Winter brings unique challenges to construction and mining operations, especially for mobile stone crusher plants. Low temperatures, freezing precipitation, and harsh conditions often lead to frustrating issues like difficult startup, reduced efficiency, and increased equipment wear. However, with the right mobile stone crusher plant designed for winter performance, these pain points can be eliminated. This article dives into the common cold-weather problems and solution for right operations in winter.

Common Winter Operation Pain Points of Mobile Stone Crusher Plants

1. Difficult Startup in Low Temperatures

One of the most annoying issues in winter is the failure to start the mobile stone crusher plant smoothly. When temperatures drop below 0°C (32°F), engine oil thickens, battery performance declines sharply, and fuel may gel. Traditional crusher plants often require hours of preheating or even external heating equipment, delaying project schedules and increasing labor costs and tight deadlines.

2. Reduced Crushing Efficiency

Cold weather directly impacts the crushing efficiency of mobile crushing plants. Low temperatures make stone materials brittle and increase friction between moving parts. This dual effect causes the crusher to consume more energy. Moreover, frozen aggregates can stick to the crushing chamber, leading to blockages that require manual cleaning. This is another time-consuming and labor-intensive task that disrupts continuous operation.

3. Increased Risk of Equipment Damage

Winter conditions accelerate wear and tear on mobile stone crusher plants. Freezing water can seep into gaps and cracks, expanding when frozen to cause component deformation. Hydraulic systems, a core part of mobile crushers, are particularly vulnerable: cold temperatures reduce hydraulic fluid viscosity, leading to leaks, poor pressure control, and even pump failure. Additionally, rubber parts like belts and hoses become stiff and prone to cracking, resulting in unexpected downtime and high maintenance costs.

4. Poor Adaptability to Harsh Weather

Snow, ice, and strong winds further complicate winter operations. Snow accumulation on the machine can block vents and coolers, causing overheating.

Why High-Quality Mobile Stone Crusher Plants Performs Well in Winter

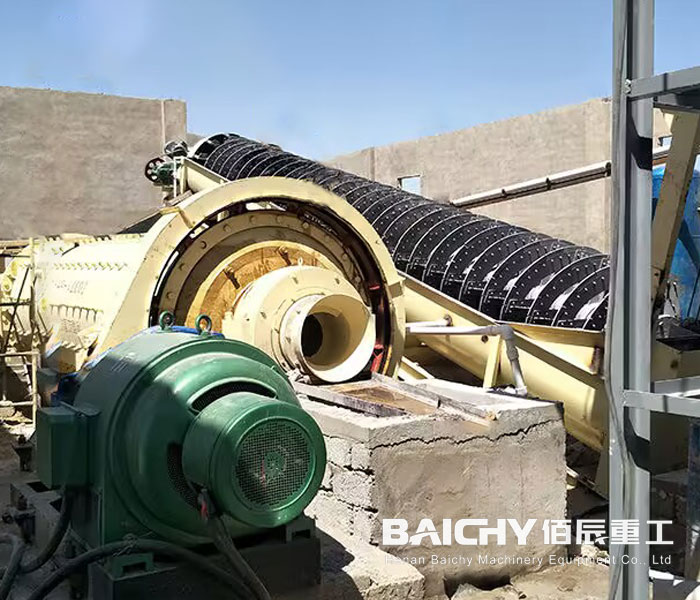

To solve these pain points, Baichy mobile stone crusher plants are engineered with winter-specific features that ensure reliable performance even in extreme cold.

1. Efficient Cold-Start System

Baichy mobile crusher plants are equipped with high-performance batteries and engine preheaters, enabling them to start quickly even at temperatures as low as -30°C (-22°F). The preheating system can preheat the engine oil and coolant in advance, eliminating the need for long waiting periods or external heating. Additionally, low-temperature-resistant fuel filters prevent fuel from gelling, ensuring a stable fuel supply and thus guaranteeing continuous operation of the equipment.

2. Optimized Crushing Mechanism

The crushing chamber is designed with anti-sticking liners that prevent frozen aggregates from adhering, reducing blockages and maintaining high throughput. The transmission system uses low-temperature lubricants that retain their viscosity in cold weather, minimizing friction and energy consumption. With these optimizations, the mobile crusher plant maintains its rated efficiency even in winter.

3. Durable and Cold-Resistant Components

All critical components, from hydraulic systems to rubber parts, are made of cold-resistant materials. Hydraulic fluids with low freezing points prevent leaks and ensure smooth operation, while reinforced rubber belts and hoses resist cracking in low temperatures. The machine’s structure is sealed to prevent water ingress, and anti-freeze protection for water tanks and pipelines avoids freezing damage. These design choices significantly reduce maintenance needs and extend the equipment’s service life in winter.

4. Strong Weather Adaptability

Protective covers for vents and coolers prevent snow accumulation, while windproof designs reduce the impact of strong winds.

Mobile crushers can operate normally in cold seasons. By carrying out proper maintenance and using suitable lubricating oil, you can keep the crushing mechanism in good condition, thereby increasing output and operating time. Welcome to contact us to get more information about mobile mobile stone crusher plant works in winter.

People Also Frequently Asked For - FAQ

Q1: Will the machine work slower in winter?

A: It might be slightly slower because frozen stone is harder. However, because the machine has heaters, you save time on "warming up" in the morning. This keeps your daily production high.

Q2: Do I need to change the oil for winter?

A: Yes. You must use "winter-grade" oil and grease. Normal oil becomes too thick in the cold, which can damage the engine. Thinner oil protects the machine better.

Q3: How do I stop conveyor belts from freezing?

A: Ice can make belts slip. To stop this, always clean the belts. Also, run the conveyor empty for 5 minutes before you turn it off. This removes wet snow before it freezes.

Q4: What is the most important rule for stopping the machine?

A: Never stop the engine while there is still stone inside. If wet stone freezes inside the crusher overnight, it turns into a solid block. This will break the machine when you start it the next day. Always empty the machine first.

2026-01-04

2026-01-04

86-15093113821

86-15093113821

86-15093113821

86-15093113821