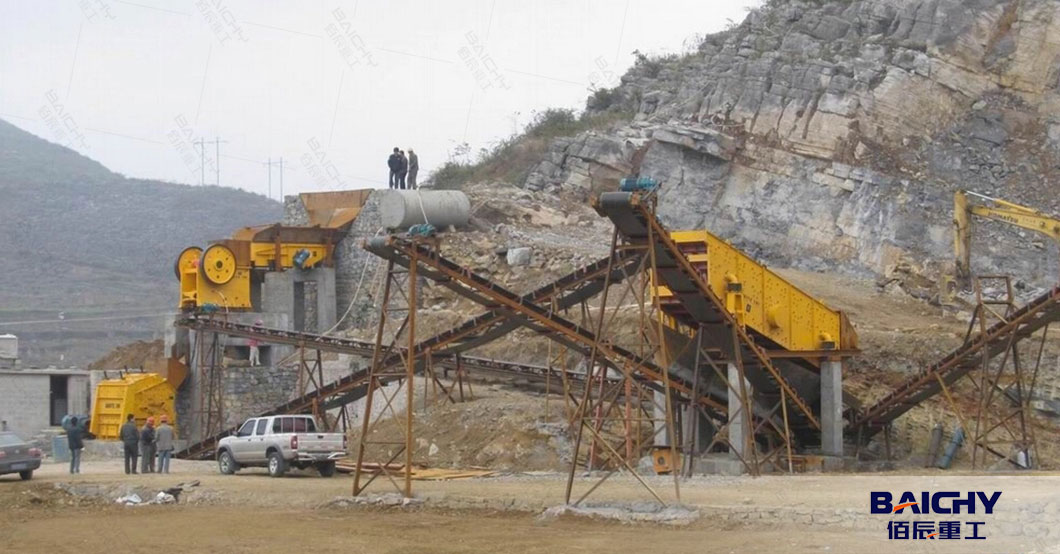

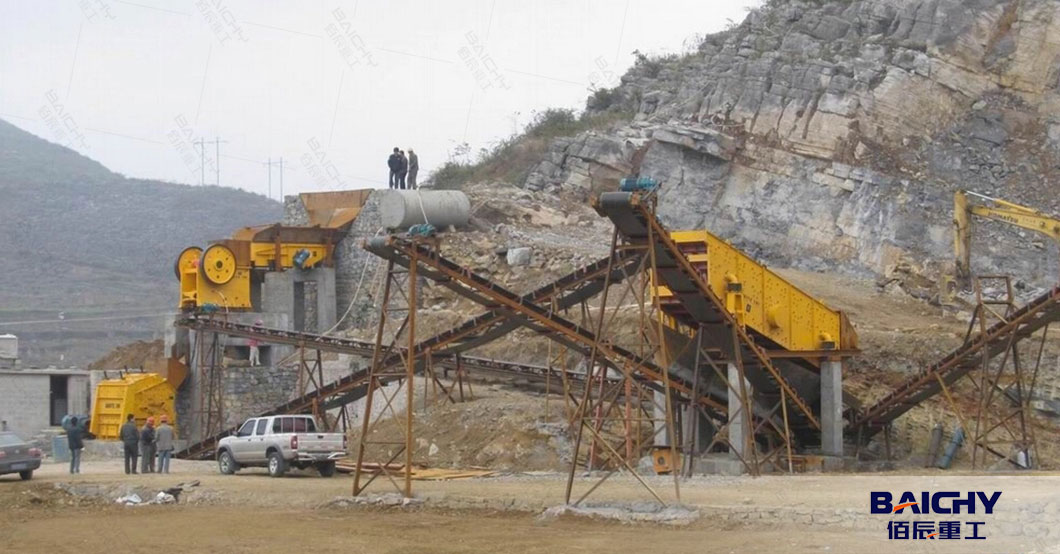

In order to make full use of mining resources and increase corporate profits, major cement companies have built sand and gravel aggregate production lines. Design plays a very critical role in designing a aggregate production line with qualified product quality, safety and environmental protection according to the characteristics of each aggregate mine. The sand and gravel aggregate production line is mainly composed of a crushing system, a screening system, a sand making system (there is no system if sand is not produced), a storage and shipping system and a dust removal system. Let's take a look at the main design points of each component system.

1. Crushing system

Crusher selection principle

The crushing system is mainly composed of coarse crushing, medium crushing and fine crushing (shaping). The selection of equipment at each stage is mainly determined by the crushing work index, abrasive index, maximum feed particle size and product quality requirements of the ore.

The typical processes of the crushing system are: jaw crusher + impact crusher system, jaw crusher + cone crusher system, jaw crusher + impact crusher + vertical shaft crusher system and jaw crusher + cone crusher + cone crusher system. The selection of the crushing system should be determined based on the material characteristics, product particle shape and market demand.

(1) Jaw crusher + impact crusher system

This system consists of a jaw crusher, an impact crusher and a screening system.

The advantages of this system are: the system has a large number of capacity specifications, can be scaled up, and has a wide range of applications; the product variety ratio is easy to adjust; and it is suitable for materials with medium abrasiveness index.

The disadvantages are: high energy consumption per unit product; poor adaptability to high abrasiveness index ores, medium product particle shape, and medium acquisition rate of coarse-grained aggregates; the crusher requires a large dust collection air volume; and the consumption of wear parts is higher than that of cone crushers.

(2) Jaw crusher + cone crusher system

This system consists of a jaw crusher, a cone crusher and a screening system.

The advantages of this system are: the product variety ratio is easy to adjust; it is suitable for materials with high abrasiveness index; the product has good particle shape, small amount of fine powder, and high rate of coarse aggregate; the dust collection air volume required by the crusher is small; the unit energy consumption is low; and the consumption of wear parts is low.

Disadvantages: cone crushers have fewer specifications. When the system capacity requirements are large, three-stage crushing or more crushers are required. At this time, the process is complicated and the project investment is high; its scope of use is relatively narrow compared to the impact crusher.

(3) Jaw crusher + impact crusher + vertical shaft crusher system

This system consists of a jaw crusher, an impact crusher, a vertical shaft crusher and a screening system. Its process is basically the same as that of the jaw crusher + impact crusher system, except that a vertical shaft crusher is added to shape the aggregate to meet the needs of customers for high-quality aggregates. In addition to the advantages and disadvantages of the jaw crusher + impact crusher system, this system also has the following characteristics: it can provide multiple quality aggregates to meet the needs of different customers, and the vertical shaft crusher produces more fine powder, which can also take into account the production of machine-made sand; but the process is complicated, the project investment is high; and the unit product energy consumption is high.

(4) Jaw crusher + cone crusher + cone crusher system

This system consists of a jaw crusher, a cone crusher, a cone crusher and a screening system. Its process is basically the same as that of the jaw crusher + cone crusher system, except that a first-level cone crusher is added. In addition to the advantages and disadvantages of the jaw crusher + cone crusher system, this system also has some characteristics: it can meet the requirements of a larger system output capacity; but the process is complicated and the project investment is high.

Buffer pile or buffer bin setting

A semi-finished product pile is designed between the primary crushing and the secondary and fine crushing of the aggregate production line. The function of this semi-finished product pile is to balance the overall system capacity of the aggregate production line. The specification selection of the secondary and fine crushing crushers does not need to consider the fluctuation coefficient of the primary crusher; if the primary crushing workshop is under maintenance, the downstream aggregate processing workshop can continue to produce; in addition, for safety reasons, most mines only mine in the day shift, so the downstream aggregate processing workshop can still produce in two shifts to flexibly meet market demand, and the number of equipment in the downstream aggregate processing workshop can be reduced by half or equipment with small production capacity can be selected to match the upstream (because the semi-finished product pile can flexibly adjust the system capacity), which can reduce system investment accordingly.

2. Screening system

The main design points of the screening system are:

Reasonably select the area of the screen;

The chute between the upstream conveying equipment and the vibrating screen should be designed correctly to ensure that the material can be spread on the entire screen surface;

Reasonably configure the specifications of the dust collector to ensure that environmental protection requirements are met;

The chute between the vibrating screen and the downstream conveying equipment should consider anti-wear and anti-noise.

3. Sand making system

The sand making system is mainly composed of a shaping sand making machine, a vibrating grading screen, a grading adjustment machine, and an air screen. Its main design points are: the closer the particle size of the raw material entering the sand making machine is to the product, the higher the sand making efficiency is. Therefore, try to use raw materials with smaller particle sizes during production, rather than using oversized raw materials. This will not only reduce the sand making efficiency, but also accelerate the loss of equipment; the moisture content of the raw material entering the air screen cannot exceed 2%, otherwise it will affect the separation efficiency of the air screen. For areas with more rain, rain protection measures should be considered in the design.

4. Storage and Shipping System

The finished product storage generally adopts closed steel warehouse (or concrete warehouse) and steel structure greenhouse. The shipping system corresponding to the warehouse is the automatic loading machine for cars, and the shipping system corresponding to the steel structure greenhouse is the forklift loading. Their advantages and disadvantages are: the investment per unit storage of the warehouse is higher than that of the steel structure greenhouse, but it has less dust and high automatic loading efficiency; the investment per unit storage of the steel structure greenhouse is low, but its working environment is poor and the loading efficiency is low. In areas with strict environmental protection requirements, closed steel warehouses (or concrete warehouses) are preferred, which is more conducive to passing environmental protection acceptance.

5. Dust removal system

The dust removal system consists of two parts: water spray dust reduction and bag dust collector. The function of water spray is to generate less dust, and the function of bag dust collector is to collect the generated dust.

In the aggregate production line, a water spray device is generally set at the head funnel of the belt conveyor at the unloading bin and each transfer station. If the finished product storage adopts a steel structure greenhouse, a water spray device is also set. The design points of the water spray device are: the nozzle position and number are reasonably designed, the water volume can be adjusted, and the water pressure is guaranteed. Otherwise, the dust reduction effect is not obvious and it is easy to block the mesh of the vibrating screen and affect production.

The design points of the bag dust collector are: the specifications, quantity and end duct of the bag dust collector should be reasonably designed, and the dust collection ash should be stored in a separate storage tank and not returned to the production line to avoid secondary dust downstream.

In addition, minimizing the drop of each material chute in the design can not only reduce a certain construction cost, but also reduce dust generation.

The system process of the sand and gravel aggregate production line should be determined based on the specific environment, material characteristics, product particle shape and market demand. When designing, the designer should consider the key points of each process according to the characteristics of the aggregate mine, so as to design a production line with low construction investment, low operating cost, high economic benefit and environmental friendliness.

2026-01-06

2026-01-06

86-15093113821

86-15093113821

86-15093113821

86-15093113821