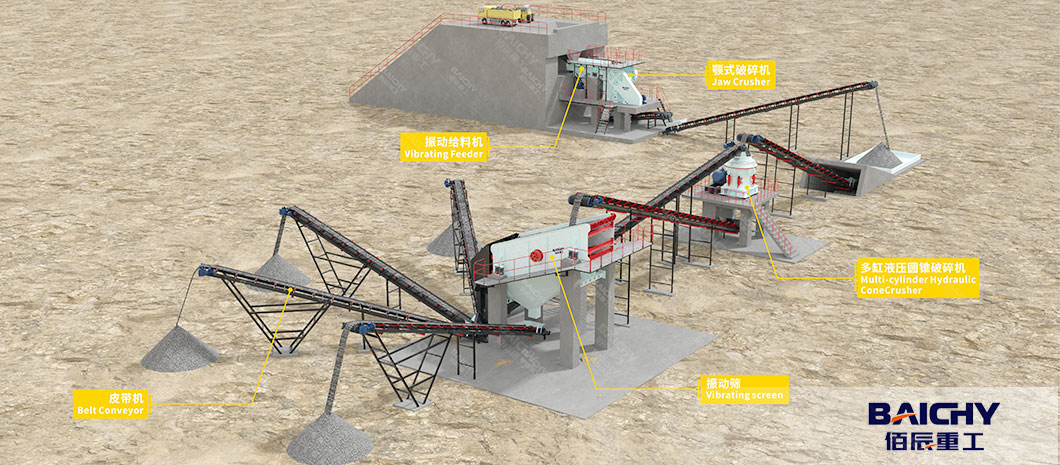

Rock stone crushing plants are the backbone of construction, mining, and infrastructure projects—transforming raw rocks (granite, limestone, basalt, etc.) into graded aggregates (5–80mm) for roads, buildings, and concrete. A smooth, optimized workflow is key to maximizing throughput, reducing waste, and ensuring consistent product quality. Whether you’re operating a small 50 TPH plant or a large 500 TPH facility, understanding the standard workflow helps streamline operations. Let’s break down the 6 core stages of a rock stone crushing plant workflow, with insights into equipment and best practices.

What is a Rock Stone Crushing Plant Workflow?

A rock stone crushing plant workflow is a sequential process that converts large, unprocessed rock boulders into usable aggregates. It combines feeding, crushing (primary, secondary, tertiary), screening, and material handling—each stage working in sync to minimize downtime and maximize efficiency. The workflow is customizable: for hard rocks (e.g., granite), it may include three crushing stages; for soft rocks (e.g., limestone), two stages often suffice. The end goal is to produce aggregates that meet specific size requirements (e.g., 10–20mm for concrete, 20–50mm for road bases).

Step 1: Raw Material Handling & Feeding

The workflow starts with preparing and feeding raw rock into the plant—critical for avoiding bottlenecks later.

Key Equipment & Process:

● Rock Stockpile: Raw rocks (excavated from quarries or mines) are first stored in a stockpile. This acts as a buffer, ensuring a steady supply even if excavation is delayed.

● Vibrating Grizzly Feeder: The feeder transports rocks from the stockpile to the primary crusher. It includes a grizzly screen (metal bars with gaps) that filters out fine particles (≤50mm) early. Removing fines prevents them from clogging crushers and reduces unnecessary wear.

● Safety Check: Operators inspect rocks for oversized debris (e.g., steel rods, large boulders >1.5m) that could damage equipment. Some plants use magnetic separators to remove metal contaminants.

● Pro Tip: Adjust the feeder speed to match the primary crusher’s capacity (e.g., 100 TPH feeder for a 100 TPH primary jaw crusher) to avoid overload.

Step 2: Primary Crushing – Reduce Large Boulders

Primary crushing is the first size-reduction stage, targeting large rock boulders (500mm–1.5m) into smaller, manageable fragments (50–200mm).

Key Equipment & Process:

● Jaw Crusher (Most Common): Uses compressive force (fixed jaw + moving jaw) to squeeze rocks until they break. Ideal for hard rocks (granite, basalt) and high-capacity operations (50–1,000 TPH). Manganese steel jaw plates withstand abrasion, lasting 6–12 months.

● Alternative: Impact Crusher: For soft-to-medium rocks (limestone, sandstone), impact crushers use high-speed impellers to shatter boulders. They produce more cubical aggregates but are less durable for hard materials.

● Outcome: Rocks are reduced to 50–200mm, ready for secondary crushing.

Step 3: Secondary Crushing – Refine to Medium Aggregates

Secondary crushing refines primary-crushed rocks (50–200mm) into medium-sized aggregates (10–50mm)—the most in-demand size for construction.

Key Equipment & Process:

● Cone Crusher: Perfect for hard, abrasive rocks. Uses a rotating cone and fixed concave to compress rocks into uniform, cubical particles. Adjustable discharge gaps let operators target specific sizes (e.g., 20–50mm for road bases).

● Impact Crusher: Better for soft-to-medium rocks (e.g., limestone). High-speed blow bars shatter rocks, producing angular aggregates ideal for concrete.

● Conveyor Belts: Transport material from the primary crusher to the secondary crusher. Belts with rubber covers resist rock abrasion, and adjustable speed controls maintain a steady flow.

● Pro Tip: For high-hardness rocks (Mohs 6+), use a cone crusher—impact crushers will experience rapid wear, increasing maintenance costs.

Step 4: Tertiary Crushing (Optional) – Produce Fine Aggregates

Tertiary crushing is optional but essential for projects needing fine aggregates (5–10mm) for high-strength concrete, asphalt, or decorative stones.

Key Equipment & Process:

● Vertical Shaft Impact (VSI) Crusher: Uses centrifugal force to accelerate rocks against a crushing chamber, producing ultra-fine, cubical aggregates. Ideal for 5–15mm output.

● Hammer Mill: For soft rocks (e.g., coal gangue), hammer mills use swinging hammers to grind material into fine particles (5–10mm).

● When to Use: If your plant supplies ready-mix concrete plants or asphalt manufacturers, tertiary crushing is a must to meet their fine aggregate needs.

Step 5: Screening – Separate Aggregates by Size

Screening ensures aggregates meet precise size standards—critical for quality control. Oversized particles are returned to crushers for reprocessing, while graded aggregates move to storage.

Key Equipment & Process:

● Vibrating Screens: Most plants use 2–4 deck screens (layers of mesh with varying gap sizes). For example:

Top deck (50mm gap): Catches oversized particles (>50mm) → returned to secondary crusher.

Middle deck (20mm gap): Separates 20–50mm aggregates (road bases).

Bottom deck (10mm gap): Separates 10–20mm aggregates (concrete).

Fine screen (5mm gap): Collects 5–10mm fines (asphalt).

● Polyurethane Mesh: More durable than steel mesh for abrasive rocks (e.g., granite), lasting 2–3 times longer.

● Outcome: Uniformly graded aggregates ready for storage or delivery.

Step 6: Finished Product Handling & Storage

The final stage involves storing and preparing aggregates for delivery to clients.

Key Equipment & Process:

● Belt Conveyors: Transport graded aggregates to dedicated storage silos or stockpiles (e.g., 20–50mm silo, 10–20mm silo).

● Storage Silos: Steel or concrete silos (50–500 ton capacity) protect aggregates from weather (rain, dust) and ensure a steady supply for packaging.

● Packaging/Delivery:

Bulk Delivery: Aggregates are loaded into trucks via conveyor belts for large clients (e.g., highway contractors).

Bagged Delivery: Automatic bagging machines fill 25kg or 50kg bags for small-scale clients (e.g., local builders, DIY stores).

● Dust Control: Pulse bag filters or water sprays capture dust during conveying and storage, complying with environmental regulations (e.g., EU ≤50mg/m³ emissions).

Workflow Optimization Tips for Rock Stone Crushing Plants

● Match Equipment to Rock Type: Use jaw + cone crushers for hard rocks; jaw + impact crushers for soft rocks.

● Maintain Steady Feed Rate: Avoid overloading crushers—use load cells on feeders to monitor material flow.

● Regular Maintenance: Inspect crusher wear parts (jaw plates, cone liners) weekly and replace them before they fail.

● Automate Where Possible: Use PLC control systems to adjust crusher gaps, feeder speeds, and screen operation—reducing human error.

Conclusion

The rock stone crushing plant workflow—from raw material feeding to finished product delivery—is a coordinated process that relies on the right equipment and careful optimization. By following the 6 core stages and tailoring the workflow to your rock type and capacity needs, you can run an efficient, profitable plant that delivers high-quality aggregates for construction and mining projects.

2026-02-07

2026-02-07

86-15093113821

86-15093113821

86-15093113821

86-15093113821