Stone crusher is an indispensable part of quarry crushing or mining plants to produce construction material, such as base gravel or concrete and asphalt mixes. This crushed stone is used in a variety of applications, ranging from landscaping to highway construction. Today, we will go through different stone crusher types and top manufacturers in the world, breaking down everything you need to know and to help you land on the right one for your project.

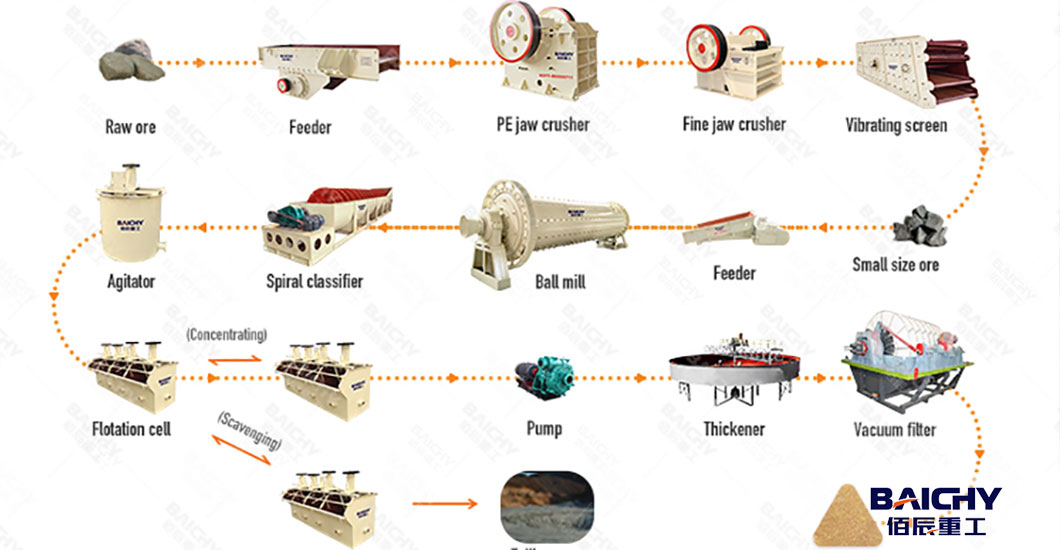

Stages of Complete Stone Crushing Plant

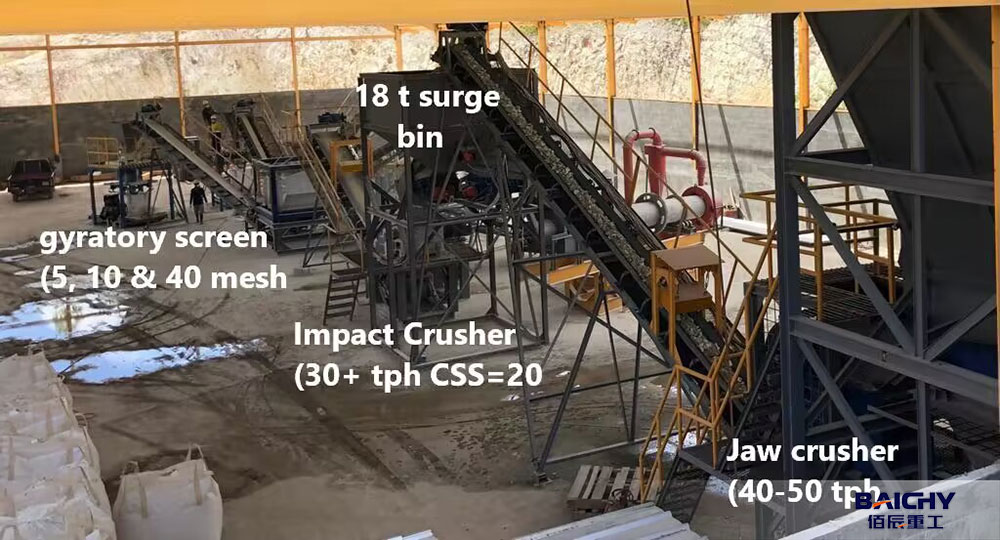

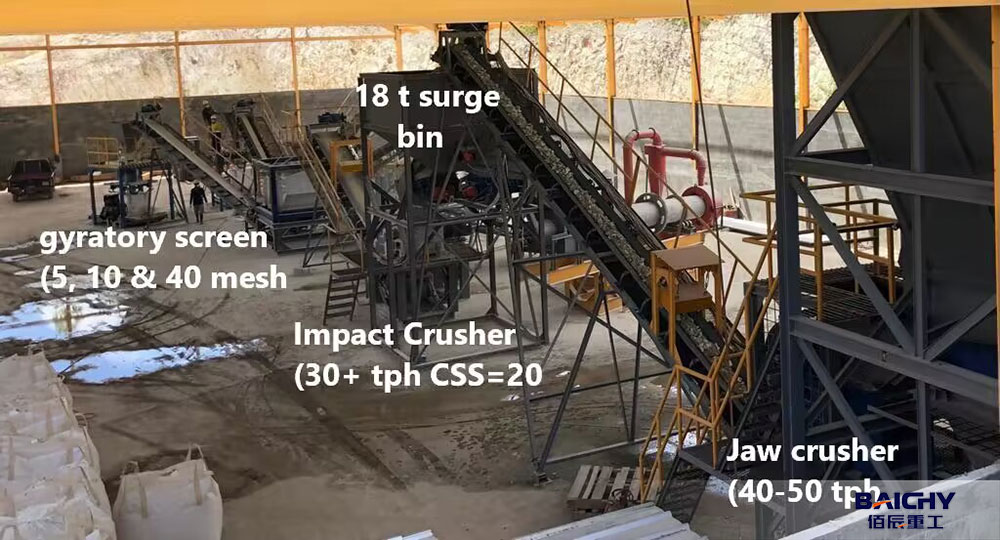

It is common to use multiple stone crusher types within a project and set them up as stations in a circuit format to perform the necessary material reduction work. In many cases, primary, secondary, and tertiary, and quaternary stations are installed to reduce the rock to the desired size, shape, and consistency.

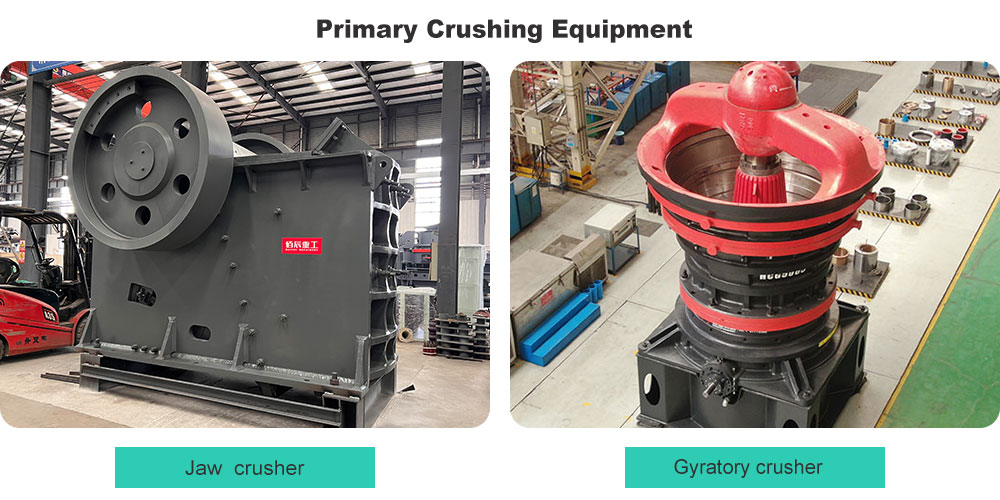

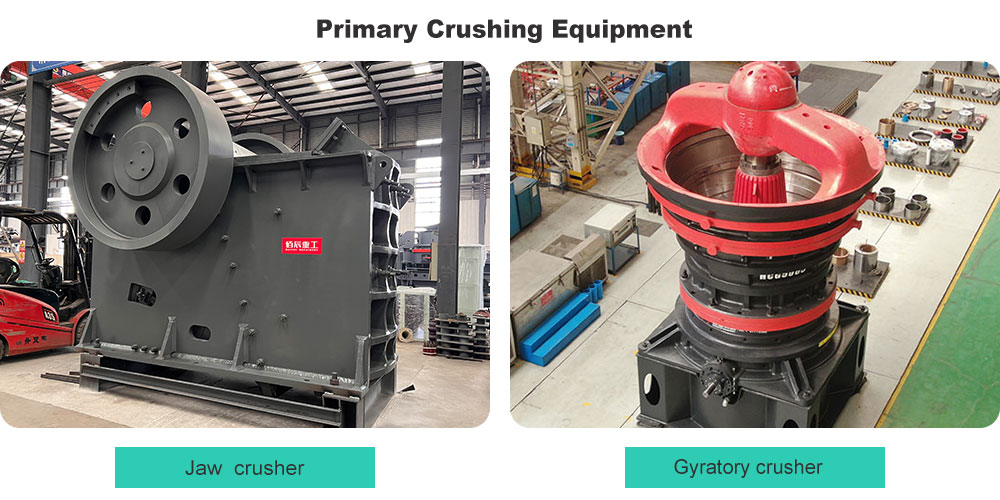

1. Primary Crushing

As the first stage in a stone crushing circuit following extraction from a mine site, primary crusher reduces material to a size and shape that can be handled by the secondary crusher. Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Jaw crusher and gyratory crusher are most often appropriate as primary crushing equipment types.

● Jaw crusher: All jaw crushers work through compression. In a V-shaped alignment, a fixed jaw is the stationary breaking surface. A moveable "swing jaw" exerts the force on the material to crush it. It is used to crush large rocks into smaller rocks, gravel,or sand.

● Gyrator crusher: A gyratory crusher is a large crushing machinery, using the gyratory sports in casing cone cavity of crushing cone to produce extrusion, fracturing and bending role to materials for crushing ore or rock of various hardness.

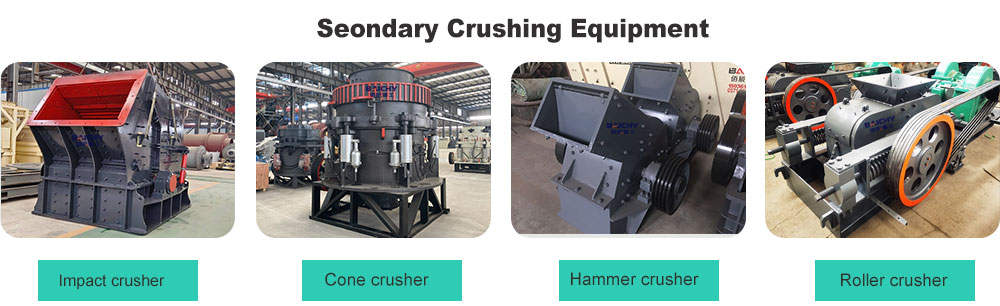

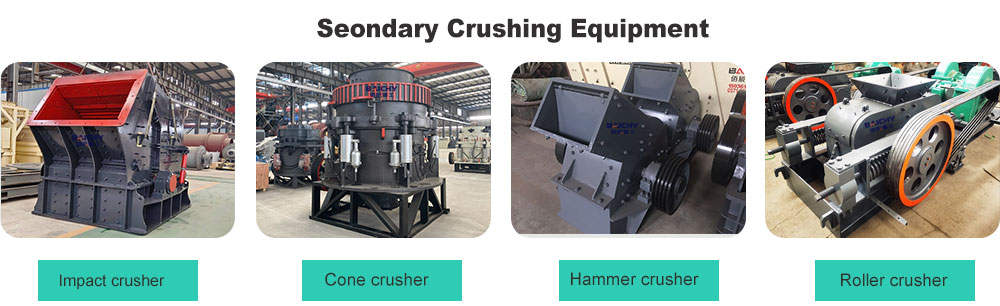

2. Secondary Crushing

In secondary crushing, reduction ratios become an essential consideration. Knowing just how fine you need your final output to be, along with the feed requirements of your tertiary or final reduction crushing station, will help you determine how much reduction needs to take place within this stage.

● Impact crusher: Impact crusher can crush both hard and soft material, even if it contains moisture. They are used for both medium and fine crushing below hardness.

● Cone crusher: It is often placed within the secondary crushing station because they are versatile in terms of feed, closed side setting, speed, and throw. With cone crushers, though, it is essential to operate them at consistent choked settings to keep productivity up.

● Hammer crusher: This type of stone crusher plant involves a high-speed rotary machine suitable for crushing medium hardness material. They have high crushing efficiency and the resulting material has a bit of powdery texture.

● PCX fine crusher: PCX fine crusher is kind of hammer crusher to crush limestone, cement, quartz etc. Due to more wear-resistant hammerhead and larger capacity, it is used to making artifical sand and gravels too.

● Roller crusher: Double-Roll Crushers are designed for medium to soft materials and consist of two cylindrical rolls that rotate in opposite directions.

3. Tertiary/Final Reduction Crushing

The goal of the tertiary or final reduction stage of the crushing process is to size and shape rock or other material into a marketable product. There may be overlap between stages in terms of which crusher styles work best.

Vertical shaft impact crusher (VSI) or even high-pressure grinding roll crushers may be used in the final reduction position.

● VSI vertical shart impact crusher : These are hydraulic impact sand-making machines that convert rock, pebbles, and sandstones into varying size grains.

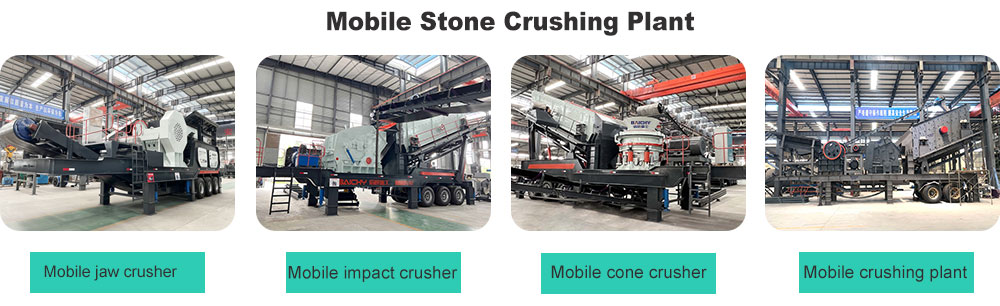

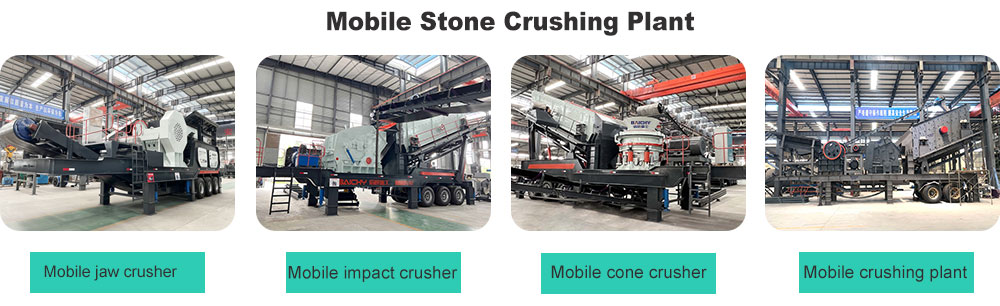

4.Mobile stone crushing plant

Mobile stone crushers are accounted as presently the most advanced aggregate-making equipment. As the name suggests, these machines can be moved easily from one work site to another, aimed to reduce transportation and operational expenses greatly, substituting fixed crushers or crushing lines. All types of stone crushers mentioned above with vibrating screen and belt conveyor could be made into mobile crushing plant.

Top Crusher Manufacturers

After we know the main stone crusher types, who are top stone crusher manufacturers in global?

1.Terex

● Country: USA

● About the company: Terex is a diversified global manufacturer that specializes in lifting and material handling equipment. It operates through two business sectors: aerial platforms and material handling. The company offers reliable customer-driven solutions for a wide range of commercial applications, including construction, infrastructure, quarrying, mining, freight, transportation, oil refining, energy, and utilities industries. Since establishing a joint venture in China in 1988, Terex has been focused on expanding its business in the country. It has successfully established a number of wholly-owned and joint ventures in Baotou, Changzhou, Shanghai, Quanzhou, and Zhangzhou. Terex is committed to providing globally reliable and safe products.

2. Sandvik

● Country: Switzerland

● About the company: Sandvik is a global high-tech engineering group with approximately 37,000 employees committed to enhancing customer productivity, profitability, and sustainability. The Sandvik Group comprises four core business organizations, each responsible for its R&D, production, and sales. These include:

2-1 Sandvik Manufacturing and Processing Solutions, the world’s leading manufacturer of metal cutting tools and tool systems, made of cemented carbide, diamond, cubic nitriding shed, special ceramics, and other hard materials.

2-2 Sandvik Mine and Rock Technology, the world’s leading supplier of equipment, drilling tools, spare parts, services, and technical solutions for the mining and engineering industries.

2-3 Sandvik Rock Processing Technology, the world’s leading supplier of rock and ore processing equipment, drilling tools, spare parts, services, and solutions, with applications covering crushing screening, crushing, and demolition.

2-4 Sandvik Materials Technology, the world’s leading material supplier, providing advanced stainless steel and special alloy products for demanding industries. The product range is wide, including pipes, rods, and strips, as well as industrial heating products and systems.

3. Metso Outotec

● Country: USA

● About the company: Metso Outotec, a new and unique company specializing in mineral processing, metal processing, and recycling, has officially started its operations. The company offers crushing and screening equipment for aggregate production, as well as solutions for mineral processing, metal smelting, chemical processing, and metal and solid waste recycling.

4. Kleemann

● Country: Germany

● About the company: Kleemann has always been renowned for its innovative strength and high-quality products, which offer enormous business benefits to professional users. As a member of Wittgen Group, an international company that specializes in construction machinery, Kleemann owns five famous brands, namely Wittgen, Vogler, Hummer, Craig Trowel, and Penninghoff. Its headquarters are located in Germany, and it has factories in Brazil, China, and India.

5.Rubble Mater

● Country: USA

● About the company: RUBBLE MASTER offers a range of top-quality, high-performance mobile crushing and screening solutions for recycling, demolition, quarrying, mining, and contracting applications. RM’s all-mobile equipment meets the highest specifications for mobility and versatility, both on-site and on-road.. For 30 years, the company designs and manufactures a robust fleet of mobile screen units, crushers, and stockpiling conveyors for the mineral processing, aggregates, and material recycling industries.

From our prospective, the brands mentioned above are the world’s top motor grader manufacturers. They have one thing in common, which is their great reputation earned from satisfied clients all around the world.

Evaluate your needs before making a purchase

When it comes to buying a crusher, there are several factors to consider. It is important to take the time to evaluate your needs before making a purchase.

1.Type of Crusher

The first thing to consider is the type of crusher you need. There are several types available, including jaw crushers, cone crushers, impact crushers, and more. Each type has its own unique advantages and disadvantages, so it is important to choose the one that is best suited to your needs.

2. Capacity

Another important consideration is the capacity of the crusher. This will depend on the size of your operation and the amount of material you need to process. Make sure to choose a crusher with a capacity that is appropriate for your needs.

3. Mobility

If you need to move your crusher from one site to another, mobility is an important factor to consider. Mobile crushers are available that can be easily transported from one location to another, while stationary crushers are designed to stay in one place.

4. Maintenance

Maintenance is an important consideration when choosing a crusher. Make sure to choose a crusher that is easy to maintain and that comes with good customer support. This will help to ensure that your crusher stays in good working order and that you get the most out of your investment.

5. Cost

Finally, cost is an important consideration when choosing a crusher. Make sure to choose a crusher that fits within your budget, but also make sure that you are getting a high-quality product that will last for years to come.

In summary, when choosing a crusher, it is important to consider the type of crusher, capacity, mobility, maintenance, and cost. By taking the time to evaluate your needs and carefully consider these factors, you can choose a stone crusher that is best suited to your operation and that will help you to achieve your goals.

People alse frequently asked for-FAQ:

1. Jaw crusher vs cone crusher

2. Jaw crusher vs impact crusher

3. Jaw crusher vs roll crusher

4. Jaw crusher vs gyratory crusher

5. Jaw crusher vs hammer mill crusher

6. Difference between gyratory and cone crusher

2026-02-07

2026-02-07

86-15093113821

86-15093113821

86-15093113821

86-15093113821