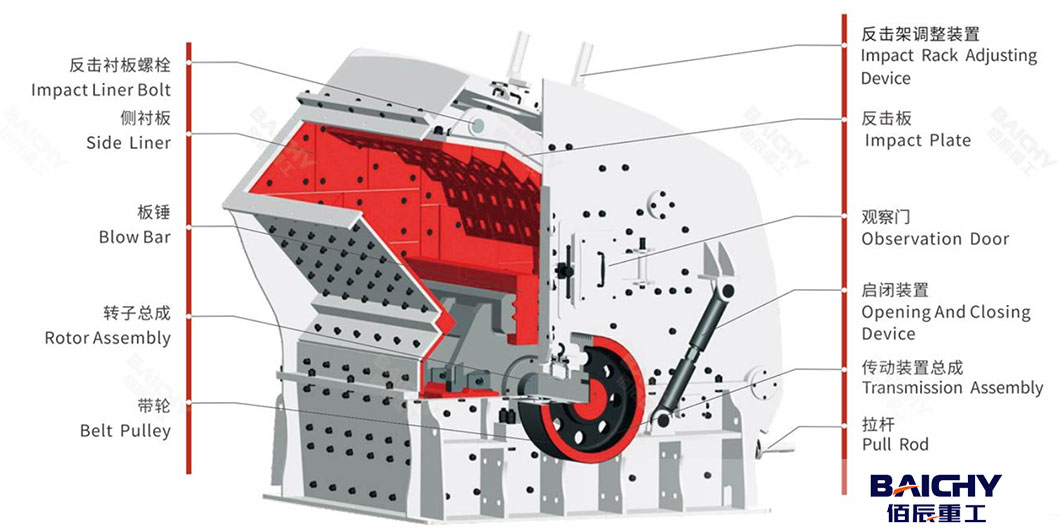

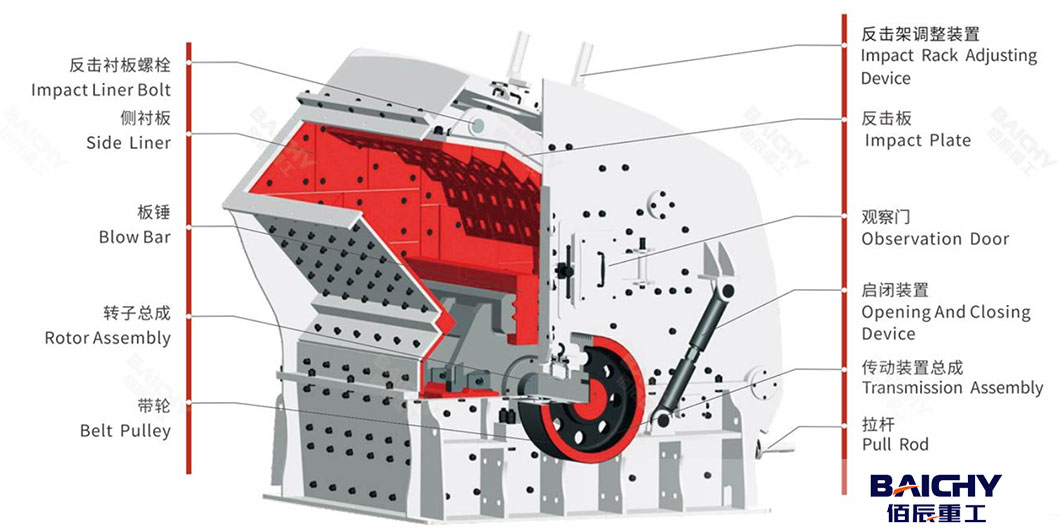

An impact crusher is a dynamic crushing machine that breaks materials using high-speed impact force rather than compression. It operates by feeding raw material into a chamber where a rotating rotor—equipped with wear-resistant blow bars—hurls the material against fixed impact plates (aprons) at high velocity. The material shatters upon collision, then rebounds between the rotor and plates for multi-stage crushing until it reaches the desired size.

There are two main types used in construction:

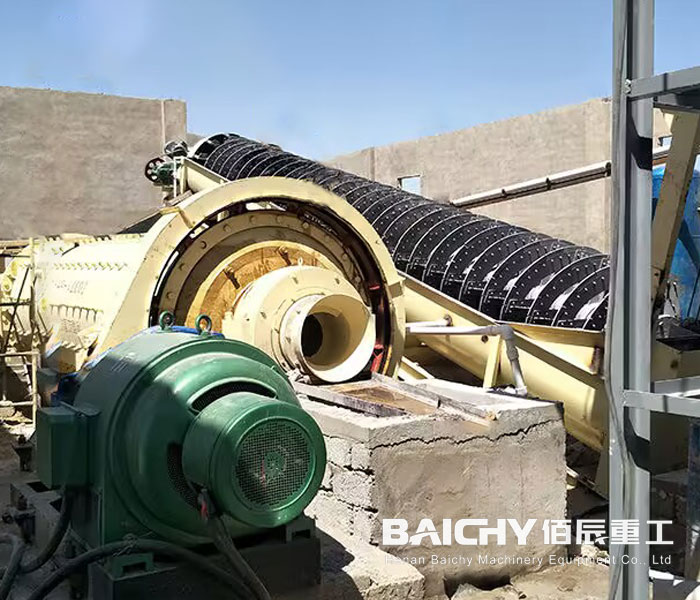

● Horizontal Shaft Impactors (HSI): The most common type, ideal for primary and secondary crushing.

● Vertical Shaft Impactors (VSI): Typically used for the final stage to make sand or shape the aggregate.

Advantages of Using an Impact Crusher

Why do construction managers prefer impact crushers over other types? Here are the five biggest benefits:

1. Superior Particle Shape (Cubical Output)

The most significant advantage is the quality of the final product. Compression crushers (like cones) can sometimes create flat or elongated needles of rock, which are weaker. Impact crushers, by contrast, shatter rock along natural cleavage lines. This produces a uniform, cubical shape that bonds better in concrete and asphalt mixes, meeting strict highway construction standards.

2. High Reduction Ratio

Impact crushers are incredibly efficient. While a jaw crusher might reduce stone at a 3:1 or 4:1 ratio, an impact crusher can achieve reduction ratios of 10:1 or even 20:1. This means you can often do the work of two machines (primary and secondary) with just one impactor, simplifying your plant layout.

3. Unmatched Versatility & Recycling Capability

Impact crushers are the kings of recycling. If you are processing construction and demolition (C&D) waste, an impactor can easily handle concrete reinforced with steel rebar. The blow bars break the concrete away from the metal, and the open discharge design prevents jamming, allowing the steel to be removed by a magnetic separator on the conveyor.

4.Adjustable Output & Easy Operation

Hydraulic or bolt-adjustable impact plates allow quick modification of discharge sizes (10–100mm) to meet project-specific requirements. Modern models also feature smart monitoring systems that track wear parts and performance, reducing downtime for adjustments.

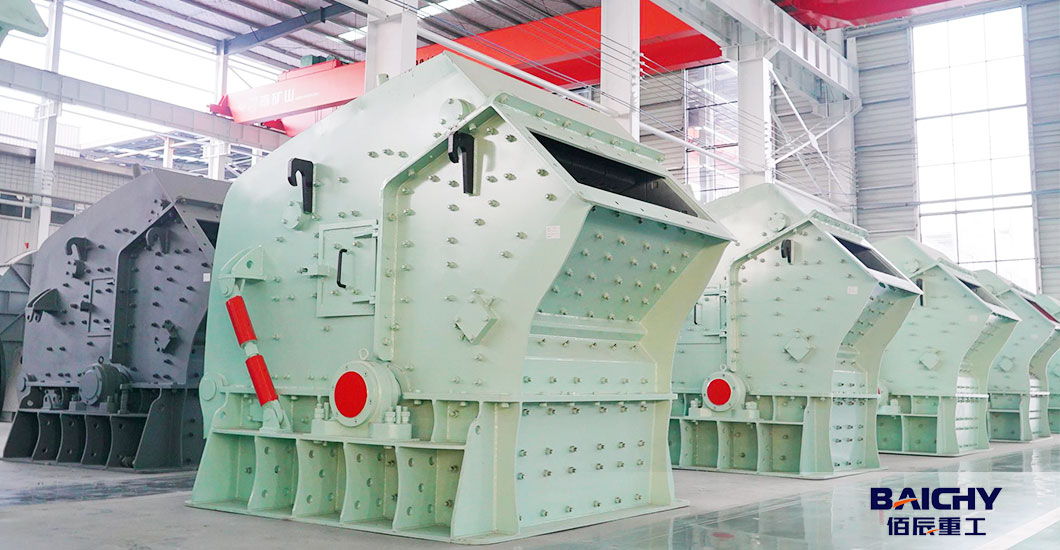

5.Compact Design for Job Site Flexibility

Mobile or skid-mounted impact crushers require minimal site preparation and can be deployed in remote locations—perfect for highway construction, rural infrastructure projects, or urban redevelopment sites with limited space.

Tips for Choosing the Right Impact Crusher

While powerful, impact crushers aren't a "one-size-fits-all" solution. Consider these factors before investing:

● Check Material Hardness: Impactors work best on soft to medium-hard rock (limestone, sandstone, concrete). If you are crushing extremely abrasive material like granite or silica-heavy river stone, the wear costs on the blow bars might be too high. In those cases, a Cone Crusher might be cheaper to run.

● Feed Size vs. Rotor Size: Ensure the inlet opening is large enough for your biggest raw material. A common mistake is buying a machine that fits the tonnage requirement but chokes on large feed rocks.

● Hydraulic Assist: Look for modern models with hydraulic apron adjustments. This allows you to change output size settings in minutes rather than hours, keeping downtime to a minimum.

Success Story: Transforming Waste into Revenue

● Project Background:

A mid-sized construction firm in an urban development zone faced a challenge: they had 50,000 tons of demolition concrete from an old factory site and needed road base for a new logistics park nearby. Hauling the waste away and buying new stone was over budget.

● The Solution:

They installed a mobile Horizontal Shaft Impact Crusher directly on site.

● The Results:

High-Quality Reuse: The impactor successfully separated the concrete from the rebar (which was sold for scrap).

Perfect Spec: The crushed concrete produced a distinct cubical 0-20mm and 20-40mm aggregate that compacted perfectly, passing all density tests for the new road foundation.

Cost Savings: By eliminating transport fees and purchasing costs for new aggregate, the project saved much. The impact crusher effectively turned a waste liability into a valuable asset.

People Also Frequently Asked For - FAQ

1. Why is the aggregate shape from an impact crusher preferred for road construction?

Answer: Impact crushers break rock by striking it rather than squeezing it. This fracture method produces cubical (cube-shaped) particles with sharp edges, which bond much better in asphalt and concrete mixes compared to the flaky or elongated shapes often produced by compression crushers.

2. Can impact crushers handle concrete with steel reinforcement (rebar)?

Answer: Yes, they are excellent for recycling. The powerful blow bars shatter the concrete away from the steel without causing jams. The clean, loose steel can then be easily removed by a magnetic separator on the conveyor, turning waste into reusable construction materials.

3. Is an impact crusher suitable for very hard rock like granite?

Answer: While capable of crushing hard rock, it is generally recommended for soft to medium-hard materials (like limestone or sandstone). Processing highly abrasive or very hard rock will cause the blow bars to wear out very quickly, increasing maintenance costs. For hard rock, a Cone Crusher is often more economical.

2026-01-30

2026-01-30

86-15093113821

86-15093113821

86-15093113821

86-15093113821