In mining, construction, and chemical processing, achieving precise, uniform particle sizes for medium-to-fine crushing is critical—and a twin roll crusher (also called a double roll crusher) excels at this task. Unlike jaw crushers (for coarse breaking) or impact crushers (for high-speed fragmentation), twin roll crushers use gentle yet squeezing compression and shearing force to reduce materials, making them ideal for brittle, soft-to-medium-hard substances (e.g., coal, limestone, gypsum).

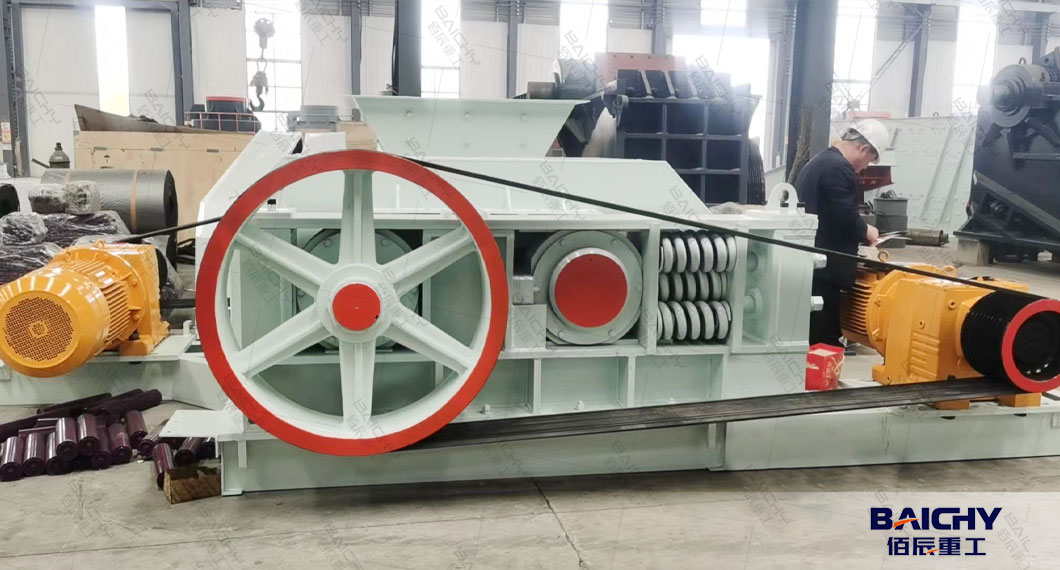

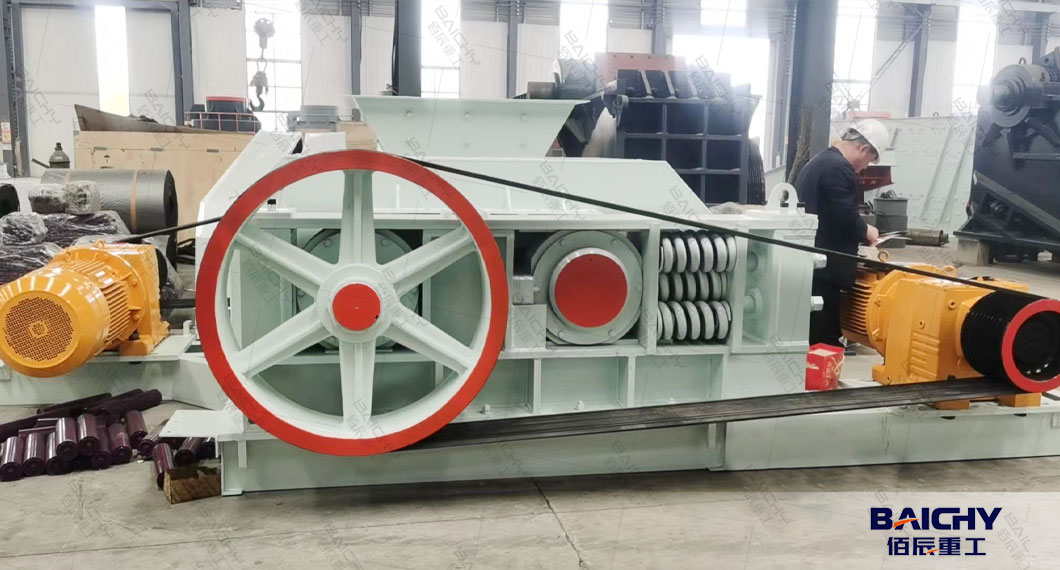

What Exactly Is a Twin Roll Crusher?

A twin roll crusher is a mechanical crushing device designed for secondary or tertiary crushing (after initial coarse crushing). Its defining feature is two parallel, counter-rotating rolls (cylinders) mounted on a sturdy frame. Material is fed into the gap between the rolls, where it is squeezed, sheared, and broken into smaller particles—with the final size determined by the adjustable gap between the two rolls.

Twin roll crushers are categorized by their roll type (smooth, grooved, or toothed) and gap adjustment method (mechanical or hydraulic), with models ranging from small lab-scale units (1–5 TPH) to industrial-grade machines (200+ TPH).

How Does a Twin Roll Crusher Work? (Step-by-Step Principle)

The working process of a twin roll crusher is straightforward but engineered for precision, ensuring efficient material reduction without waste:

1. Feeding: Controlled Material Input

● A vibrating feeder (e.g., GZD series) delivers material evenly into the feed hopper of the twin roll crusher. The feeder’s speed is synchronized with the rolls’ rotation to prevent overloading—critical for avoiding jams, especially with wet or sticky materials (e.g., clay-rich limestone).

● Most feed hoppers include a grate or screen to filter out oversized lumps (larger than the maximum roll gap + 10%) that could damage the rolls.

2. Crushing: Compression & Shear Force in Action

● The two rolls rotate in opposite directions (typically 10–30 RPM, depending on roll diameter). As material enters the gap between the rolls, it is first grabbed by the rolls’ surface (enhanced by grooved or toothed designs for slippery materials like coal).

● The rolls apply continuous compression and shear force: softer materials (e.g., gypsum) are crushed by squeezing, while brittle materials (e.g., limestone) fracture along natural weak points.

● The gap between the rolls—adjustable from 1mm to 50mm—dictates the final particle size. For example, a 10mm gap produces 10mm-max aggregate for concrete.

3. Discharge: Uniform Output Collection

● Crushed material falls freely from the roll gap onto a conveyor belt, which transports it to storage or downstream processing (e.g., screening for further grading).

● Advanced models include a scraper system that cleans the roll surfaces during operation—preventing sticky material (e.g., wet coal) from adhering and reducing efficiency.

5 Stand-out Advantages of Twin Roll Crushers

1.Precise Product Size Control: The ability to adjust the roll gap allows for the production of a consistent, cubical product with minimal oversized particles. This reduces the need for re-crushing and saves energy.

2.Low Fines Generation: Unlike impact crushers that use high-speed impact and attrition, the twin roll crusher uses a low-speed, compression-based crushing action. This results in less over-grinding and a lower generation of unwanted fine dust.

3.Simple and Robust Design: With fewer complex components than cone or impact crushers, twin roll crushers are generally easier and less expensive to maintain. Their simplicity also translates to high reliability and lower operating costs.

4.Versatility: They are capable of handling a wide range of materials, including:

Minerals: Coal, limestone, salt, gypsum, clay

Ores: Weathered or friable ores

Recyclables: Glass, coal coke, weathered aggregates

5.Built-in Safety: The overload protection system is an automatic insurance policy against catastrophic failures from uncrushable objects, protecting the machine and reducing downtime.

Twin Roll Crusher vs. Other Crushers

● vs. Jaw Crusher: A jaw crusher is ideal for primary crushing of hard, abrasive materials. A twin roll crusher is better suited for secondary/tertiary duty, handling softer to medium-hard materials and providing a more controlled product size.

● vs. Cone Crusher: Cone crushers are excellent for hard, abrasive stones but are more complex and generate more fines. Twin roll crushers offer a simpler, more economical solution for less abrasive materials where precise sizing is key.

● vs. Impact Crusher: Impact crushers are great for producing a highly cubical product but generate significant fines and wear parts costs. The twin roll crusher is chosen when a lower percentage of fines is desired, and operating costs need to be minimized.

The twin roll crusher is a time-tested, efficient, and reliable solution for size reduction tasks in mining, quarrying, and recycling. Its straightforward design, excellent control over product sizing, and cost-effectiveness make it an invaluable piece of equipment in any processing circuit.

When selecting a crusher for your specific needs, consider the material's hardness, abrasiveness, and the desired final product specification. For many applications, the twin roll crusher offers the perfect balance of performance, efficiency, and simplicity. Welcome to inquiry us to get professional solution and price online now.

2026-01-05

2026-01-05

86-15093113821

86-15093113821

86-15093113821

86-15093113821