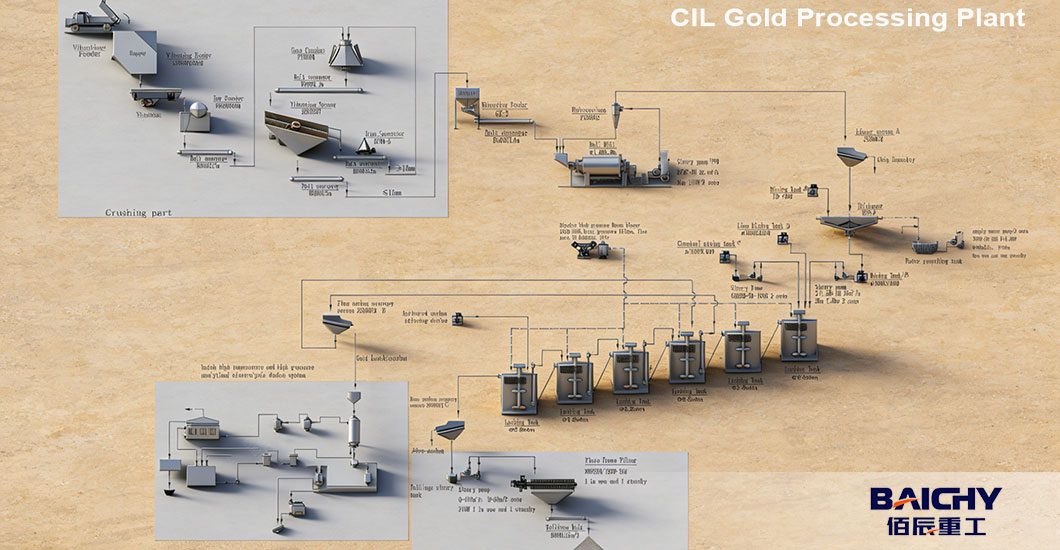

For fine-grained in-situ gold deposits with small particles (typically less than 10 μm) and uniformly embedded in gangue minerals (such as quartz and feldspar), the CIL gold processing plant (Carbon In Leach, carbon-based leaching process) is the most mainstream gold recovery technology in industry. Its core advantage lies in the simultaneous execution of gold cyanide leaching and activated carbon adsorption, without the need for separate leaching tanks and adsorption tanks. The process is compact and has a high gold recovery rate, perfectly addressing the challenges of difficult gold recovery and easy loss of fine-grained gold. It is the preferred solution for large-scale gold recovery from fine-grained in-situ gold deposits.

I. CIL Gold Processing Plant Principle

The core of the CIL process is "leaching and adsorption simultaneously". These two steps are carried out in parallel to recover gold:

1. Cyanide leaching: The cyanide solution (such as sodium cyanide) reacts with the fine-grained gold deposit, dissolving the solid gold into "gold cyanide complexes" (liquid gold dissolved in the ore slurry);

2. Activated carbon adsorption: While leaching is occurring, granular activated carbon is added to the ore slurry. The gold cyanide complexes will quickly adsorb onto the surface of the activated carbon, preventing fine-grained gold from being lost in the ore slurry;

3. Finally, through distillation and electrolysis, pure gold is recovered from the activated carbon.

In simple terms: The CIL process is to make the gold "dissolve into a liquid state" and immediately be "captured" by the activated carbon. There is no chance for the gold to "escape".

II. Key Process Steps

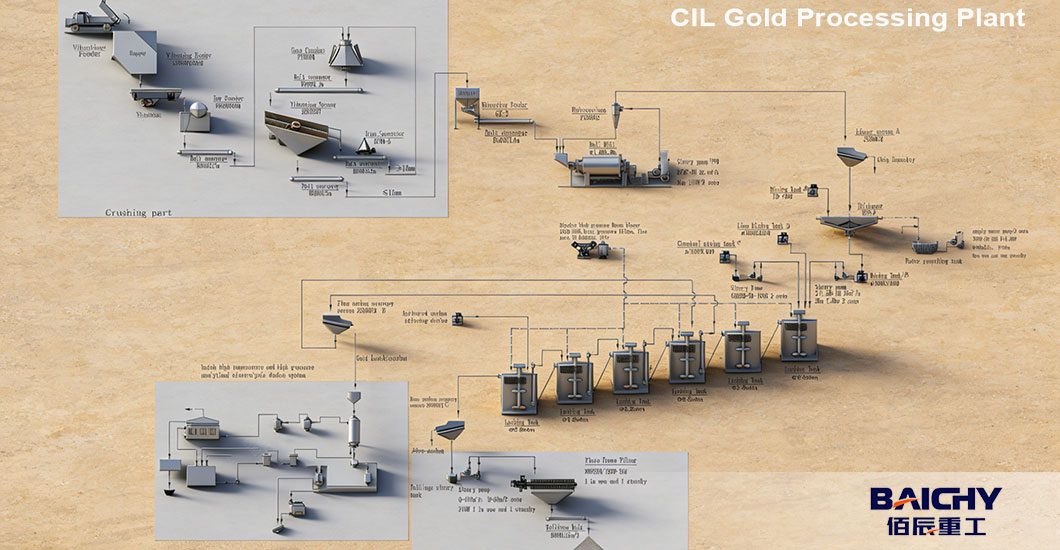

1. Pre-treatment: Ore slurry preparation

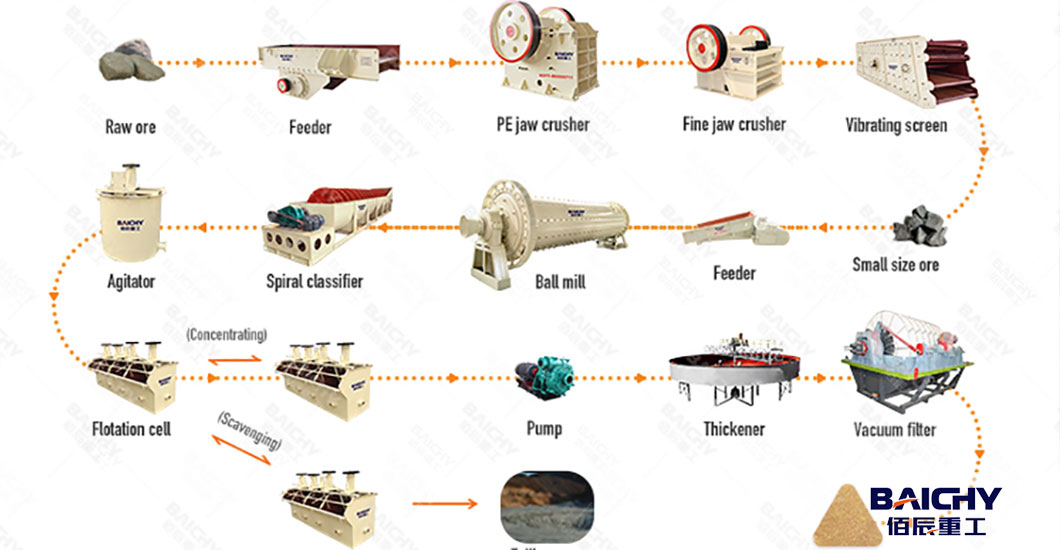

• The ore needs to be ground to below 75 μm (for fine-grained in-situ gold deposits, it needs to be below 53 μm) to ensure that the fine-grained gold is fully exposed (if it is encapsulated in sulfide minerals, it needs to be pre-treated by flotation);

• Adjust the pH of the ore slurry to 10-11 (using lime to adjust), inhibiting the hydrolysis of cyanide and reducing the interference of harmful impurities (such as copper and iron) on the leaching;

• The concentration of the ore slurry is controlled at 40%-50%, ensuring that the reagents and gold particles are fully in contact.

2. Core Step: "Leaching + Adsorption" in the CIL tank

• The ore slurry is sent to a series of CIL tanks (usually 3-6), with sodium cyanide solution (concentration 0.03%-0.05%) and activated carbon (particle size 1.0-1.6 mm) added to the first tank;

• The ore slurry flows slowly in the CIL tank (staying time 24-48 hours), with impeller stirring to ensure the cyanide, activated carbon, and ore slurry are fully mixed:

◦ The cyanide continuously dissolves the fine-grained gold, forming gold cyanide complexes;

◦ The activated carbon particles act like "magnets", constantly adsorbing the gold cyanide complexes in the ore slurry, preventing their loss in the subsequent process;

◦ The activated carbon passes through each CIL tank successively, and the gold adsorption gradually saturates, finally being discharged from the last tank (rich gold carbon); the tailings (ore slurry without gold) are discharged from the bottom of the last tank.

3. Subsequent Processing: Gold Recovery from Rich Gold Carbon (Three Steps to Pure Gold)

• Distillation: Send the rich gold carbon to the distillation column, treated with high-temperature and high-pressure alkaline solution (NaOH) and sodium cyanide solution to allow the gold cyanide complexes to "detach" from the activated carbon, obtaining a high-concentration gold-containing solution;

• Electrolysis: Pass the gold-containing solution through the electrolytic cell, through the electrolytic action, allowing gold to deposit on the cathode plate, forming gold sludge (gold content 50%-70%);

• Smelting: The gold sludge is acid-washed to remove impurities and sent to the medium-frequency furnace for smelting, ultimately obtaining 99.99% pure gold ingots.

III. CIL Gold Process Advantages

1. High gold recovery rate: For fine-grained gold (<10 μm), the recovery rate can reach 90%-95%, far exceeding the traditional cyanide leaching (only 80%-85%), avoiding the loss of fine-grained gold in the ore slurry;

2. Compact process: Integration of leaching and adsorption eliminates the need for a separate adsorption tank, reducing equipment investment by 20%-30% and minimizing floor space (suitable for small and medium-sized mines);

3. Strong anti-interference ability: Activated carbon can directly adsorb gold cyanide complexes, reducing the impact of mud and impurities in the ore pulp on gold recovery, and having a high tolerance for fluctuations in ore grade;

4. Simple operation: High automation level, only requiring control of pulp flow rate, reagent concentration and activated carbon dosage. Workers can easily operate and maintenance costs are low.

Four key points to note:

1. Grinding must meet standards: Fine-grained leachable gold ores need to be ground to below 53μm; otherwise, the gold particles will not be exposed, and the leaching rate will significantly decrease;

2. Precise cyanide dosage: Excessive cyanide increases costs and pollutes the environment, while too little results in insufficient gold dissolution. It is recommended to control the dosage at 0.03%-0.05%;

3. Selecting suitable activated carbon: Preferentially use coconut shell activated carbon (large adsorption capacity, wear-resistant), with a particle size of 1.0-1.6mm. Avoid excessive loss and low adsorption efficiency for larger particles;

4. Strictly control the pH value of the pulp: It must be maintained at 10-11; otherwise, cyanide is prone to decompose and lose effectiveness, and it will corrode equipment;

5. Complete environmental treatment: Cyanide is toxic, and it is necessary to be equipped with a sodium hydroxide cyanide-breaking device (such as alkaline chlorination method). The cyanide content in the treated wastewater must be less than 0.5mg/L before discharge.

Baichy’s mining machinery equipment offers:

● Tailored configurations for different gold ores.

● Rapid deployment and easy operation in sites.

● Low total cost of ownership (TCO) with energy-efficient operation and durable parts.

● Compliance with global environmental and safety standards.

With 20 years of experience in crushing equipment and successful projects across Kenya, Zimbabwe, Chile, Mexico, Fhilippines and beyond, Baichy is a trusted partner for mining operations worldwide. Contact Baichy today to find the perfect gold processing plant solution for your needs.

2026-02-04

2026-02-04

86-15093113821

86-15093113821

86-15093113821

86-15093113821