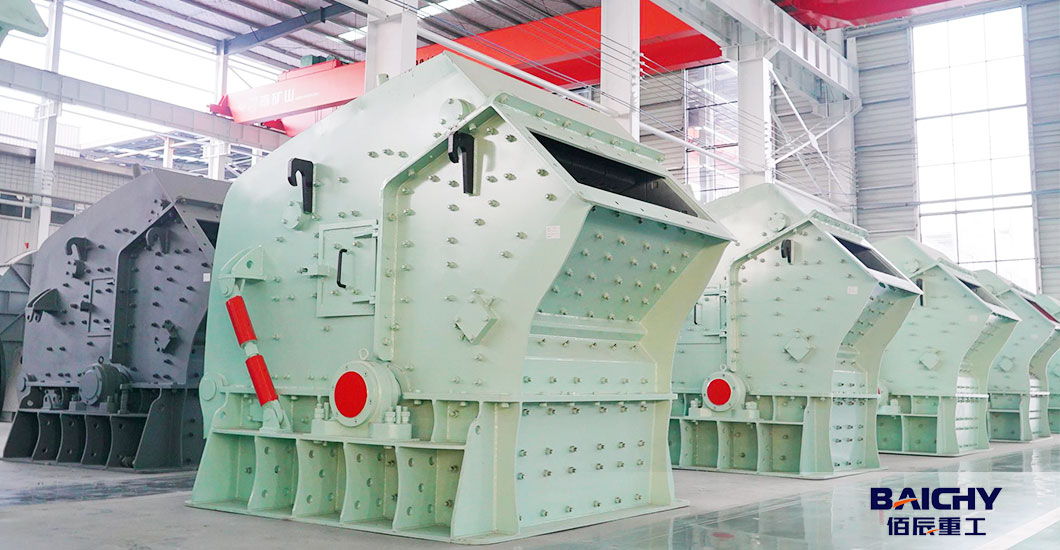

Maximizing the performance and longevity of impact crusher begins with proper operation. This clear, step-by-step guide will help operators ensure efficient crushing, consistent product quality, and reduced downtime.

Step 1: Pre-Operation Inspection & Preparation

Never skip this critical safety and setup stage.

● Visual Inspection: Check the crusher housing, rotor, and exterior for any cracks, damage, or loose parts. Ensure the access doors are securely closed and locked.

● Wear Parts Check: Inspect the blow bars (hammers), impact plates (apron liners), and side liners for wear. Worn parts reduce efficiency and increase energy consumption. Replace them according to the manufacturer's wear limits.

● Rotor & Bearings: Manually rotate the rotor (if possible) to ensure it moves freely. Check for any unusual noise or binding.

● Drive System: Verify the tension and condition of V-belts. Check fluid levels in hydraulic systems if applicable.

● Feed Material: Know your material! Remove any tramp metal or uncrushable debris (e.g., rebar, bucket teeth) from the feed pile. The moisture content and hardness of the feed material will directly affect crusher settings and output.

Step 2: Correct Startup Sequence

Follow this order to avoid motor overload and component stress.

1. Start the discharge conveyor (ensuring a clear path for crushed material).

2. Start the screening unit (if it's part of a closed-circuit system).

3. Start the impact crusher itself. Allow the rotor to reach full operating speed (listen for smooth, consistent running).

4. Finally, start the feed system (e.g., feeder or conveyor) and begin introducing material gradually.

Step 3: Adjusting for Optimal Performance

Fine-tune these key parameters during operation.

● Rotor Speed (RPM): Higher rotor speed increases impact force, producing a finer product. Lower speeds are better for coarser aggregates and reduce wear. Operate within the manufacturer's recommended range.

● Feed Rate: Maintain a steady, controlled, and consistent feed. Avoid both starving and overloading the crusher. A starving crusher causes the hammers to collide unnecessarily, accelerating wear. An overloaded crusher chokes, reducing output and increasing power draw.

● Gap Settings: Adjust the hydraulic or mechanical gap between the rotor blow bars and the impact aprons/curtains. A smaller gap produces a finer product, while a larger gap increases capacity and outputs a coarser material. Refer to your machine's manual for adjustment procedures.

Step 4: Monitoring During Operation

Your eyes and ears are the best diagnostic tools.

● Sound: A steady, uniform crushing hum is ideal. Listen for sudden changes like metal-on-metal grinding (indicating worn liners or uncrushable material) or heavy knocking (which could signal a broken hammer or foreign object).

● Vibration: Monitor for excessive vibration, which can signal rotor imbalance (e.g., uneven blow bar wear), misalignment, or bearing issues.

● Product Output: Regularly check the discharge pile. Is the product size and gradation consistent? An unexpected change in product size often points to rapidly worn wear parts or incorrect gap settings.

● Power Draw: Monitor the crusher's amperage. A steady load indicates proper feeding. A dropping load may mean the crusher is starved, while a spiking load indicates overfeeding or potential blockage.

Step 5: Proper Shutdown Sequence

The reverse of the startup process is crucial.

1. First, completely stop the feed system and allow all material to clear the crushing chamber. This is vital.

2. Let the crusher run empty for a minute to clear any remaining debris.

3. Stop the impact crusher.

4. Stop the screening unit and discharge conveyors after all material has passed through.

Step 6: Post-Operation & Maintenance

Efficiency is maintained through consistent care.

● Perform a quick visual inspection after shutdown while the machine is accessible.

● Keep a detailed log of operating hours, maintenance performed, and wear part changes.

● Adhere to a strict, scheduled maintenance plan for lubrication, belt tension checks, and component inspections.

● Pro Tip for Peak Efficiency: For the most consistent product and highest efficiency, operate your impact crusher in a closed circuit with a screen. The screen returns oversize material back to the crusher, ensuring optimal feed size and maximizing throughput.

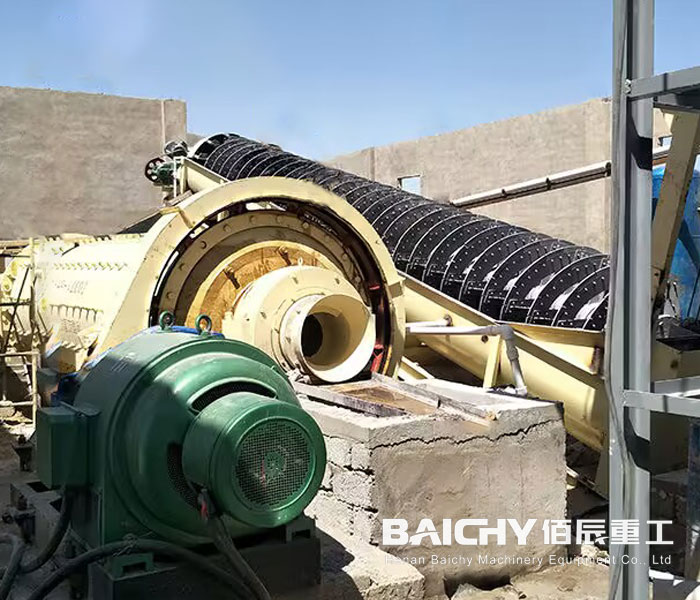

By following this structured guide, you will not only operate your impact crusher more efficiently but also extend its service life, minimize unexpected failures, and ensure a higher quality, spec product—directly boosting your operational profitability. Baichy Machinery has a history of more than 20 years. It not only produces a full set of crushing and sand making equipment, but also provides EPC project general contracting services, including plant site selection and construction, production line design and installation, and production and operation technical training. Welcome to consult online to get your exclusive stone crushing plant solution

Relative Questions About Impact Crusher

1. What is impact crusher used for?

2. How to determine the optimal discharge port size of an impact crusher?

3. How to adjust impact crusher outlet?

4. How to Plan Your Impact crusher machine Budget?

5.Comparing the 3 Best Alternatives to Impact Crushers

6.PF Impact Crusher Applications And Materials

7. 5 Things to Consider Before Buying Impact Crusher Machine

8.Breaking Down Limestone: Impact Crusher Options for 50tph,100tph,200tph,500tph

2026-01-29

2026-01-29

86-15093113821

86-15093113821

86-15093113821

86-15093113821