In the mining, construction, and aggregate processing industries, efficiency, durability, and performance are important factors when selecting crushing equipment. The High Efficiency Symons Cone Crusher CS110 is a nice solution, engineered to deliver exceptional crushing results while optimizing operational costs. Recently, we delivered one set symons cone crusher to Philippines. Why this cone crusher ramains a bestseller and how it can boost your plant's profitability. Let's study as below.

1. Overview of High Efficiency Symons Cone Crusher CS110

The Symons Cone Crusher is a modern optimization of the traditional Symons spring cone crusher. It is a high-performance secondary and tertiary crushing machine designed for processing various materials, including granite, basalt, limestone, quartz, and iron ore.

● Model Code: CS110 (often referred to as the 4 Ft Standard or Short Head depending on cavity).

● Cone Diameter: 1200 mm (4 feet)

● Motor Power: 110 kW

● Capacity: 45 – 200 Tons Per Hour (depending on cavity and feed).

2. Key Advantages: Why Choose the CS110?

Why do plant managers continue to choose the Symons CS110? The answer lies in its distinct benefits:

1.Superior Crushing Efficiency

The Symons cone crusher CS110 adopts an optimized crushing chamber (standard, medium, or short head for different product sizes) with a steep cavity angle and large stroke. This design increases the contact area between materials and crushing cones, enabling faster and more thorough crushing.

2. Durable & Reliable Construction

Durability is a hallmark of the Symons CS110. The machine features a heavy-duty welded frame with high rigidity, minimizing vibration during operation and extending service life. Critical components such as the cone liner, mantle, and eccentric bushing are made of high manganese steel or alloy steel, ensuring resistance to wear and impact. Additionally, the advanced hydraulic system provides overload protection—if uncrushable materials enter the chamber, the system automatically adjusts the discharge gap to prevent damage, reducing downtime and maintenance costs.

3. Flexible Adjustment & Uniform Product Size

The cone crusher CS110 offers precise control over the final product size through its hydraulic adjustment system. Operators can easily adjust the discharge gap within a wide range (10-50mm) to meet specific requirements, from coarse aggregates for road construction to fine particles for concrete production. The crushing process produces a uniform product with a cubic shape and low needle-like content, which is highly sought after in high-quality aggregate markets. This flexibility makes the CS110 suitable for multiple applications, enhancing its versatility for different projects.

4. Easy Maintenance & Low Operating Costs

Designed with user-friendliness in mind, the CS110 simplifies maintenance procedures. The hydraulic system allows for quick replacement of wear parts (e.g., liners and mantles) without disassembling the entire machine, saving time and labor. The centralized lubrication system ensures all moving parts are adequately lubricated, reducing friction and wear. Moreover, the machine’s high reliability and long component life mean fewer replacements and lower operating costs over its lifespan, delivering a strong return on investment (ROI) for users.

Real-World Application Cases of Symons CS110

The High Efficiency Symons Cone Crusher CS110 has been widely adopted in various industries globally

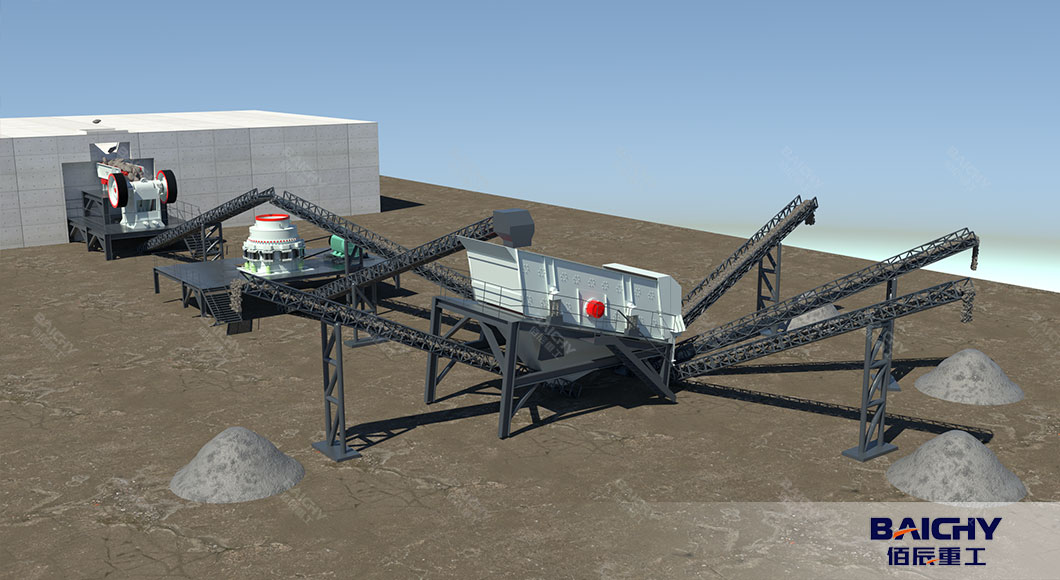

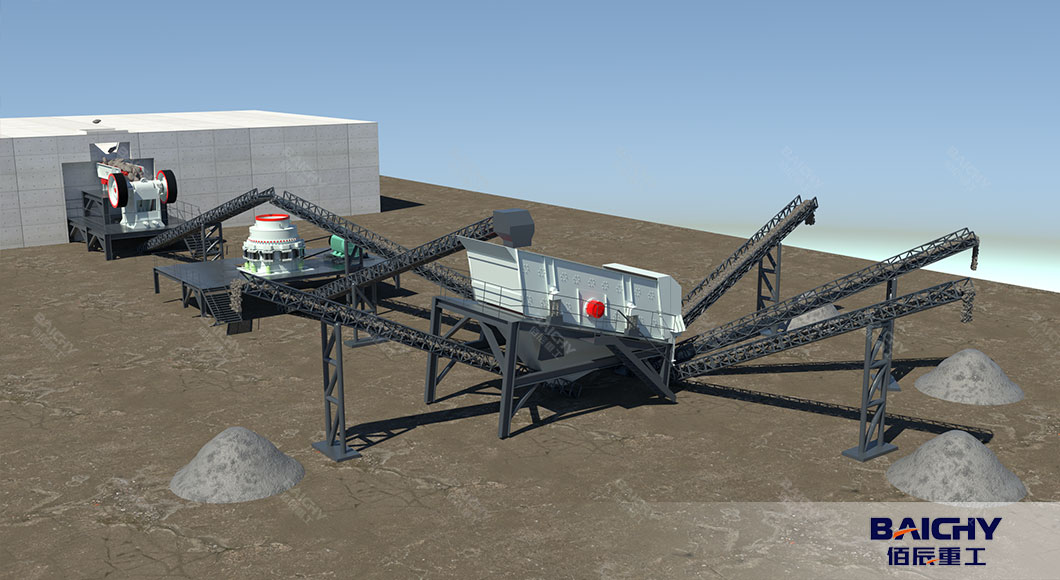

● Hard Rock Aggregate Plant (Philippines)

● Material: River Stone (Basalt/Andesite mix).

● Challenge: The customer previously used an Impact Crusher for secondary crushing, but the high silica content caused blow bars to wear out every 3 days. Operating costs were destroying profit margins.

● Solution: They upgraded to a CS110 Symons Cone Crusher (Standard Coarse Cavity).

● Result:

○ Wear Life: Mantle and bowl liners lasted over 2 months, compared to 3 days for impact bars.

○ Capacity: Consistent output of 160 TPH.

○ ROI: The reduction in wear parts cost paid for the machine in just 8 months.

If you’re in search of a high-efficiency cone crusher, contact our team today to learn more about how this machine can meet your specific crushing needs.

People Also Frequently Asked For - FAQ

Q1: What is the main difference between the CS110 Standard and CS110 Short Head models?

A: The difference lies in the cavity shape and application.

● CS110 Standard: Has a wider feed opening and coarser liners. It is used for Secondary Crushing (taking the output directly from a Jaw Crusher).

● CS110 Short Head: Has a steeper crushing angle and smaller feed opening. It is used for Tertiary (Fine) Crushing to produce small aggregate or sand.

Q2: Can the CS110 handle extremely hard and abrasive rock like Granite?

A: Yes. The CS110 is specifically designed for hard rock. The CS cone crusher uses high-manganese steel mantles and bowl liners to crush via compression. This makes it the most economical choice for processing abrasive materials like Granite, Basalt, and Iron Ore.

Q3: How does the overload protection system work?

A: The CS110 features a Spring Safety System. If a piece of non-crushable material (such as a steel excavator tooth or "tramp iron") enters the crushing chamber, the springs allow the upper adjustment ring to lift up momentarily. This expands the discharge opening, letting the metal pass through without damaging the main shaft or bearings, after which the machine automatically resets.

Q4: What is the maximum feed size for the CS110?

A: It depends on the cavity configuration:

● For the Standard (Coarse) cavity, it can accept feed up to approximately 180mm - 200mm.

● For the Short Head (Fine) cavity, the maximum feed size is typically around 60mm - 90mm.

Always consult the specific liner profile chart before feeding, as "Extra Coarse" or "Fine" liners will change these limits.

2026-01-04

2026-01-04

86-15093113821

86-15093113821

86-15093113821

86-15093113821