Imagine this: Instead of transporting mountains of rock to a fixed factory, what if the factory could move to the rock? The crushing train is precisely such an ingenious mobile solution that is transforming the way we produce aggregates on-site.

What Is Stone Crusher Train?

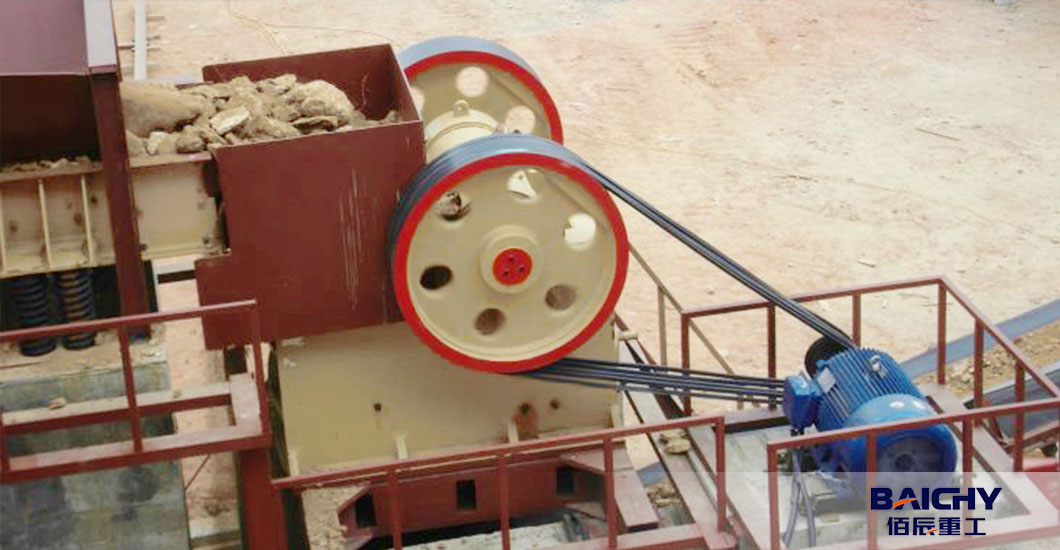

It is not a train in the true sense, but its functions are no different from those of a train. The name "train" comes from its seamless connection and sequential arrangement of mechanical equipment. You can imagine it as a production line installed on wheels or tracks. One machine feeds the material to the next, just like train carriages, each performing a specific task. It starts with a jaw crusher, which breaks down the original boulders into manageable small pieces. Then, the material (usually conveyed by a belt, which is the true connector of this "train") is sent to a secondary crusher, such as a cone crusher or an impact crusher, to further reduce the particle size. Finally, screening equipment sorts all the materials into different specifications: gravel for concrete, stones for drainage, or the perfect-sized ballast for stabilizing tracks that you need.

What are the differences between a crushing train and a stationary crusher?

The answer is simple: mobility. These devices are designed to be disassembled, transported and reassembled within days (or even hours) to suit projects that require relocation or have tight schedules - such as highway expansions, dam construction or urban renewal projects with limited space. Take the Lokotrack Urban series as an example: these compact machines produce 60% less noise pollution compared to traditional crushers, making them suitable for use in strictly regulated city centers.

Power Source: From Diesel to Solar

These mobile stone crusher plant require power, and their power sources are constantly evolving. Diesel engines have been the traditional and reliable power source, providing strong power and independence, allowing them to operate anywhere. But what's more interesting is that the industry is innovating. We now see some equipment integrating solar solutions. Imagine solar panel arrays parked beside the equipment, powering conveyor belts and screening machines, thereby reducing fuel costs and environmental footprint. This is an important step towards more sustainable construction.

The charm of the stone crushing train lies in its teamwork.

Each machine plays a specific role, just like players in a sports team. The jaw crusher, with its robust jaw plates, can handle heavy materials (as its name suggests), capable of crushing boulders up to 400 millimeters in size; while the cone crusher excels at processing aggregates into uniformly cubic particles, allowing for better integration in concrete or railway tracks. The screening machine acts as a quality control expert, ensuring only materials of the right size enter the final stockpile area - eliminating the need for on-site laborious sorting of differently sized crushed stones. Operators typically adjust the crushing process based on the type of material: granite (which is highly abrasive and hard) may require additional screening steps to reduce wear, while limestone can be processed more smoothly through a combination of jaw crusher - cone crusher - screening machine. It is this flexibility that enables the stone crushing production line to adapt to a wide range of materials, from soft sandstone to hard basalt.

The core of the stone crushing production line lies in its ultimate flexibility and intelligent logistics management. It can directly provide high-quality aggregates at the construction site for use in building foundations, road subgrades or important railway ballast. For project managers facing tight schedules, remote locations or complex and changeable construction site environments, this is not just a piece of mechanical equipment, but a strategic advantage that can truly facilitate the smooth progress of the project.

People Also Frequently Asked For - FAQ

1. What exactly is a "stone crushing train"?

It refers to a sequential line of mobile crushing and screening machinery (mounted on wheels or tracks) that works together. It acts as a portable factory, allowing you to process large rocks into aggregate directly at the job site.

2. What are the main benefits of using a stone crushing train over a stationary plant?

The biggest advantage is cost reduction. By bringing the "factory" to the raw material, you eliminate the expensive need to transport heavy rocks to a distant facility. It is also highly flexible; once a specific section of a road or mining project is finished, the entire setup can easily move to the next location.

3. What specific equipment is usually included in the lineup?

A standard setup typically operates in stages. It usually starts with a mobile jaw crusher for primary breaking (handling the biggest rocks). This feeds into a cone or impact crusher for finer shaping, followed by vibrating screens to sort the final material by size. Conveyor belts connect all these units.

4. How are these mobile crushing stations powered?

Traditionally, they rely on heavy-duty diesel engines to handle the high torque required for crushing rock. However, the industry is modernizing, and many new "crushing trains" now utilize hybrid electric systems or even solar-assisted power to reduce fuel consumption and environmental impact in remote areas.

2026-01-15

2026-01-15

86-15093113821

86-15093113821

86-15093113821

86-15093113821