Impact crushers are vital equipment in aggregate production, mining, and recycling industries, known for their high reduction ratio and excellent particle shape. However, selecting the right model requires more than just comparing specifications—you need to align the crusher’s capabilities with your specific needs. This guide breaks down the key factors to consider, helping you make an informed decision that boosts efficiency and profitability.

1. Analyze Your Material

The first step in choosing an impact crusher is understanding your feed material, as it directly impacts crusher performance and durability:

● Hardness: Materials like granite, basalt (Mohs hardness 6-7+) require a robust crusher with high wear resistance. Soft materials (limestone, coal, Mohs 3-5) work well with standard models.

● Moisture Content: Wet or sticky materials (moisture >8%) can cause clogging. Opt for crushers with anti-blocking designs or adjustable rotor speeds if handling wet feeds.

● Size & Abrasiveness: Large feed sizes (over 300mm) need a crusher with a wide feed opening. Abrasive materials (quartz-rich rocks) demand wear parts (impact plates, blow bars) made of high manganese steel or alloy.

● Impurities: Avoid materials with metal scraps or hard debris—they can damage the rotor. Choose crushers with safety systems like overload protection if impurities are unavoidable.

2. Production Requirements

Define your output goals to narrow down options:

● Capacity: Calculate your required tons per hour (TPH). Impact crushers range from small 50 TPH models for small projects to 500+ TPH units for large quarries. Ensure the crusher’s rated capacity matches your peak demand.

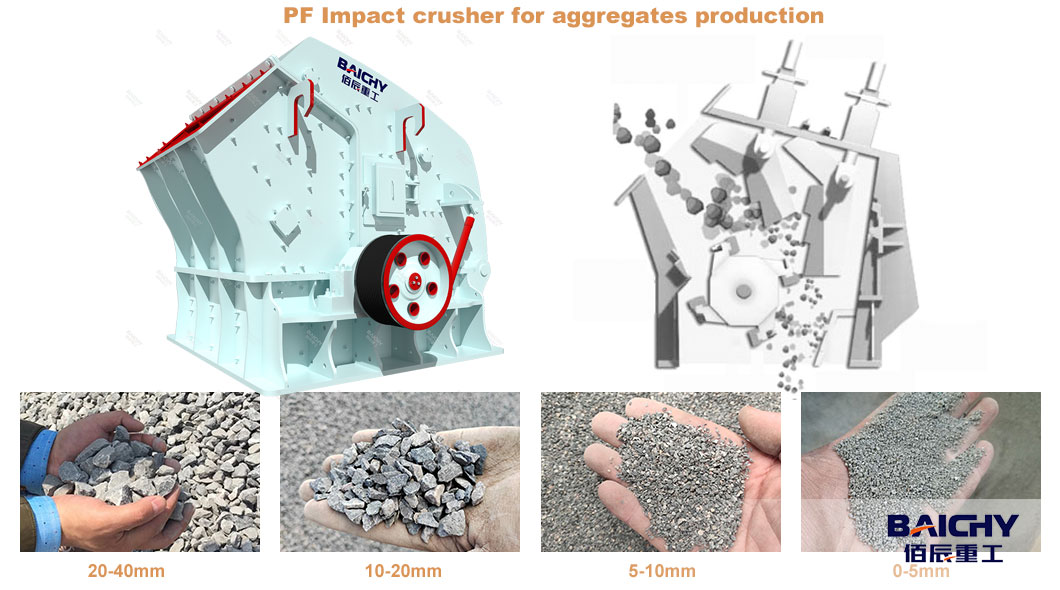

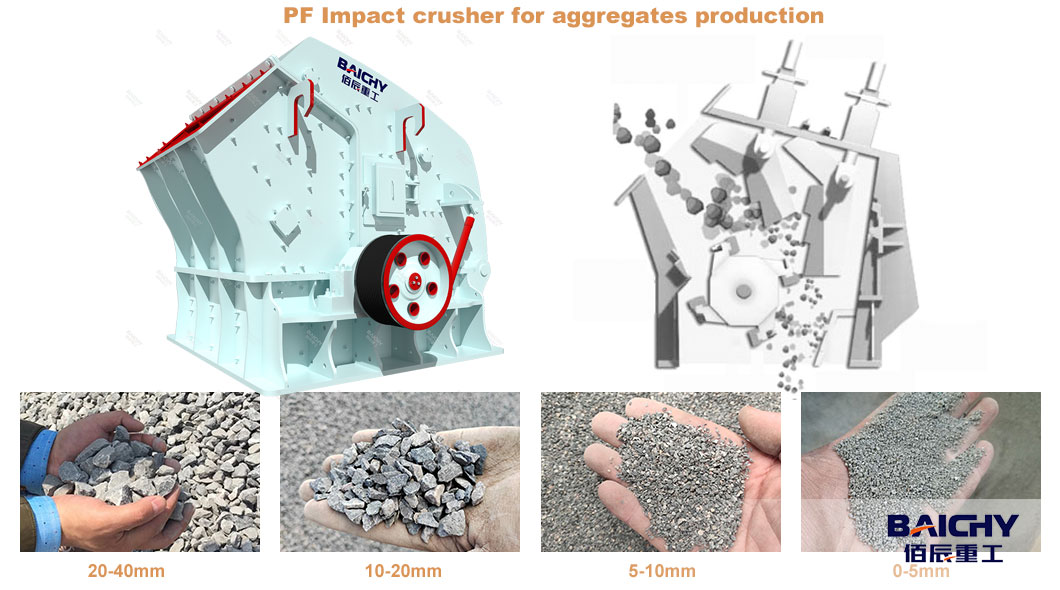

● Reduction Ratio: Need fine aggregates (10-20mm) or coarse products (40-60mm)? Impact crushers offer higher reduction ratios (10:1 to 20:1) than jaw crushers, but adjustability (e.g., hydraulic gap setting) lets you fine-tune output size.

● Space & Mobility: For on-site crushing (e.g., construction waste recycling), choose a mobile impact crusher. Fixed models are ideal for stationary quarries with ample space.

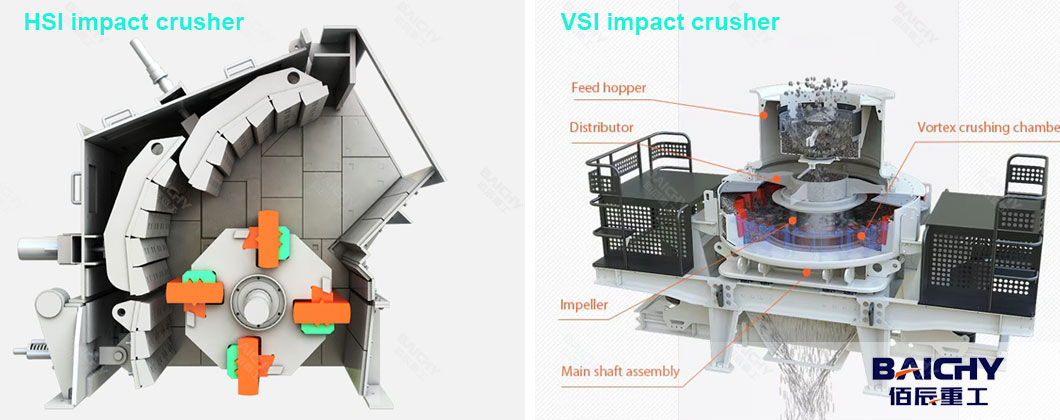

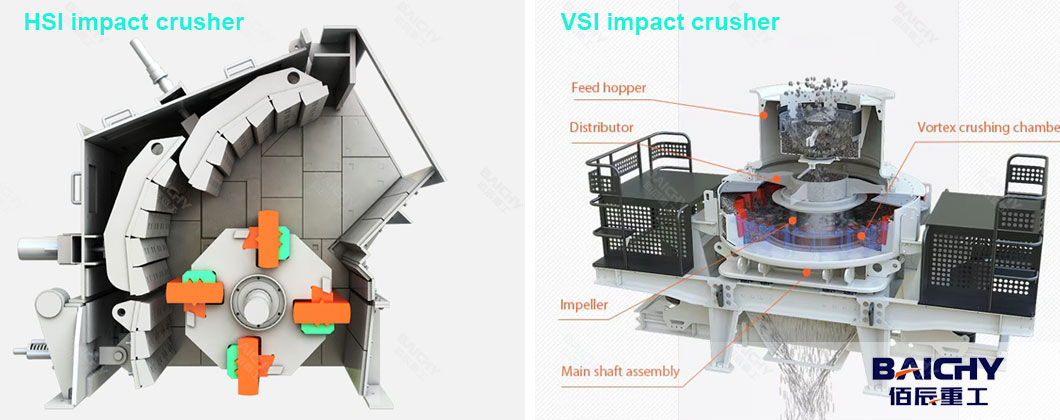

3. HSI vs. VSI: Choose the Right Impact Crusher Type

Two main types dominate the market—Horizontal Shaft Impact (HSI) and Vertical Shaft Impact (VSI) crushers. Here’s how they compare:

● HSI Crushers: Feature a horizontal rotor with blow bars. Best for medium-hard materials (limestone, concrete) and primary/secondary crushing. Advantages: high capacity, easy maintenance, and cost-effectiveness. Limitation: Less efficient for ultra-hard materials.

● VSI Crushers: Use a vertical rotor that accelerates material for impact crushing. Ideal for tertiary crushing (producing cubical aggregates) and hard materials (granite, basalt). Advantages: superior particle shape, low wear, and high efficiency. Limitation: Higher initial cost and smaller feed size capacity.

4. Product Quality & Shape

Aggregate quality directly affects project value—especially for concrete, asphalt, or road construction:

● Particle Shape: VSI crushers produce more cubical, well-graded particles (desirable for high-strength concrete). HSI crushers offer good shape but may have more elongated particles for hard materials.

● Consistency: Look for crushers with adjustable gap settings and uniform rotor speed to ensure consistent output size. Avoid models that produce excessive fines (wasting material) or oversized chunks (requiring reprocessing).

5. Maintenance & Operational Costs

Long-term costs matter as much as upfront investment:

● Wear Parts Replacement: Impact plates, blow bars, and liners are consumables. Choose crushers with easy-to-replace wear parts and check availability from suppliers. HSI wear parts are typically cheaper than VSI components.

● Energy Efficiency: Opt for models with high power-to-capacity ratios (e.g., electric motors with variable frequency drives) to reduce electricity costs.

● Maintenance Access: Crushers with hydraulic lifting systems, removable side plates, and clear service points save time on inspections and repairs.

● Lifespan: Invest in reputable brands with durable frames and rotors—cheaper models may require frequent repairs, increasing downtime.

6. Comparison: Impact vs. Jaw/Cone Crushers

Impact crushers aren’t the only option—compare them with jaw and cone crushers to confirm suitability:

● Impact vs. Jaw Crushers: Jaw crushers are better for primary crushing of hard, large materials (feed size up to 1000mm) but have lower reduction ratios and poor particle shape. Impact crushers excel at secondary crushing, offering finer output and better shape.

● Impact vs. Cone Crushers: Cone crushers are ideal for hard materials (granite, ore) and high-capacity tertiary crushing but are more expensive. Impact crushers are more versatile for medium-hard materials and produce better particle shape at a lower cost.

Choosing the right impact crusher requires balancing material characteristics, production goals, product quality, and costs. Start by analyzing your feed material and output needs, then select between HSI and VSI based on hardness and particle shape requirements. Don’t forget to factor in maintenance ease and long-term operational costs—investing in the right model will drive efficiency and ROI for years to come. Baichy Machinery Company is headquartered in Zhengzhou, Henan. As a manufacturer specializing in the production of impact crushers for more than 20 years, it has a good reputation in the industry. If you have any questions about impact crushers, please click on the online customer service to get soluiont and price list, which will answer you 24 hours a day.

2026-01-26

2026-01-26

86-15093113821

86-15093113821

86-15093113821

86-15093113821