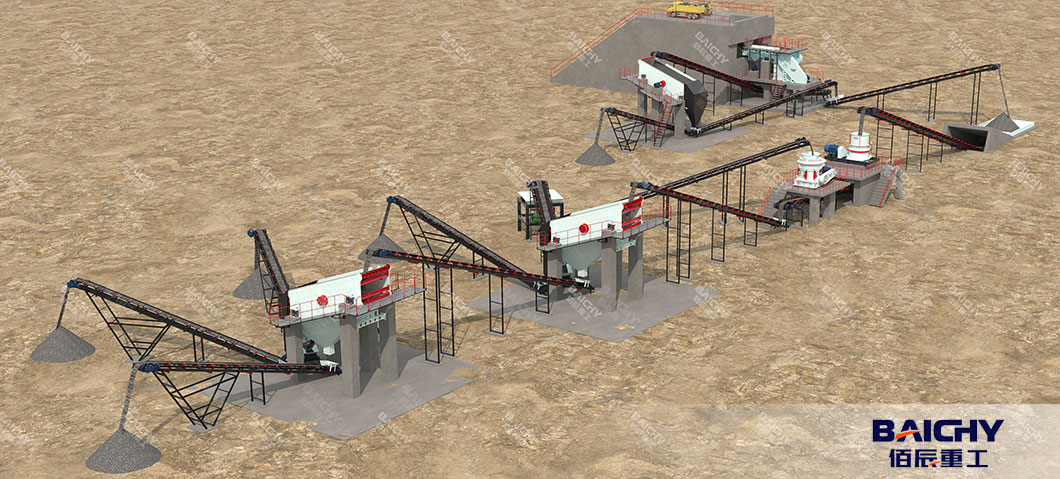

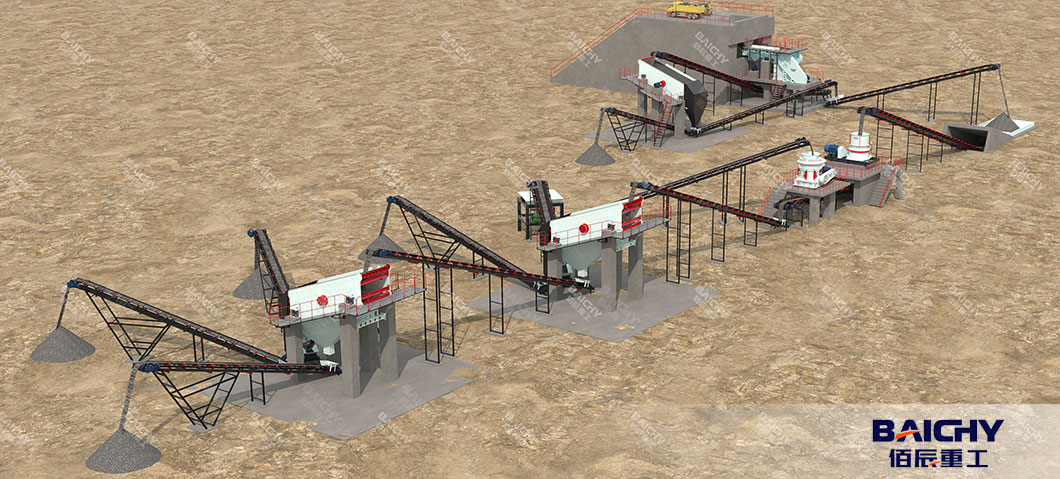

A 300TPH river boulders stone crusher plant is a complex system designed to efficiently process large, hard river boulders into graded aggregates. Its key components work in tandem to handle feeding, crushing, screening, conveying, and environmental control. Below is a detailed breakdown of each critical component:

1. Feeding System: Ensuring Continuous Material Supply

The feeding system manages the initial handling of river boulders (often mixed with silt, sand, or debris) and delivers them uniformly to the primary crusher.

● Vibrating Feeder (e.g., GZD 1500×6000):

A heavy-duty feeder with a vibrating motor that moves boulders (up to 800mm in diameter) from the hopper to the primary crusher. It includes a grizzly screen (a grid of bars) to separate fine sediments (sand, silt) from large boulders, preventing clogging in downstream equipment and improving crushing efficiency.

● Storage Hopper with Hydraulic Gate:

A large-capacity hopper (50–80 tons) stores incoming boulders, ensuring a steady supply even during intermittent delivery (e.g., from trucks or excavators). The hydraulic gate controls the feed rate to match the primary crusher’s capacity, avoiding overload.

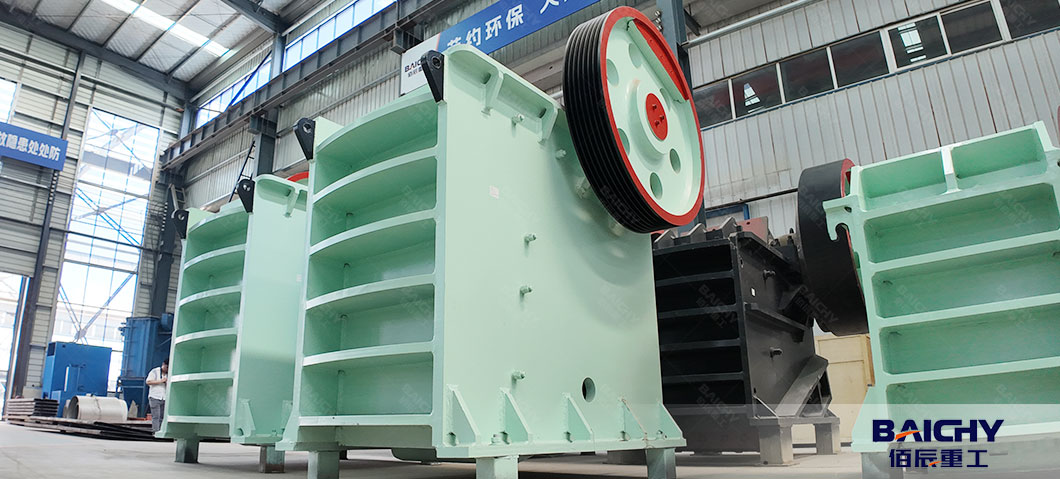

2. Primary Crushing Unit: Breaking Large Boulders

This stage reduces massive river boulders (800mm+) to smaller, manageable fragments (150–200mm) for further processing.

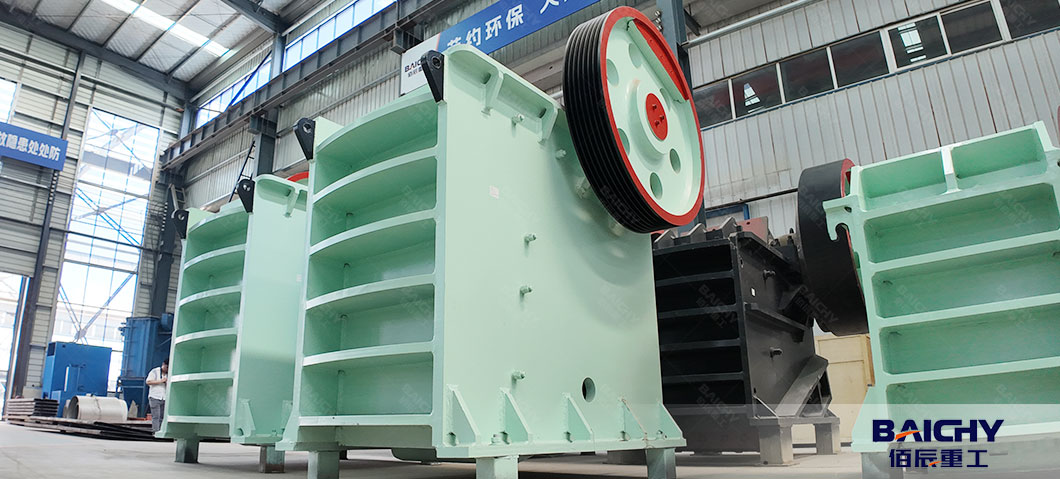

● Jaw Crusher (e.g., PE 900×1200):

The workhorse of the plant, featuring a fixed jaw and a movable jaw that crushes material through compressive force. Its robust design (manganese steel jaws) withstands the abrasiveness of river boulders (which may contain gravel or hard minerals) and delivers a high throughput (300–400 TPH), making it ideal for primary crushing.

3. Secondary Crushing Unit: Refining Aggregate Size

After primary crushing, the material is further reduced to the desired aggregate sizes (typically 20–50mm) for construction use.

● Cone Crusher (e.g., HPC 500):

A high-efficiency crusher that processes 150–200mm material into cubical, well-graded aggregates. It uses a rotating cone within a fixed concave to crush material through compression, excelling at handling hard, irregular river boulders. It produces minimal flaky particles, critical for high-quality concrete or road base materials.

● *Alternative (for softer boulders)*: Impact Crusher (e.g., PF 1520):

Uses high-speed rotating impellers to strike and shatter material, enhancing particle shape. Suitable for projects requiring rounded aggregates (e.g., asphalt).

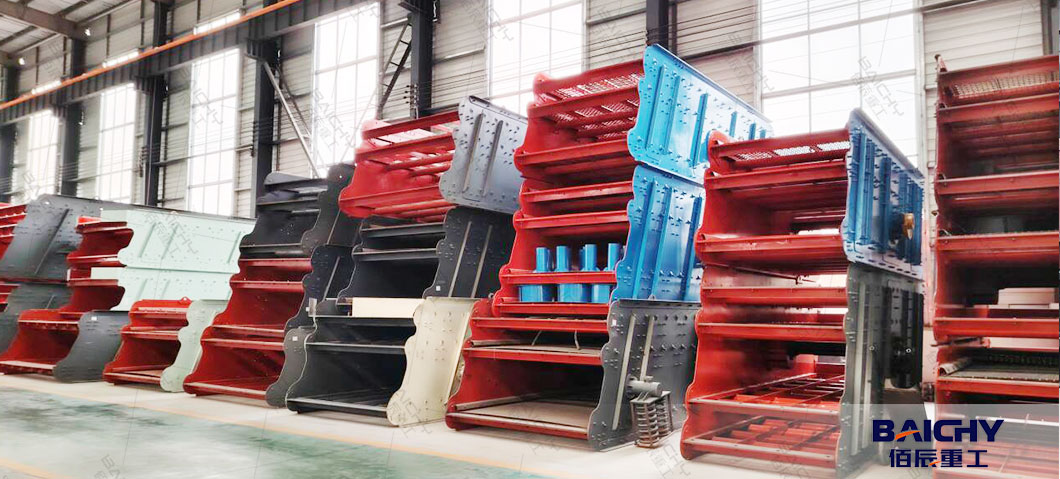

4. Screening System: Classifying Aggregates by Size

Screening separates crushed material into specific grades (e.g., 0–5mm, 5–10mm) to meet construction standards.

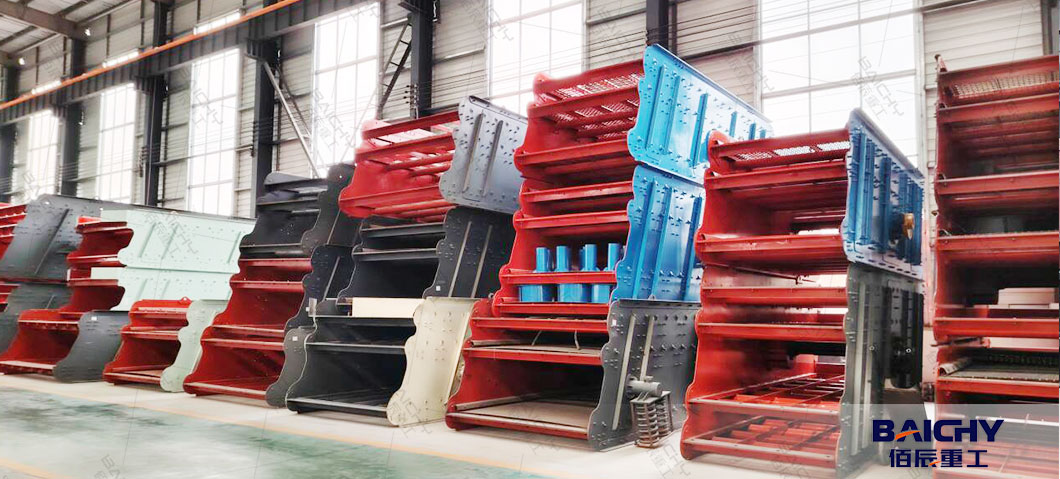

● Vibrating Screen (e.g., 3YK 2470):

A multi-deck (4-deck) screen with vibrating motors that shakes material over layered mesh screens. It classifies output into 4 common grades:

- 0–5mm (fine sand, for mortar)

- 5–10mm (fine aggregate for concrete)

- 10–20mm (coarse aggregate for concrete)

- 20–50mm (road base or ballast)

Oversized material (>50mm) is recycled back to the secondary crusher via a return conveyor for reprocessing, ensuring no waste.

5. Conveying System: Transporting Material Between Stages

Belt conveyors link all components, ensuring seamless material flow through the plant.

● Belt Conveyors (1000mm width):

Heavy-duty conveyors with rubber belts transport material from the feeder to the primary crusher, from primary to secondary crusher, from the crusher to the screen, and from the screen to stockpiles. Covers are often added to reduce dust emissions (critical for compliance with environmental regulations in the Philippines).

6. Stockpiling System: Storing Finished Aggregates

Finished aggregates are stored in separate piles by grade for easy loading and delivery.

● Tripper Conveyors:

Mobile conveyors that distribute material into designated stockpiles, preventing cross-contamination of different aggregate grades. Stockpiles are typically designed to hold 1–2 days of production (2,400–4,800 tons) to buffer against delivery delays.

7. Dust Suppression & Environmental Control

River boulders often contain dry silt or sand, leading to dust during crushing and conveying. These systems ensure compliance with local regulations (e.g., Philippines DENR standards).

● Sprinkler Systems:

Installed at transfer points (e.g., feeder outlet, crusher discharge, screen inlets) to wet material and suppress dust.

● Pulse Bag Filter:

A high-efficiency dust collector that captures fine particles from crusher chambers and conveyor belts, ensuring emissions ≤50mg/m³ (meeting air quality standards).

8. Control System: Automating Operations

A centralized control system optimizes plant performance and reduces manual intervention.

● PLC :

Monitors real-time data (throughput, motor load, screen efficiency) and adjusts settings (e.g., feeder speed, crusher gap) to maintain 300TPH output. It includes alarms for faults (e.g., overload, belt misalignment) and allows remote monitoring, simplifying troubleshooting.

Summary of Key Components

Each component plays a critical role in converting raw river boulders into usable aggregates:

- Feeding system: Uniform delivery and debris removal.

- Primary crusher: Reducing large boulders.

- Secondary crusher: Refining aggregate size and shape.

- Screening system: Classifying into grades.

- Conveyors: Transporting material between stages.

- Stockpiles: Storing finished products.

- Dust control: Ensuring environmental compliance.

- PLC system: Automating and optimizing operations.

Together, these components enable the plant to reliably produce 300 tons of high-quality aggregates per hour, supporting large-scale construction projects in the Philippines. Henan Baichy Machinery Equipment Co., Ltd. is a mining machinery manufacturer integrating R&D, production and sales. Stone crusher is one of its core production equipment. It has mature technology and processes, complete models and configurations, and technical engineers can tailor production line configuration plans for you. If you are interested in the stone crusher, please click on the online consultation to get solution and price now. Baichy Machinery is dedicated to serving you 24 hours a day!

2026-01-06

2026-01-06

86-15093113821

86-15093113821

86-15093113821

86-15093113821