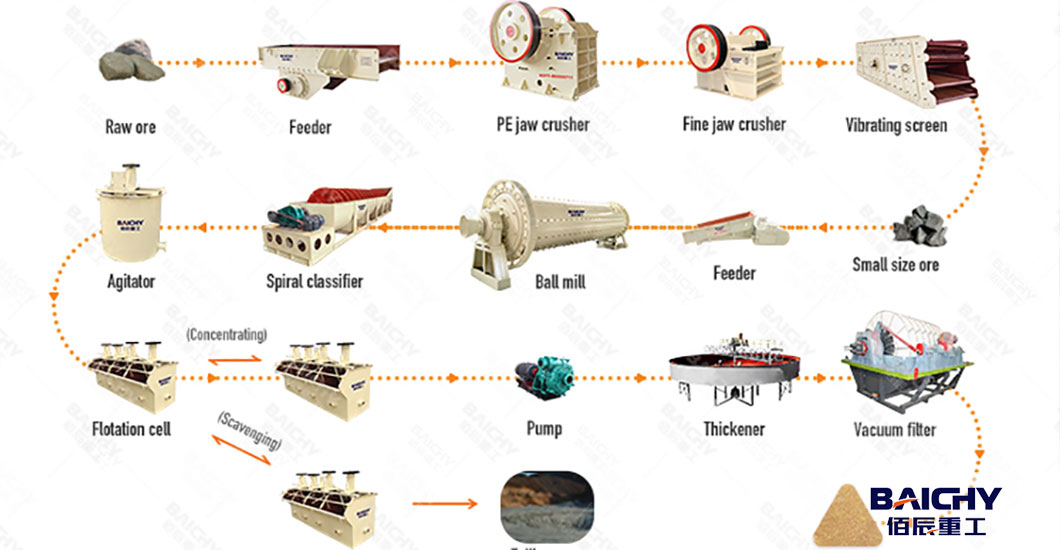

How Does the PE750x1060 Jaw Crusher Work?

The PE750x1060 operates on the principle of compressive force, often referred to as a "chamber and press" action.

1. Loading: Large rocks (feed) are deposited into the top of the crusher's chamber from a dump truck or feeder.

2. Crushing Cycle: The motor drives the eccentric shaft, causing the movable jaw to move in an elliptical motion. As it moves towards the fixed jaw, the rock is compressed and crushed.

3. Discharge: As the movable jaw moves away from the fixed jaw, the crushed material gravitates down the chamber. Smaller material passes through the bottom discharge opening (set by the CSS), while larger pieces are repeatedly crushed until they are small enough to exit.

This cyclical process continues, providing a consistent flow of crushed aggregate.

Primary Applications

The versatility of the PE750x1060 makes it suitable for a wide range of industries:

• Mining: Primary crushing of ores like gold, copper, and iron.

• Quarrying: Producing aggregate ( crushed stone, gravel) for construction and road building.

• Construction and Demolition: Recycling concrete and rubble into reusable base material.

• Industrial Applications: Processing various industrial minerals.

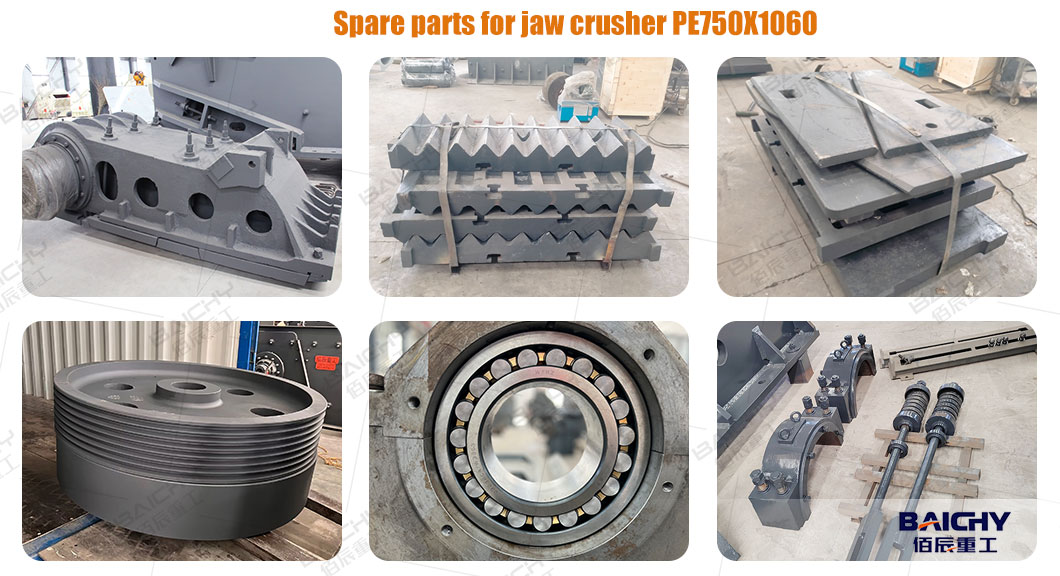

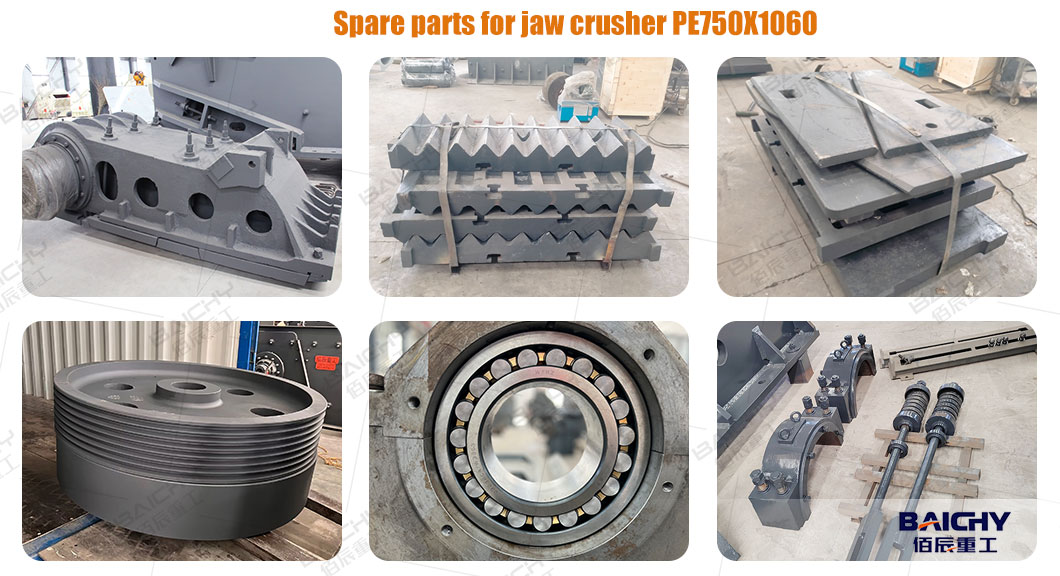

3.Jaw Crusher Spare parts

Spare parts of jaw crusher PE750X1060 is movable jaw plate, fixed jaw plate, side plate, toggle plate, bearings, spring etc. The main jaw plates are generally made of high manganese steel with high manganese steel has highly wear resistance. The service life of wearing parts varies depending on the hardness of the crushed stone. In general, crushing limestone can be used for about 2 years; crushing granite can be used for about 1 year.

We guarantees all our equipment for one yea(except for wearing parts) and maintained for life. And timely supply of spare parts with high quality and good price.

Why Choose the PE750x1060?

Selecting the PE750x1060 offers several strategic benefits:

• High Capacity: Its processing capacity 300 TPH+ potential makes it ideal for meeting the production demands of medium to large quarries and mines crushing plant

• Proven Design: The PE series design is a industry standard known for its simplicity and reliability, minimizing unexpected downtime.

• Cost-Effectiveness: It offers an excellent balance between initial investment, operational costs, and production output, providing a strong return on investment.

• Wide Availability: Being a common model, replacement parts and jaw plates are readily available from multiple suppliers, reducing lead times for maintenance.

People also frequently Ased For-FAQ

1.How much is jaw crusher PE750X1060?

There are many factors to affect jaw crusher pe750x1060 price, such as steel cost, manufacturing cost, manufacturer brand etc. You can click to contact us to get the latest jaw crusher price list.

2.What is the price of 300 TPH jaw crusher?

Jaw crusher PE760X1060 is suitable model to reach crushing capacity 110-380tph. Baichy supply high quality and good price jaw crushers. Welcome to contact us to get discount price.

3.Jaw crusher pe750x1060 manual

PE series jaw crusher is typically used as primary crusher or the first step in the process of reducing rock. They typically crush using compression. Baichy provides professional sale service, including solution design, drawing, manual, installation and training etc.

2026-02-07

2026-02-07

86-15093113821

86-15093113821

86-15093113821

86-15093113821