Gravel and sand form the literal building blocks of our infrastructure. From concrete in skyscrapers to asphalt on highways, these aggregates are indispensable. An efficient stone gravel production line is about maximizing product quality, minimizing operational costs, and ensuring long-term reliability. Whether you are crushing hard granite or soft limestone, this guide will walk you through the essential equipment and how to configure them for maximum efficiency.

Phase 1: The Feeding System

Everything starts here. If the feed is inconsistent, the entire line suffers.

● The Equipment: Vibrating Feeder

● How it Works: It sits under the raw ore hopper and shakes the material into the primary crusher.

● Efficiency Tip: Look for a feeder with "Grizzly Bars" (gaps between steel bars). These bars allow small rocks and dirt to fall through before entering the crusher. This "pre-screening" reduces the load on your primary crusher and prevents dirt from contaminating your final product.

Phase 2: Primary Crushing

The primary crusher accepts raw, blasted rock from the quarry face and performs the first major size reduction.

● The Equipment: Jaw Crusher

● Why it’s Essential: The Jaw Crusher is the workhorse. It mimics a chewing motion to break rock by compression.

● Efficiency Configuration:

○ Don’t undersize your Jaw. It is better to have a Jaw Crusher that is slightly too big than one that is too small. If the feed opening is too small, you will waste time using hydraulic hammers to break oversized rocks at the intake.

○ Keep the setting tight enough to relieve the secondary stage, but open enough to maintain high throughput.

Phase 3: Secondary Crushing

This is where most configuration mistakes happen. The equipment you choose here depends entirely on the hardness of your stone.

Scenario A: Hard Rock (Granite, Basalt, River Stone, Iron Ore)

If your rock is abrasive and hard, you must use compression crushing.

● The Equipment: Cone Crusher (Hydraulic or Spring Or Symons type)

● Why: Impact crushers (which use blow bars) will wear out in hours on hard rock. Cone crushers use a mantle and bowl liner to crush rock against rock ("lamination crushing"). They are expensive upfront but save millions in wear parts over time.

● Configuration: A Multi-Cylinder Hydraulic Cone is the modern standard for high efficiency. It offers automated clearing if the chamber gets blocked.

Scenario B: Soft Rock (Limestone, Gypsum, Coal)

If your rock is soft and not abrasive, you can prioritize shape and lower capital cost.

● The Equipment: Impact Crusher (PF or HSI)

● Why: Impact crushers use high-speed rotors to shatter rock. They produce excellent cubical shapes (no flakes). Because the rock is soft, the blow bars last a long time.

● Configuration: For a limestone quarry, an Impact Crusher is often the only secondary stage needed.

Phase 4: Tertiary Crushing / Sand Making

With the shortage of natural river sand globally, Manufactured Sand (M-Sand) is becoming the most profitable product in the quarry.

● The Equipment: VSI Crusher (Vertical Shaft Impactor)

● How it Works: This is a "Stone-beating-Stone" machine. Rock falls into a spinning rotor and is thrown against a rock-lined anvil.

● Why you need it:

○ Shaping: It knocks the sharp edges off the gravel, making it perfectly round/cubical for high-grade concrete.

○ Sand Production: It turns pea gravel (waste rock) into valuable sand (0-5mm).

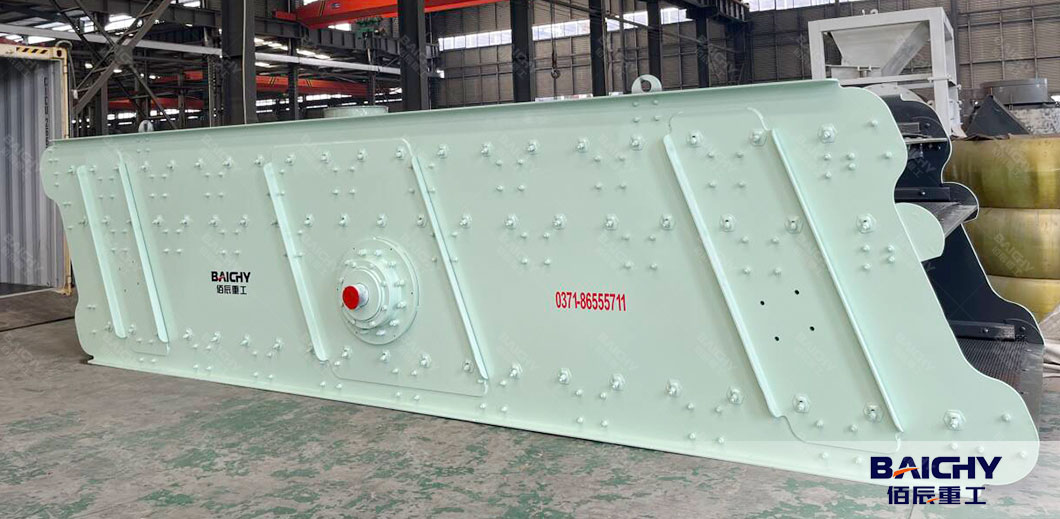

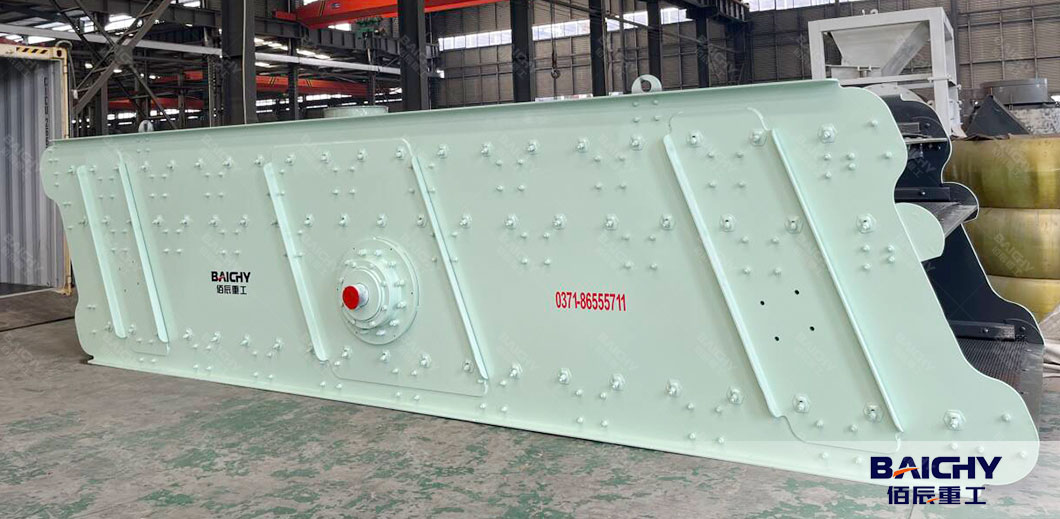

Phase 5: Screening

This is arguably the most critical phase for efficiency and profitability. Screening separates your mixed material into precise, saleable product sizes.

● The Equipment: Vibrating Screen (Circular or Linear)

● Configuration: Most plants use a multi-deck screen (e.g., 3 or 4 decks).

○ Top Deck: Catches oversize rock and sends it back to the Secondary Crusher (Closed Circuit).

○ Middle Decks: Separate the standard aggregates (e.g., 20mm, 10mm).

○ Bottom Deck: Separates the sand (0-5mm).

Phase 6: Washing (Optional but Recommended)

To produce high-quality manufactured sand (a.k.a. artificial sand or M-sand), you need a dedicated sand-making circuit.

● The Equipment: Sand Washer (Wheel Type or Screw Type)

● Why: It washes away dust, clay, and impurities from the VSI output.

● Result: Clean, high-quality sand that fetches a higher market price

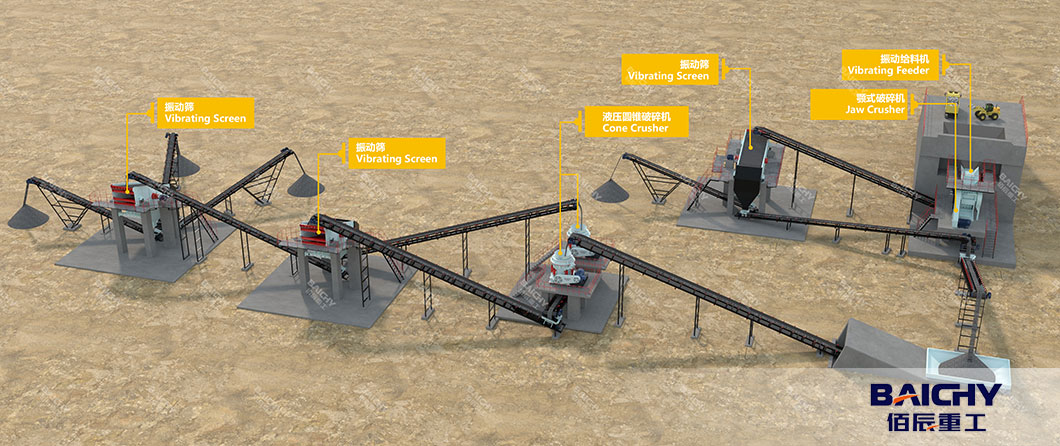

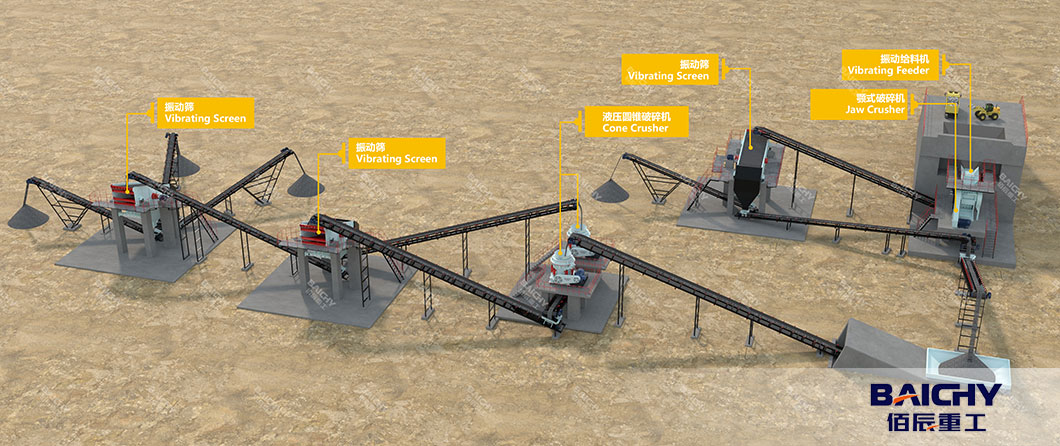

Putting It Together: Two Example Configurations

To help you visualize, here are two standard setups for a 200 Tons Per Hour (TPH) plant.

Configuration 1: The "Hard Rock" Line (Granite)

● Best for: High wear resistance, long-term low operating costs.

● Flow: Feeder →→Jaw Crusher →→ Cone Crusher →→Vibrating Screen →→ (Oversize back to Cone) →→ Finished Aggregate.

(Optional add-on: VSI Crusher after the Cone for sand making).

Configuration 2: The "Soft Rock" Line (Limestone)

● Best for: Low initial investment, excellent particle shape.

● Flow: Feeder →→ Jaw Crusher →→ Impact Crusher →→ Vibrating Screen →→ Finished Aggregate.

Conclusion: Efficiency is a Symphony, Not a Solo

Configuring an efficient gravel and sand production line is about creating a harmonious system where each component is correctly sized and sequenced for your specific material and goals. There is no universal "best" setup.

The Efficient Configuration Checklist:

Match equipment to material hardness.

● Embrace the closed-circuit design in secondary crushing.

● Invest in high-capacity, multi-deck screening for maximum product separation.

● Use a dedicated VSI and washer for premium sand production.

● Design a compact, logical conveyor layout to minimize transfer points.

● Integrate modern control systems for operational data and ease of use.

By viewing your production line as an interconnected system and making informed choices at each phase, you can build a plant that delivers maximum tons per hour, per dollar, and per kilowatt—the true measures of efficiency.

2026-01-06

2026-01-06

86-15093113821

86-15093113821

86-15093113821

86-15093113821