For gold ores containing associated sulfide minerals such as pyrite, pyrrhotite, chalcopyrite, etc., the gold ore flotation process is one of the core beneficiation techniques. Its core logic is straightforward: by taking advantage of the natural hydrophobicity of sulfide minerals, the presence of gold in these sulfide minerals can be attached to air bubbles and float to the surface, achieving separation from gangue minerals such as quartz, and laying the foundation for subsequent gold recovery (such as cyanidation leaching). This process is particularly suitable for ores where gold is embedded in sulfide minerals or where gold is coexisting with sulfide minerals. It is simple to operate and highly adaptable, and is the most widely used technology for separating gold-bearing sulfide ores in industry.

I. Gold Ore Flotation Process Principle

Associated sulfide minerals (such as pyrite) have a naturally "hydrophobic" surface (similar to a lotus leaf not absorbing water), while gangue minerals (such as quartz) have a "hydrophilic" surface (similar to a sponge absorbing water). The flotation process achieves separation through three steps:

1. Add reagents to adjust: Add reagents to the ore slurry to enhance the hydrophobicity of sulfide minerals and inhibit the hydrophobicity of gangue minerals, making their "properties opposite";

2. Air agitation: Use a flotation machine to introduce air into the ore slurry to form a large number of tiny bubbles;

3. Adsorption and flotation: Hydrophobic sulfide minerals containing gold will actively attach to the surface of the bubbles and rise to the surface of the ore slurry, forming a "foam product" (i.e., flotation concentrate, with gold grade significantly increased); Hydrophilic gangue minerals will remain at the bottom of the ore slurry and be discharged as tailings.

In simple terms: Flotation is to let the sulfide minerals containing gold "board the air bubble ship" float, while the gangue minerals "sink and leave" at the bottom.

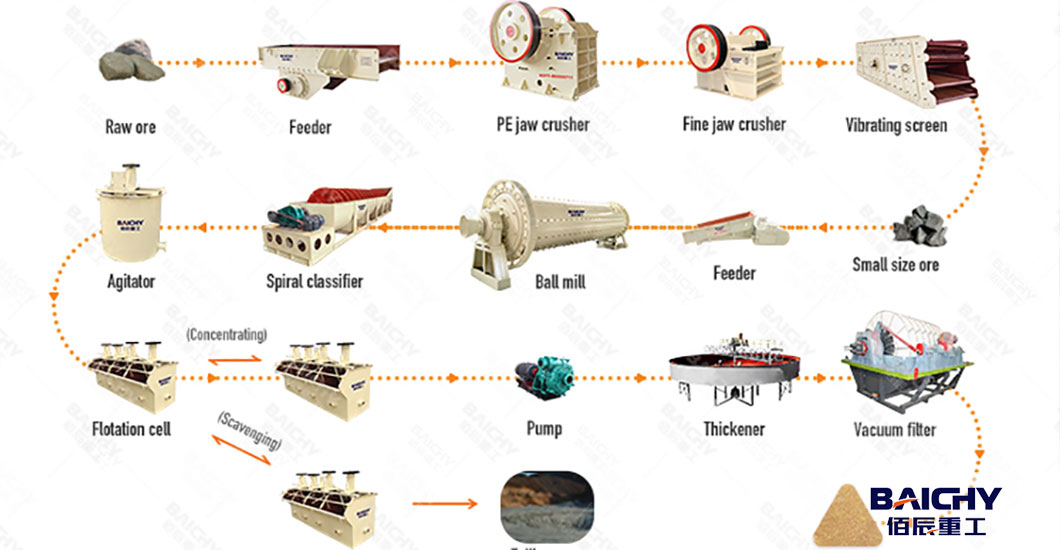

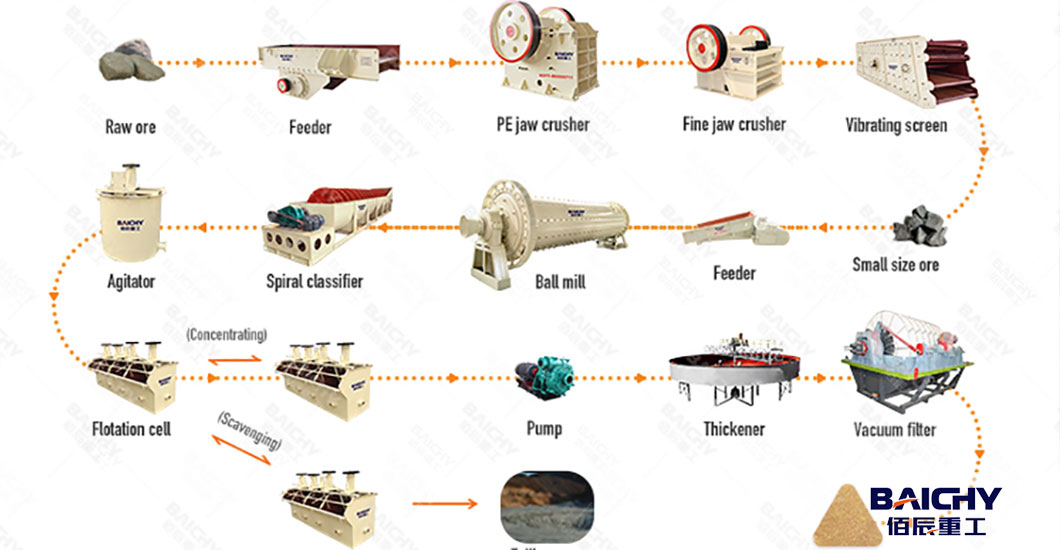

II. Key Process Steps (Simplified Flow)

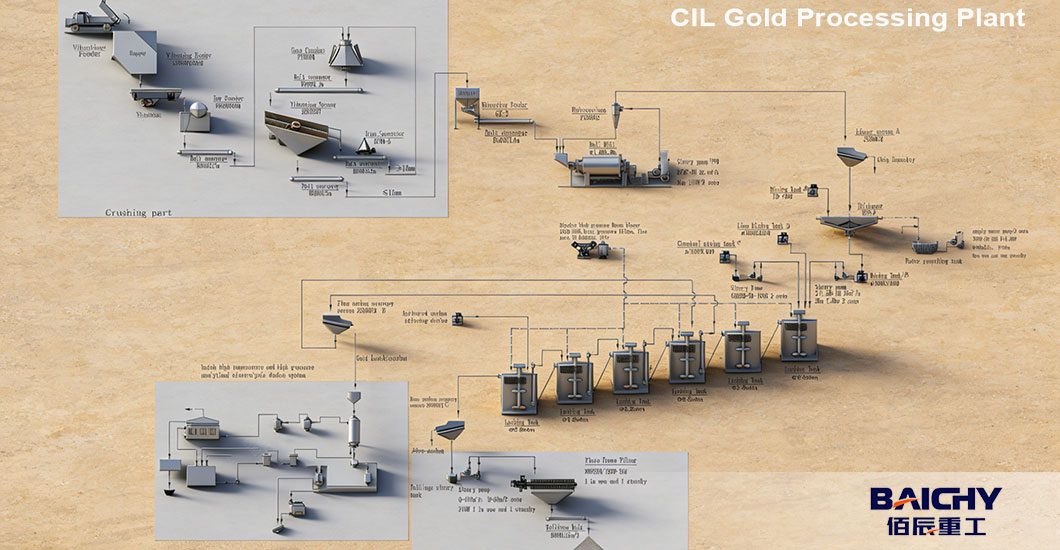

1. Pre-treatment: Ore slurry preparation (preliminary flotation)

• First, using jaw crusher to crush and ball mill to grind the ore to make an ore slurry (the particle size of the ore needs to be below 75 μm to ensure that the sulfide minerals and gold are fully exposed, avoiding "encapsulation loss");

• Adjust the pH of the ore slurry (commonly using lime to adjust to 8-10), creating conditions for subsequent reagent action and inhibiting some harmful impurities.

2. Reagent addition: Core control steps (determining flotation effect)

No complex reagent combinations are needed. The core reagents are only 3 types, with clear functions:

• Collector: Make sulfide minerals more hydrophobic, commonly using yellow drugs (such as butyl yellow) and black drugs, with a small dosage (only a few grams per ton of ore), specifically adsorbing the surface of sulfide minerals;

• Flocculant: Promote the formation and stability of bubbles, commonly using terpineol oil and MIBC, making the bubbles "strong" and uniform, facilitating the carrying of minerals;

• Inhibitor: Inhibit the upward movement of gangue minerals, commonly using lime and water glass, preventing impurities such as quartz from mixing into the concentrate, ensuring the grade of the concentrate;

3. Flotation separation: Core operation (completed in the flotation machine)

• After the ore slurry and reagents are fully mixed, send it to the flotation machine, using the impeller to stir and introduce air to form a bubble-mineral adsorption system;

• Control the air supply, stirring speed and ore slurry flow rate of the flotation machine to allow the foam layer to stabilize and float to the surface, which is the "gold-bearing sulfide mineral concentrate" (the gold grade is usually 5-10 times that of the original ore);

• The tailings (mainly gangue minerals) are discharged from the bottom, with the gold loss rate controlled at 5% or less (adjust according to the characteristics of the ore).

4. Subsequent processing: Gold recovery from concentrate

The flotation concentrate (containing gold + sulfide minerals) needs to be further processed to recover gold, commonly using the "cyanidation leaching + zinc powder replacement" process: The cyanide solution dissolves gold, and then zinc powder precipitates gold from the solution, ultimately obtaining gold sludge (which can be refined into gold ingots).

III. Process Advantages

1. Targeted: Specifically targeting the differences in properties between sulfide minerals and gangue minerals, the gold recovery rate is high (usually 85%-95%), much higher than other processes such as gravity separation; 2. Simple operation: Short process, few equipment required, only core equipment such as flotation machines and dosing devices are needed. Workers can easily get the hang of it and the maintenance cost is low.

3. Wide adaptability: It can handle different types of associated gold-bearing sulfide ores (whether pyrite type, arsenopyrite type or multi-metal sulfide associated gold), and has a high tolerance for fluctuations in ore grade.

4. Cost control: Low dosage of reagents, low energy consumption. During industrial large-scale production, the cost per ton of ore processed is only a few tens of yuan, with outstanding cost performance.

Four. Key precautions (easy to remember)

1. The ore grinding should not be too coarse (it needs to be below 75μm), otherwise the gold and sulfide minerals will not be exposed, and they will be lost along with the tailings.

2. The dosage of reagents should be precise: too much collector will cause gangue to float (decreased concentrate grade), too little will make sulfide minerals not float (reduction of recovery rate).

3. The pH value of the pulp needs to be stable: either too high or too low will affect the reagent effect. It is recommended to control it within 8-10 (adjusting with lime is the most economical method).

4. Avoid mixing oil stains and excessive mud in the pulp: it will contaminate the mineral surface, causing the flotation to "fail", and it is necessary to remove mud and impurities in advance.

Baichy’s mining machinery equipment offers:

● Tailored configurations for different gold ores.

● Rapid deployment and easy operation in sites.

● Low total cost of ownership (TCO) with energy-efficient operation and durable parts.

● Compliance with global environmental and safety standards.

With 20 years of experience in crushing equipment and successful projects across Kenya, Zimbabwe, Chile, Mexico, Fhilippines and beyond, Baichy is a trusted partner for mining operations worldwide. Contact Baichy today to find the perfect gold processing plant solution for your needs.

2026-02-04

2026-02-04

86-15093113821

86-15093113821

86-15093113821

86-15093113821