How much loss has the unplanned breakdown of the crusher caused to your business? For aggregate producers, recycling enterprises or mining operations, every hour of downtime means production loss, missed delivery deadlines and waste of manpower - these costs can be as high as several thousand dollars. What is the solution? Stock up on key spare parts. Having the right components on hand can minimize downtime and keep your impact crusher running at optimal efficiency. Here is a list of essential spare parts for impact crushers and inventory management tips to protect your operations.

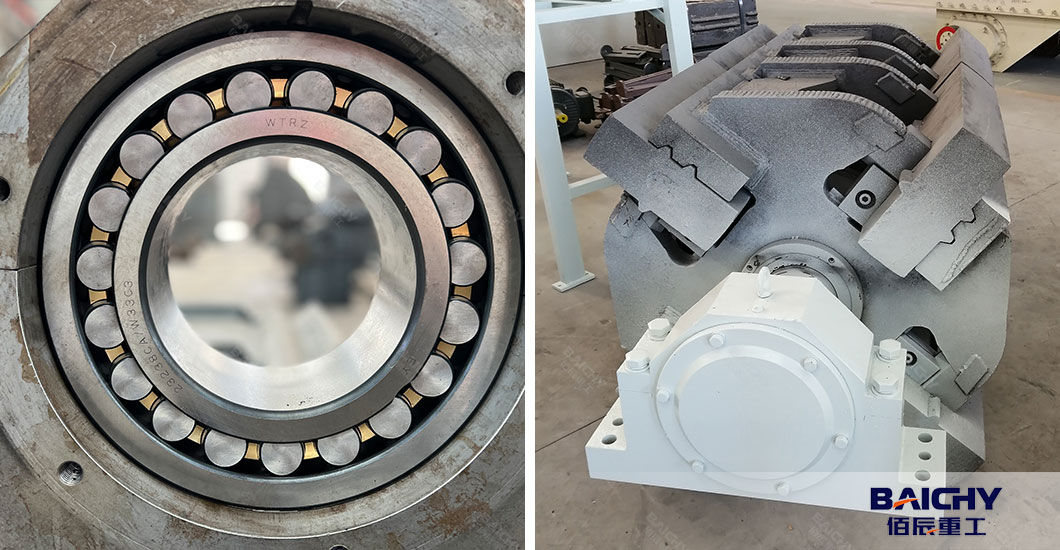

1.Rotor Assembly: Power Core of Impact Crusher

The rotor assembly is the heart of the impact crusher, responsible for generating the centrifugal force needed to crush the material. A malfunctioning rotor can shut down the entire production line – making it an essential spare part for high-volume operations.

● Core Function: The rotor (equipped with impact plates) rotates at high speed (800-1200 RPM), impacting and crushing the feed material. It is subjected to extreme mechanical stress and wear.

● Inspection and Replacement Tips: Check the rotor for imbalance (manifesting as excessive vibration), cracks in the rotor shaft, or wear in the keyway. If you notice wobbling, unusual noises, or reduced crushing efficiency, replace the rotor assembly immediately. For heavy-duty applications (e.g., 24/7 aggregate production), stock a complete rotor assembly – repairing a damaged rotor on-site can take over 8 hours, while replacement can reduce downtime to under 2 hours.

Impact Crusher Rotor Aseembly

2. Impact Plate/Hammer Kit: The Most Wear-Prone Parts

The impact plates (or hammers) are critical components of the crusher, directly impacting and crushing the material. They wear out faster than any other part – especially when processing abrasive materials like granite or quartz.

● Quick Replacement Strategy: Stock a complete set of impact plates (matching your crusher rotor size) rather than individual parts. Worn impact plates lead to uneven crushing, reduced output, and increased energy consumption.

● Pro Tip: Choose wear-resistant materials (e.g., high-manganese steel or alloy steel) for extended lifespan. Rotate the impact plates regularly (every 40-80 operating hours) to distribute wear evenly – this can extend their lifespan by 30%. When replacing parts, use genuine manufacturer's parts kits to ensure a perfect fit and prevent damage to the rotor.

Impact Crusher Plates

3 Side Liners, Impact Plates, and Bolts: Protective Barriers Against Damage

Side liners and impact plates line the crushing chamber, protecting the crusher frame from direct impact from the material. The bolts that secure these components are often overlooked, but they are crucial for safety and performance.

● Protective Function: Side liners prevent wear on the crusher body, while impact plates guide the material for secondary crushing. Loose or worn liners/impact plates can lead to frame damage and reduced crushing efficiency.

● Maintenance Focus: Inspect liners and impact plates every shift for cracks or excessive wear (replace when thickness is less than 50% of the original thickness). Tighten all bolts weekly—vibration during operation can loosen fasteners, leading to liner displacement and potential equipment damage. Keep a supply of high-strength bolts and lock washers on hand to avoid delays.

Impact Crusher Side LIners

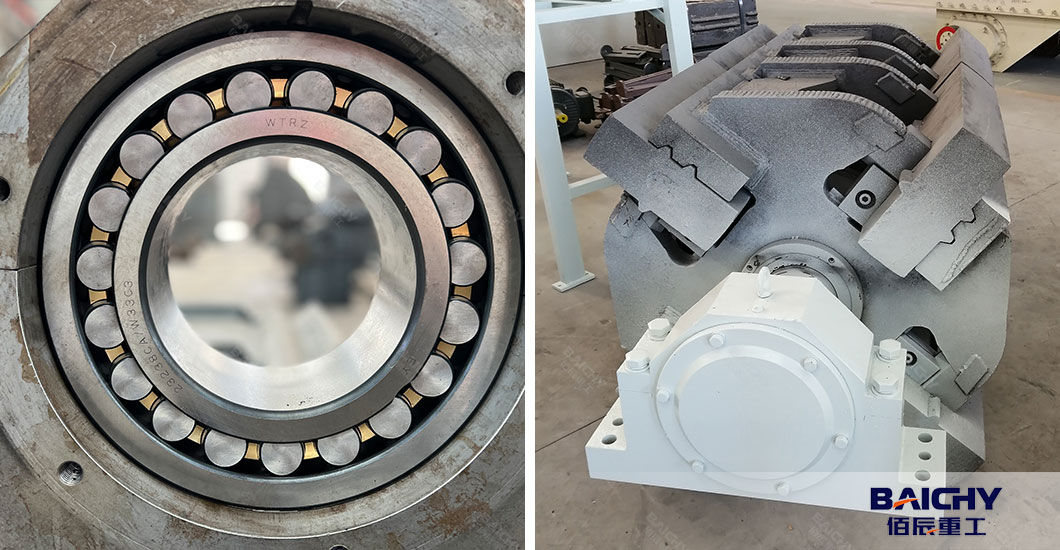

4 Bearings and Seals: Keeping Things Running Smoothly

Bearings support the rotor shaft, allowing it to rotate at high speeds with minimal friction. Seals prevent dust, debris, and moisture from entering the bearings—if the seals fail, it can lead to overheating and catastrophic failure.

● Crucial Importance: Bearings, though hidden internally, are indispensable. A seized bearing can damage the rotor shaft and motor, resulting in weeks of downtime and expensive repairs.

● Essential Spares: Keep 2-3 sets of bearings (matching your crusher model) and replacement seals on hand. Check bearing temperature daily (keep below 75°C), and replace bearings if overheating, noise, or rough rotation is detected. Always replace seals when replacing bearings—old seals will contaminate new bearings and shorten their lifespan.

Impact Crusher Bearings

5 Hydraulic/Electrical Safety Components

Hydraulic safety components (e.g., coupling fuses, pressure relief valves) and electrical components (e.g., safety filters, emergency stop switches) are often forgotten in spare parts inventory—but they are critical for preventing major failures. Key components to keep in stock:

● Coupling fuses: Protect the motor and rotor from overload (e.g., when metal debris enters the crushing chamber).

● Hydraulic safety filters: Prevent contamination of the gap adjustment system, ensuring smooth operation.

● Emergency stop switches and sensors: Ensure operator safety and shut down the crusher in case of equipment failure. Why they are important: A damaged coupling fuse can be replaced in 15 minutes – without it, you risk burning out the motor. Safety filters prevent hydraulic system failures, which can take 4-6 hours to troubleshoot and repair.

● Inventory management tips: Stock wisely, not excessively.

You don't need to stock every spare part – only the critical ones. Use these simple tips to optimize your inventory.

Inventory Management Tips: Intelligent Ordering to Avoid Excessive Stockpiling

You don't need to stockpile all the spare parts; only the key components need to be stored. Use the following simple tips to optimize your inventory:

● Determine inventory levels based on operating time: For wear-prone components (such as impact plates and liners), reserve 1-2 sets for every 500 hours of operation. For bearings and rotors, reserve 1 set for every 2000 hours of operation.

● Track wear rates: Record the replacement frequency of each component. If you are dealing with abrasive materials, increase the inventory level by 50%.

● Collaborate with suppliers: Work with your crusher manufacturer or a reliable supplier to ensure the quick delivery of non-critical components. Focus on storing components with long delivery cycles (such as rotor components) rather than those that are readily available.

● Label and organize: Store the spare parts in a clean and dry area and attach clear labels (for example, "Impact Plate - XYZ Model"). This can reduce the time spent searching for parts in an emergency.

By maintaining an appropriate level of spare parts inventory, unplanned downtime can be avoided. Storing rotor components, impact plate kits, liners, bearings and safety devices can reduce the downtime from several hours (or days) to just a few minutes of maintenance time. Remember: The cost of spare parts is insignificant compared to the losses caused by a single unplanned shutdown. Make an immediate investment in your inventory to ensure that your impact crusher operates efficiently, safely and profitably. We could supply impact crusher parts in high quality and fast delivery. Welcome to contact us for price list now.

Relative Questions About Impact Crusher

1. What is impact crusher used for?

2. How to determine the optimal discharge port size of an impact crusher?

3. How to adjust impact crusher outlet?

4. How to Plan Your Impact crusher machine Budget?

5.Comparing the 3 Best Alternatives to Impact Crushers

6.PF Impact Crusher Applications And Materials

7. 5 Things to Consider Before Buying Impact Crusher Machine

8.Breaking Down Limestone: Impact Crusher Options for 50tph,100tph,200tph,500tph

2026-01-29

2026-01-29

86-15093113821

86-15093113821

86-15093113821

86-15093113821