Granite, known for its exceptional hardness (Mohs 6-7) and durability, is a top choice for high-end construction projects, such as luxury building facades, highway pavements, and precision stone products. However, processing granite into high-quality aggregates or finished stones requires a robust, high-capacity system—enter the 350TPH complex crushing and screening plant. Designed to handle granite’s abrasiveness and rigidity, this plant delivers consistent output, efficient processing, and long-term reliability. Let’s dive into its design, components, and why it’s the go-to choice for large-scale granite projects.

What is a 350TPH Complex Crushing and Screening Plant for Granite?

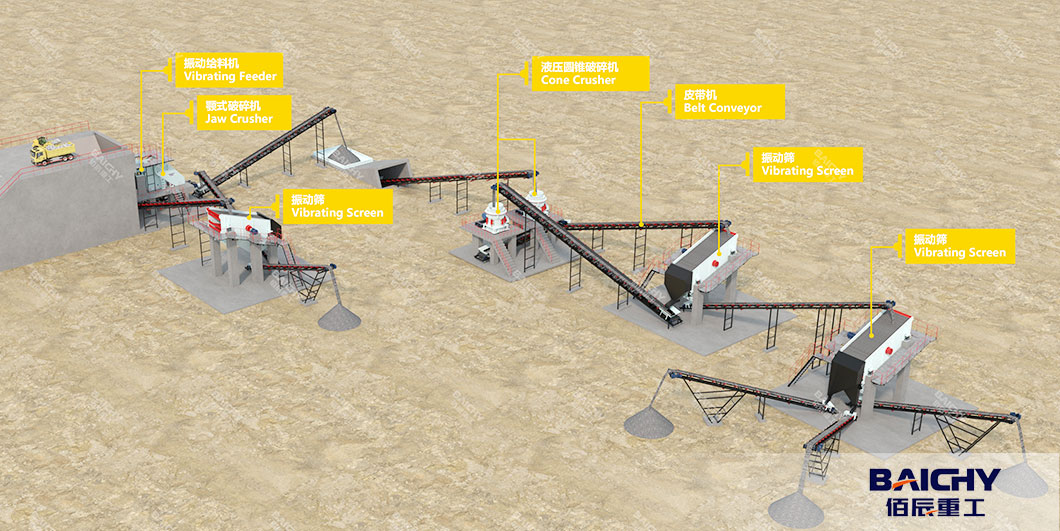

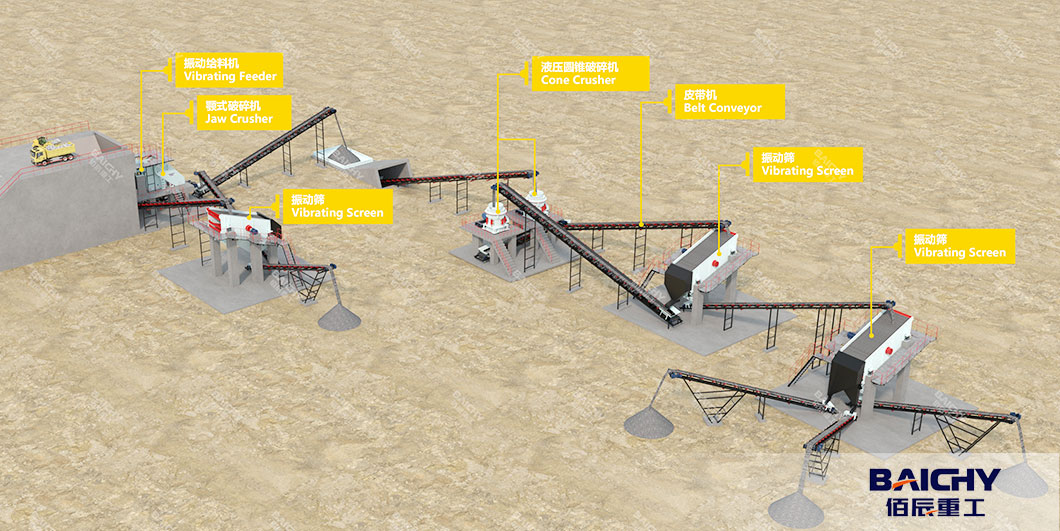

A 350TPH (tons per hour) complex crushing and screening plant is an integrated, multi-stage system engineered to process raw granite from large boulders (up to 1.2m) into graded aggregates (5-80mm) or semi-finished stone products. Unlike single-crusher setups, it combines primary, secondary, and tertiary crushing with precise screening, ensuring granite is crushed thoroughly while preserving its cubical shape—critical for construction applications. With a capacity of 350 tons per hour, it’s ideal for large quarries, construction aggregate suppliers, and stone processing factories serving high-demand markets.

Core Equipment Configuration: Tailored for Granite’s Hardness

Granite’s high hardness and abrasiveness demand wear-resistant, high-power equipment. A 350TPH complex plant for granite typically includes the following key components, each optimized for granite processing:

1. Feeding & Primary Crushing Stage

● Vibrating Grizzly Feeder (GZD 1500×6000): Delivers raw granite boulders evenly to the primary crusher, with a built-in grizzly screen to remove fine particles (≤50mm) early. This reduces unnecessary wear on the primary crusher and improves efficiency.

● Primary Jaw Crusher (PE 1200×1500): The workhorse of the plant, it crushes 800-1200mm granite boulders into 150-200mm fragments. Equipped with manganese steel jaw plates (wear-resistant, service life up to 6 months), it withstands granite’s abrasiveness and ensures high throughput.

2. Secondary Crushing Stage

● Cone Crusher (HST 500): As the core of secondary crushing, it refines 150-200mm granite into 50-80mm semi-finished aggregates. Its hydraulic adjustment system allows quick gap changes, and the high-chromium alloy concave/mantle resists wear from granite’s hard minerals (e.g., quartz). Cone crushers use compressive force—perfect for maintaining granite’s cubical particle shape, which is essential for concrete and asphalt strength.

3. Tertiary Crushing (Optional, for Fine Aggregates)

● Impact Crusher (PF 1315): For projects requiring 5-30mm fine granite aggregates (e.g., decorative stones, high-strength concrete), an impact crusher is added. It uses high-speed rotating impellers to shatter granite into uniform, cubical particles, with replaceable wear parts (blow bars) made of wear-resistant alloy.

4. Screening & Sorting Stage

● 4-Deck Vibrating Screen (4YK 2460): Separates crushed granite into 4 graded sizes (e.g., 0-5mm, 5-10mm, 10-20mm, 20-50mm). The screen’s polyurethane mesh is more wear-resistant than steel mesh for granite, extending service life by 2-3 times. Oversized particles (>50mm) are returned to the cone crusher for reprocessing, ensuring no waste.

5. Conveying & Dust Control

● Belt Conveyors (B800-B1000): 8-10 conveyors transport granite between stages, with adjustable speed to match crushing/screening rates. All conveyors have rubber belts resistant to granite’s abrasion.

● Dust Suppression System: Includes pulse bag filters (capture rate ≥99%) and water spray nozzles at crushing/screening points. This meets global environmental standards (e.g., EU ≤50mg/m³ emissions), critical for quarries near residential areas.

How the 350TPH Granite Plant Works: Step-by-Step Process

● Raw Material Handling: Granite boulders (trucked from quarries) are dumped into a hopper, then fed to the vibrating grizzly feeder.

● Primary Crushing: The jaw crusher reduces boulders to 150-200mm, which are conveyed to the cone crusher.

● Secondary Crushing: The cone crusher refines material to 50-80mm, sending it to the vibrating screen.

● Screening & Reprocessing: The 4-deck screen sorts granite into graded sizes. Oversized material loops back to the cone crusher; fine aggregates (0-50mm) go to storage silos.

Dust Control: Pulse bag filters capture dust from airflows, while water sprays reduce dust at material transfer points.

● Storage & Delivery: Graded granite aggregates are stored in silos, then loaded into trucks for delivery to construction sites or stone factories.

Key Advantages of the 350TPH Complex Plant for Granite

1. High Capacity & Efficiency

With 350TPH output, it meets large-scale demand (e.g., highway projects needing 2,000+ tons of aggregates daily). The multi-stage design reduces energy waste—each crusher handles only the size it’s optimized for.

2. Durability for Granite’s Abrasiveness

All wear parts (jaw plates, cone liners, screen mesh) use high-hardness alloys, minimizing replacement frequency. This cuts maintenance downtime to ≤2 hours/week, ensuring continuous operation.

3. Uniform, High-Quality Output

Cone crushers and impact crushers (optional) produce cubical granite aggregates with low flakiness rate (<5%). This improves concrete workability and asphalt durability, making the output popular with high-end construction clients.

4. Flexibility for Diverse Needs

The plant can be adjusted to produce different sizes:

20-50mm: Road base aggregates

10-20mm: Concrete coarse aggregates

5-10mm: Asphalt fine aggregates

0-5mm: Stone powder (used in cement or tile manufacturing)

Conclusion

The 350TPH complex crushing and screening plant is the ultimate solution for granite processing—combining high capacity, durability, and quality to turn hard granite into valuable construction materials. Whether you’re a quarry owner, aggregate supplier, or construction firm, this plant ensures efficient, profitable processing while meeting environmental and industry standards. Henan Baichy Machinery Equipment Co., Ltd. is a mining machinery manufacturer integrating R&D, production and sales. Stone crusher is one of its core production equipment. It has mature technology and processes, complete models and configurations, and technical engineers can tailor production line configuration plans for you. If you are interested in the stone crusher, please click on the online consultation to get solution and price now. Baichy Machinery is dedicated to serving you 24 hours a day!

2026-01-05

2026-01-05

86-15093113821

86-15093113821

86-15093113821

86-15093113821