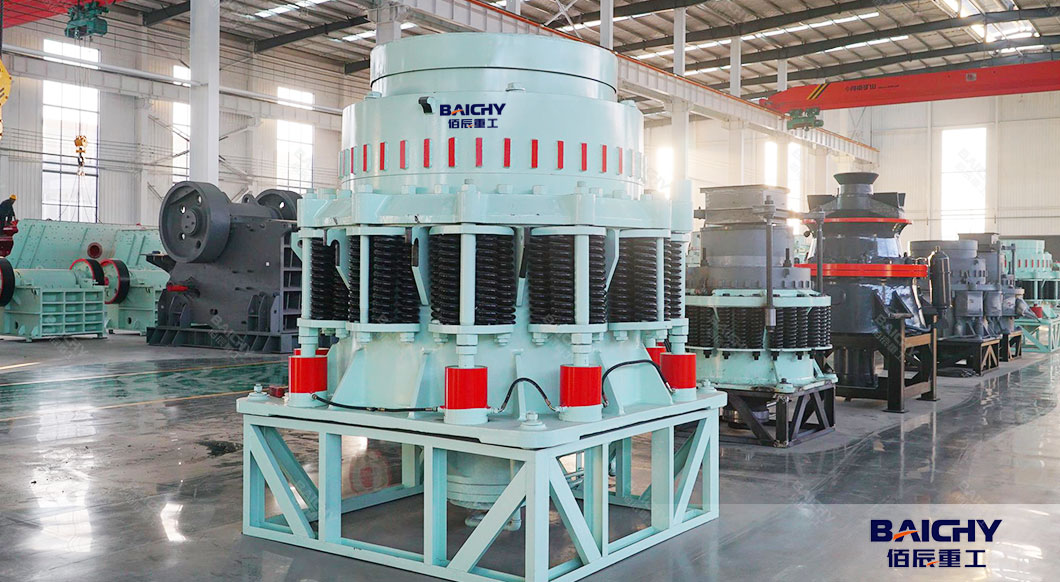

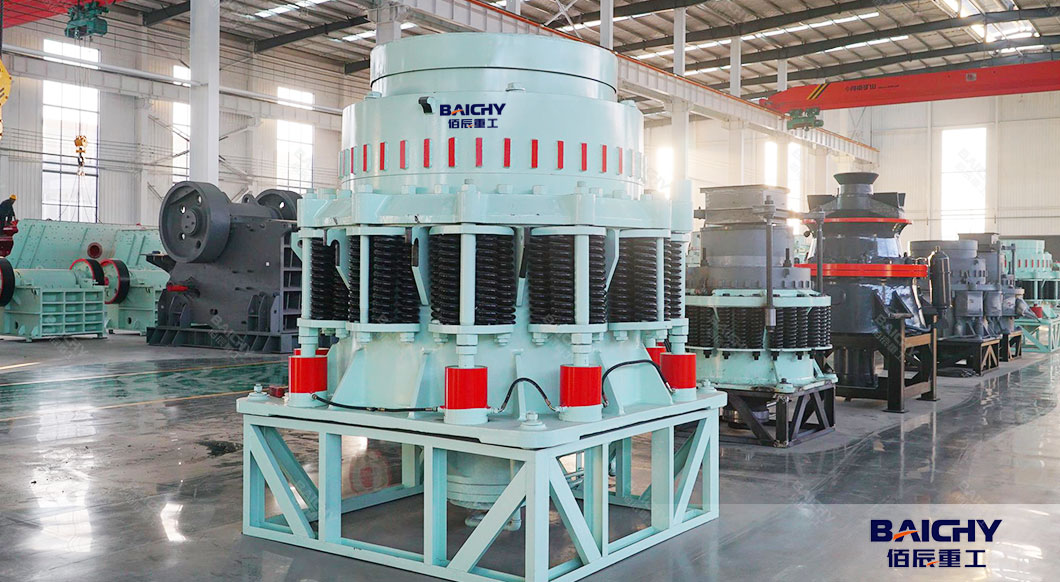

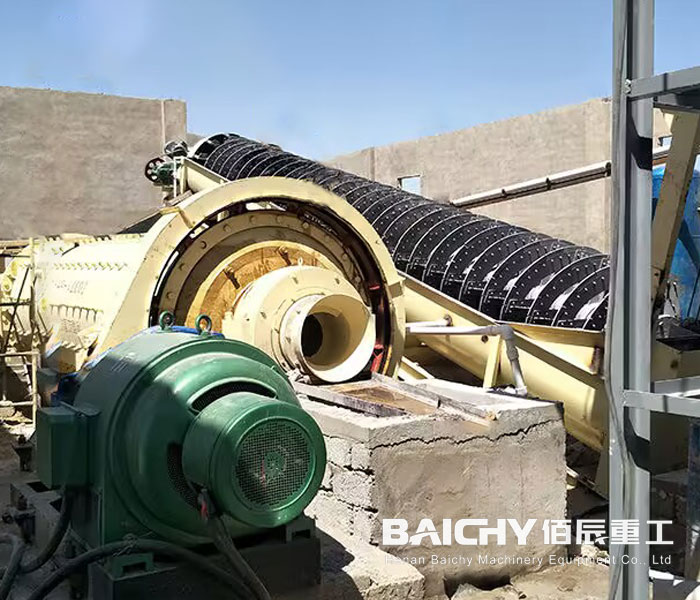

If you’re in the mining, quarrying, or aggregate industry, you know that fine crushing is make-or-break for product quality and project profitability. When it comes to reliable, efficient fine crushing, the Symons 3ft Short Head Cone Crusher stands out as a tried-and-tested workhorse. Designed for secondary or tertiary crushing of hard and abrasive materials—from granite and limestone to iron ore and basalt—this crusher delivers consistent, high-quality fine aggregates (typically ¼ inch to ½ inch) that meet strict industry standards. One of our customer knows the symons cone crusher well, he chose it directly as his secondary crushing machine in the 80tph granite crusher plant. Now this symons 3ft short-head cone crusher is loading and shpping to Indonesia. Why customer chose symons 3ft short-head cone crusher machine? Let exlpore it as below.

What Is a Symons 3ft Short Head Cone Crusher?

1.Symons: This refers to the Spring Cone design principle. It uses a bronze bushing system and a circle of heavy-duty springs for protection. It is widely considered the most reliable mechanical design in crushing history.

2.3ft (3 Foot): This is the diameter of the cone head (mantle) at the bottom.It is about 3 feet, or approximately 900mm. It compact enough for portable plants but powerful enough to process 20 to 90 tons per hour (depending on the setting).

3. Short Head: This is the most critical part.

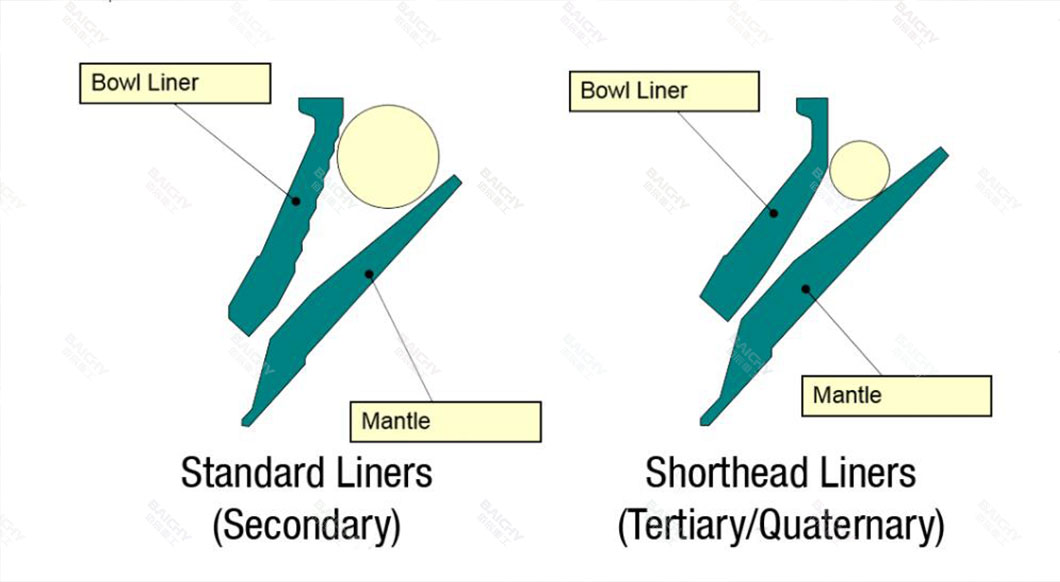

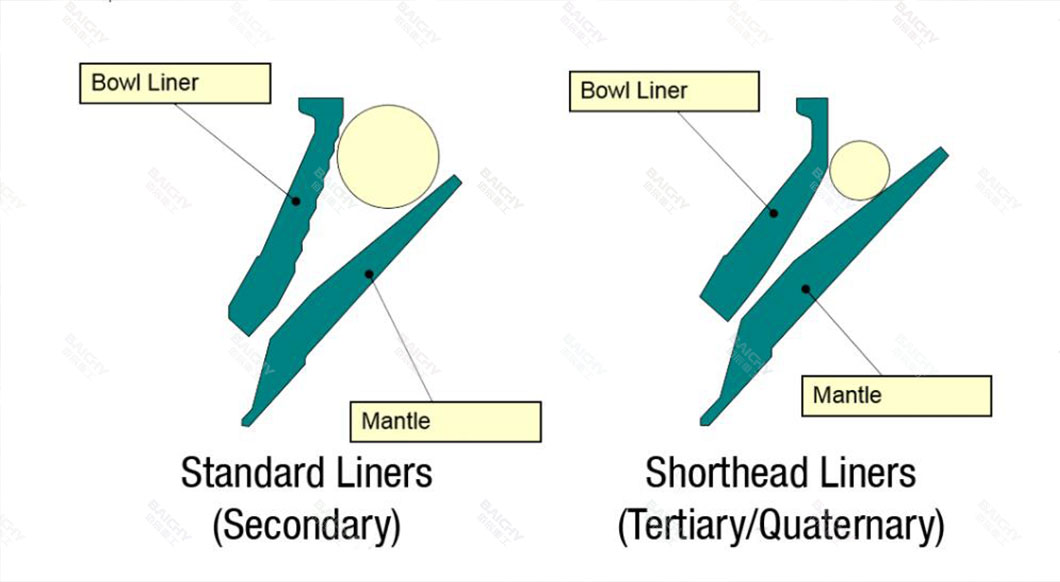

● Standard Cone: Used for Secondary crushing (coarse output).

● Short Head Cone: Used for Tertiary crushing (fine output).

The "Short Head" Difference:

The Short Head cone has a much steeper crushing angle and a longer "parallel zone" (the squeezing area) compared to the Standard model. This design is engineered specifically to take small feed (typically usually under 60mm) and crush it into very fine product (minus 6mm to 19mm).

● If you want to make sand or 1/2-inch gravel, you buy a Short Head.

Why the Symons 3ft Short Head dominates the Market

In an era of hydraulic "push-button" crushers, why do buyers still like this mechanical crusher?

1. Unmatched Product Shape (Cubicity)

The Symons crushing principle is famous for producing "cubical" rock. Because the Short Head features a long parallel zone at the discharge, the rock is crushed multiple times before it exits.

● The Result: You get fewer "flakes" and needles. If you are selling to concrete plants or asphalt stations that have strict flakiness index requirements, this machine makes your product easier to sell.

2. The "Spring" Safety Net

The circle of springs around the top of the crusher isn't just decoration. It is a fail-safe system. If "Tramp Iron" (a piece of uncrushable steel, like a loader tooth) enters the chamber:

● The springs stretch, allowing the adjustment ring to lift.

● The discharge opening widens momentarily.

● The steel passes through without breaking the main shaft.

● The springs snap the ring back down, and crushing continues.

● Simple Translation: It protects your investment automatically.

3. Simplicity = Uptime

Modern high-pressure hydraulic crushers are fantastic—until a sensor fails, a PLC board fries, or a complex valve gets stuck. When that happens, you often need a specialized technician with a laptop to fix it.

The Symons 3ft cone crusher is mechanical. It runs on gears, bushings, and oil.

● Benefit: Any mechanic with a wrench and basic knowledge can fix it. In remote mining sites (like in parts of Africa, South America, or Southeast Asia), this repairability is worth its weight in gold.

4. High Resale Value

Because this cone crusher machine is the industry standard, parts are available globally from hundreds of suppliers. You are never held hostage by one manufacturer. Furthermore, a well-maintained Symons 3ft holds its value incredibly well. It is a liquid asset.

User’s Guide: Tips for Maximum Efficiency

If you already own one, or are about to buy one, here are three tips to get the most TPH (Tons Per Hour) out of your Symons 3ft Short Head.

1. Choke Feed It!

Cone crushers are designed to operate with a full cavity.

Do not trickle feed the rock. You want a pile of rock sitting on top of the feed opening. The weight of the rock above forces the material down into the crushing zone.

Why? Choke feeding ensures "inter-particle crushing" (rock crushing rock), which improves shape and wears the liners evenly.

2. Watch the "Closed Side Setting" (CSS)

Since you are using a Short Head, you are likely chasing a specific product size. Check your CSS regularly.

● Tip: As the mantle and bowl liner wear down, your setting gets bigger, and your product gets coarser. Adjust the bowl down regularly to maintain your spec.

3. Keep the Oil Clean

The Symons 3ft uses Bronze Bushings. These are incredibly durable if they are lubricated. They rely on a film of clean, cool oil to survive.

● Maintenance: Check your oil filter and temperature daily. If you keep the oil clean, the main shaft and bushings can last for decades.

In the mining industry, we often get distracted by the shiny and new. But when you have a contract to fulfill and a deadline to meet, you don't need shiny—you need proven. The Symons 3ft Short Head Cone Crusher has survived for decades because it does one thing perfectly: it turns gravel into profit.

Are you ready to optimize your tertiary crushing circuit? Whether you are setting up a new plant or replacing an old unit, the 3ft Short Head is a choice you won't regret. Contact us to get professional solution and price list, welcome to visit our factory too.

2026-01-04

2026-01-04

86-15093113821

86-15093113821

86-15093113821

86-15093113821