The HGM80 ultrafine grinding mill is a specialized piece of equipment designed for producing ultrafine calcium carbonate powder, widely used in industries such as plastics, rubber, paints, coatings, papermaking, and pharmaceuticals. Below is a detailed overview of its key features, working principle, technical parameters, application in calcium carbonate plants, and considerations for selection:

1. Key Features of HGM80 Ultrafine Grinding Mill

● High Fineness Control: Capable of producing calcium carbonate powder with a fineness range of 325–2500 mesh (45–5 microns), meeting the strict particle size requirements of various downstream industries.

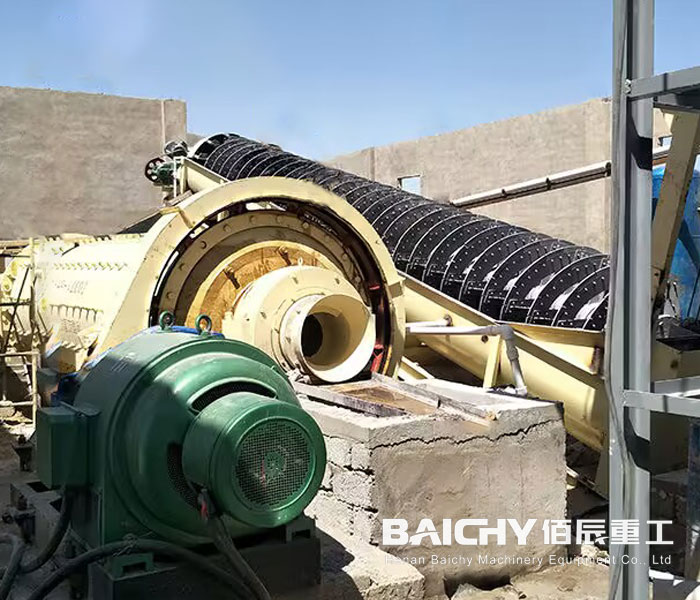

● Efficient Grinding: Equipped with a multi-layer grinding ring and roller structure, it achieves high grinding efficiency with low energy consumption compared to traditional ball mills.

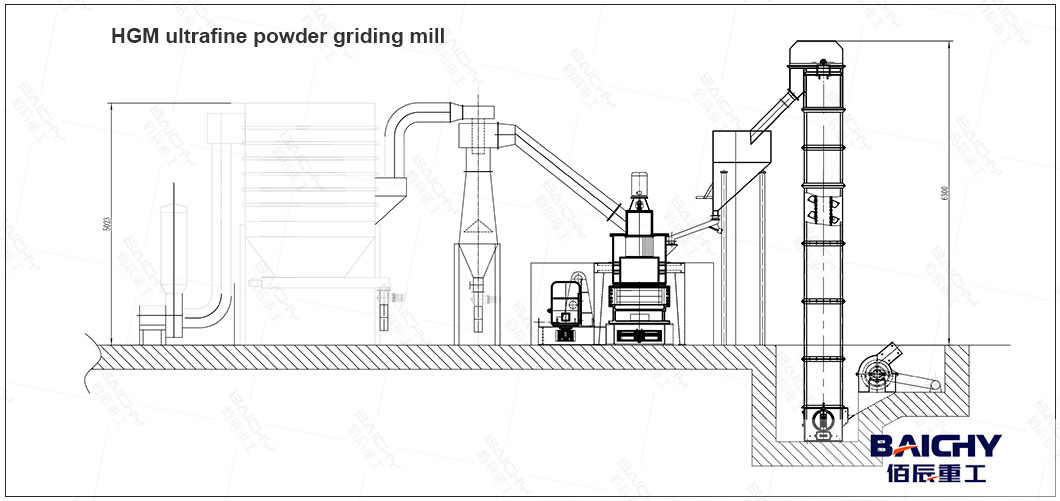

● Integrated Design: Combines grinding, classifying, and collecting functions in one system, reducing the need for additional auxiliary equipment and saving space.

● Dust-Free Operation: Equipped with a high-efficiency dust collector (e.g., pulse bag filter) to minimize dust emissions, complying with environmental protection standards.

● Easy Maintenance: The grinding rollers and rings are made of high-wear-resistant materials (e.g., high-chromium alloy), extending service life. Quick-wear parts are easy to replace, reducing downtime.

● Stable Performance: Adopts advanced frequency conversion control for the classifier, ensuring precise particle size distribution and consistent product quality.

2. Working Principle

The HGM80 ultrafine grinding mill operates through the following steps:

● Feeding: Calcium carbonate raw materials (e.g., limestone, marble) are crushed to a suitable particle size (typically ≤30mm) by a jaw crusher or hammer crusher, then fed into the mill via a vibrating feeder.

● Grinding: Inside the mill, the grinding rollers rotate and press against the grinding ring, grinding the material into fine particles through extrusion and shearing.

● Classification: A high-speed classifier (rotary impeller) separates the ground particles. Particles that meet the target fineness are carried by airflow to the cyclone collector; coarser particles are returned to the grinding chamber for re-grinding.

● Collection: The qualified powder is collected by the cyclone collector, while residual dust is captured by the dust collector to ensure clean emissions.

3. HGM80 Ultrafine Grinding Mill

● Grinding Roller Quantity: 21 pieces

● Roller Diameter: 800mm

● Production Capacity: 0.5–3.5 tons/hour (varies by fineness)

● Fineness Range: 325–2500 mesh (45–5μm) |

● Main motor: ~75kW;

● Classifier motor: ~22kW

● Overall Dimensions: ~9.6m (length) × 4.1m (width) ×6.0m (height)

● Weight: ~18–22 tons

4. Application in Calcium Carbonate Powder Plants

In a calcium carbonate powder production line, the HGM80 mill plays a core role in the grinding stage. A typical plant configuration includes:

● Pre-processing Equipment: Jaw crusher (for coarse crushing) → impact crusher/hammer mill (for fine crushing) → vibrating screen (to control particle size before grinding).

● HGM80 Grinding Mill: The primary grinding unit, converting crushed calcium carbonate into ultrafine powder.

● Auxiliary Systems:

● Air compressor and blower: Provide airflow for material transportation and classification.

● Cyclone collector: Collects the finished powder (efficiency ~95%).

● Pulse dust collector: Captures residual dust to meet environmental standards (emission ≤30mg/m³).

● Control system: PLC-based automation for adjusting fineness, feeding rate, and monitoring equipment status.

5. Advantages for Calcium Carbonate Production

● Fineness Flexibility: Easily adjustable from 325 mesh (for paper coating) to 2500 mesh (for high-end plastics or cosmetics).

● Cost-Effectiveness: Lower energy consumption (≈30–50kWh/ton for 1250 mesh powder) compared to ball mills, reducing operational costs.

● Consistent Quality: The classifier ensures narrow particle size distribution (e.g., D97 ≤10μm), critical for applications like paint viscosity control.

● Scalability: Can be integrated into multi-mill systems for larger production capacities (e.g., combining 2–3 HGM80 mills to achieve 5–10 tons/hour).

6. Considerations When Selecting

● Raw Material Hardness: Suitable for soft to medium-hard materials (calcium carbonate Mohs hardness 3, ideal for HGM80; avoid hard rocks like granite).

● Production Scale: Match the mill’s capacity (0.5–3.5 t/h) to the plant’s target output. For larger demands, consider HGM100 or HGM125 models.

● Local Environmental Regulations: Ensure the dust collector meets emission standards (e.g., EU CE, US EPA, or local certifications in regions like Southeast Asia or Africa).

● After-Sales Service: Choose manufacturers with a strong service network for timely maintenance and spare parts supply (e.g., Baichy, Liming Heavy Industry, or SBM).

In summary, the HGM80 ultrafine grinding mill is a reliable choice for medium-scale calcium carbonate powder plants, balancing efficiency, fineness control, and environmental performance. Its integration into a well-designed production line ensures high-quality ultrafine calcium carbonate powder to meet diverse industrial needs. Henan Baichy Machinery Equipment Co., Ltd. is a mining machinery manufacturer integrating R&D, production and sales. Powder grinding mill is one of its core production equipment. It has mature technology and processes, complete models and configurations, and technical engineers can tailor production line configuration plans for you. If you are interested in the grinding mill, please click on the online consultation to get solution and price now. Baichy Machinery is dedicated to serving you 24 hours a day!

2026-01-05

2026-01-05

86-15093113821

86-15093113821

86-15093113821

86-15093113821