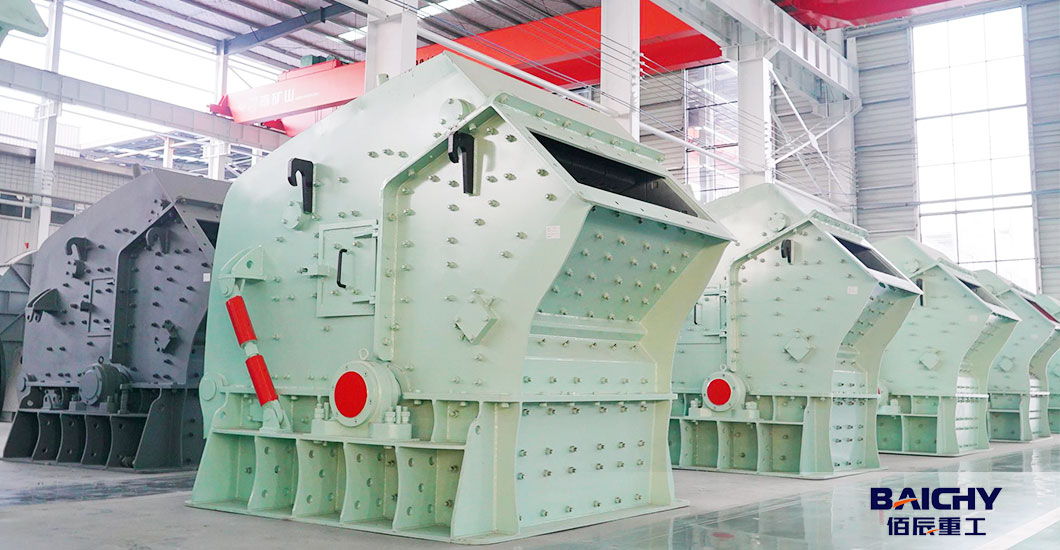

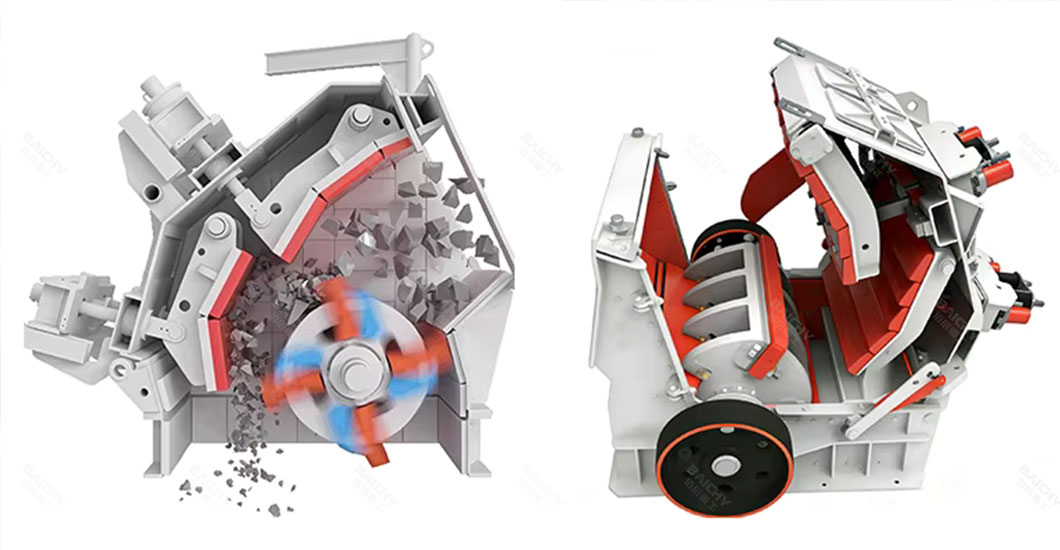

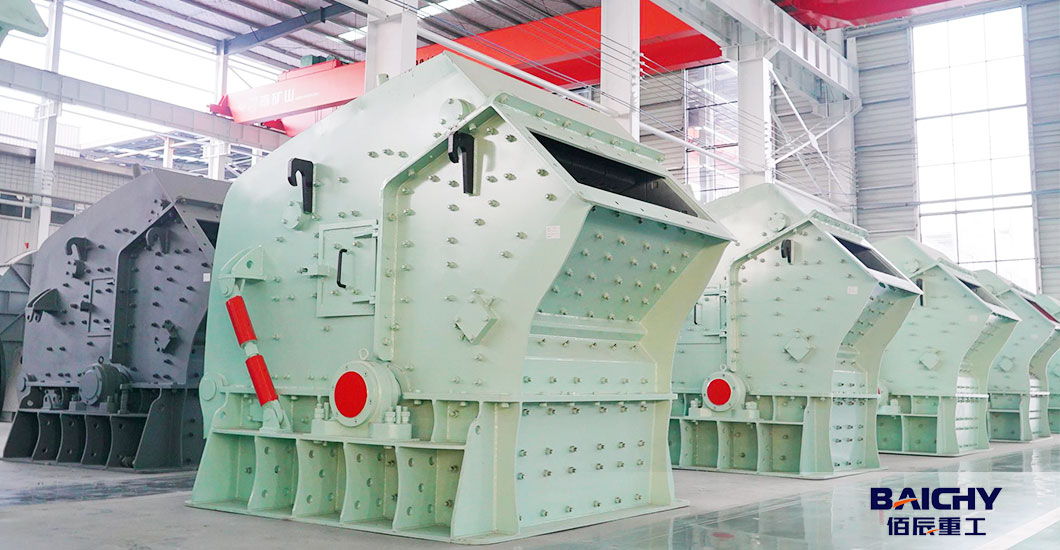

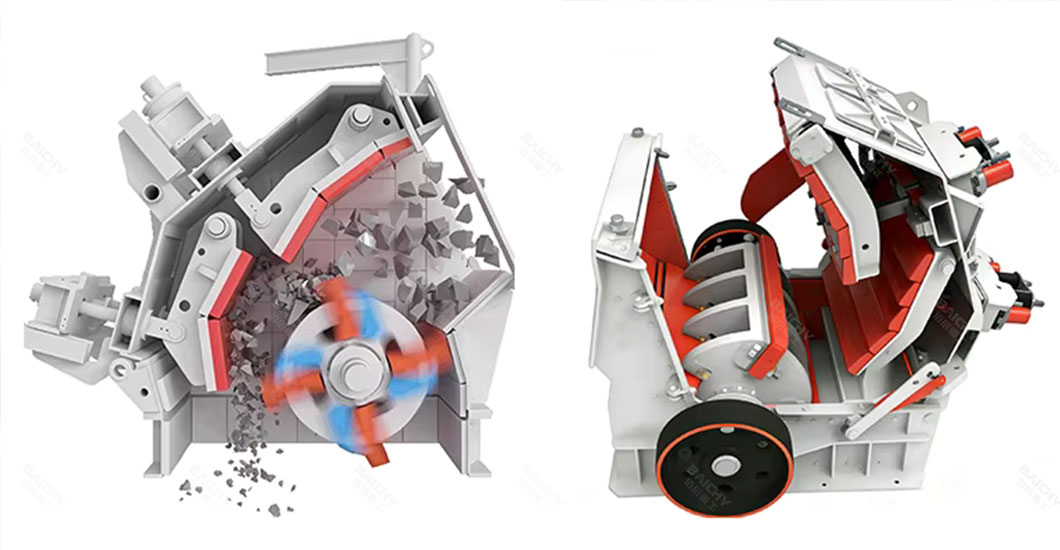

The PF Impact Crusher is a type of horizontal shaft impactor (HSI) designed to crush materials using impact energy rather than compression. Unlike jaw crushers that squeeze rock, the PF series uses a high-speed rotor fitted with heavy-duty blow bars. When material enters the crushing chamber, it is struck by these bars and thrown against impact plates (aprons) lining the chamber. This process repeats until the material reaches the desired size and falls through the discharge opening. This unique mechanism allows the PF series to handle material with moisture content better than other crushers and, crucially, produce a superior product shape.

Top Applications of PF Impact Crushers

The versatility of the PF series makes it adaptable to various stages of the production line, primarily as a secondary crusher, though larger models serve as primary crushers for softer rocks.

1. Construction & Aggregate Production

This is the most common home for the PF Impact Crusher. It is used to produce high-grade road base and building aggregates where specific particle size distribution and shape are mandatory.

2. Mining Operations

While often used for non-metallic minerals, PF crushers play a vital role in processing industrial minerals like gypsum and chemical raw materials, preparing them for grinding mills.

3. Recycling & Demolition

The recycling sector is where the impact crusher truly shines. It is extensively used to process demolition waste, effectively separating concrete from rebar (reinforcing steel) without damaging the machine, thanks to its open discharge design.

Materials You Can Process

One of the most frequently asked questions is: "What rock can I put inside a PF Impact Crusher?" The answer depends on the configuration of your wear parts, but generally, materials fall into three categories:

1. Soft to Medium-Hard Materials (Ideal Match)

The PF series is most efficient and cost-effective when processing materials with low to medium abrasion.

● Limestone: The perfect pairing. High output with low wear costs.

● Coal: Excellent for crushing coal in power plants.

● Gypsum & Phosphate: Easily reduced to fine sizes.

2. Hard & Abrasive Materials (With Care)

Can a PF crusher handle hard rock? Yes, but with conditions.

● Granite & Basalt: Modern PF crushers equipped with High-Chrome blow bars can process these hard rocks. However, operators must balance the benefit of superior product shape against higher wear part costs compared to cone crushers.

3. Recycled Materials (Rising Trend)

● Concrete & Asphalt: The impact force shatters old concrete and asphalt, stripping binders from the stone. This creates reusable "green" aggregate that bonds well in new mixes.

Why Choose a PF Series? (Key Advantages)

Why do operators continue to choose the PF Impact Crusher over other technologies?

● Superior Cubical Product: This is the #1 selling point. Impact crushing breaks rock along natural fissures, resulting in a cubical shape (not flaky or elongated). This is a requirement for high-standard highway asphalt and concrete mixing.

● High Reduction Ratio: A PF crusher can do the work of two machines, reducing material from 500mm down to 25mm in a single pass. This simplifies your plant layout.

● Versatility: It handles sticky material (when equipped with heater jackets or optimized liners) better than compression crushers, preventing clogging in wet climates.

Maintenance & Wear Parts: The Key to Efficiency

To get the most out of a PF Impact Crusher, understanding its components is vital.

● Blow Bars: The heart of the machine. Choose Manganese steel for impact resistance (recycling) or High Chrome for abrasion resistance (hard rock).

● Impact Plates: Adjustable settings allow you to control the final output size easily.

● Maintenance: Modern PF series feature hydraulic opening devices, making the replacement of liners and blow bars safe and fast, minimizing downtime.

People Also Frequently Asked For -FAQ

Q1: What is the difference between a Jaw Crusher and a PF Impact Crusher?

A: The main difference lies in the crushing method and application. A Jaw Crusher uses compression to crush hard, abrasive rock and is typically used as a primary crusher. A PF Impact Crusher uses impact energy, which produces a higher reduction ratio and a superior, cubical particle shape. It is usually used for secondary crushing or processing soft-to-medium hard materials.

Q2: Can a PF Impact Crusher handle hard rock like granite or basalt?

A: Yes, it can, but with caveats. While PF crushers are excellent for shaping hard rock to meet strict aggregate standards, processing highly abrasive materials like granite will wear out the blow bars faster than compression crushers. For hard rock, it is recommended to use High-Chrome alloy blow bars to extend wear life.

Q3: Why is the "cubical" shape produced by impact crushers important?

A: Cubical aggregate is critical for high-quality construction. Unlike "flaky" or "elongated" stones produced by some compression crushers, cubical stones bind better in asphalt and concrete mixes, providing greater structural strength. Many highway projects strictly require aggregate produced by impact crushers for this reason.

Q4: How often do I need to replace the blow bars?

A: The lifespan of blow bars depends entirely on the abrasiveness of the material being crushed. When crushing soft limestone, bars may last for months. However, when processing concrete with rebar or abrasive hard rock, they may need to be flipped or replaced much sooner. Regular inspection is essential to prevent damage to the rotor.

2026-01-19

2026-01-19

86-15093113821

86-15093113821

86-15093113821

86-15093113821