Mobile stone crusher plants have become a cornerstone in the construction, mining, and aggregate industries due to their versatility and on-site processing capabilities. However, their price tags often leave buyers wondering: why do these machines come with such a significant cost? The answer lies in a combination of advanced engineering, specialized components, mobility infrastructure, and high manufacturing standards. Below is a detailed breakdown of the key factors contributing to their expensive nature:

1. Sophisticated Mobile Chassis and Mobility Systems

The most distinct feature of a mobile crusher is its ability to move freely across job sites, eliminating the need for fixed infrastructure. This mobility requires:

- Heavy-Duty Chassis Construction: Mobile crushers are built on robust steel frames or tracked systems (similar to excavators) to support the weight of the crushing equipment and withstand rough terrain. Tracked models (track mobile crushers) often cost more than wheeled versions due to their durability in off-road conditions.

- Powerful Propulsion Systems: Wheeled models may require truck-mounted chassis with diesel engines or hydraulic drives, while tracked models use hydraulic motors for traction. These systems must be engineered to handle the machine’s weight (often 20-100+ tons) and ensure stable movement.

- Hydraulic Folding Mechanisms: Many mobile crushers feature hydraulic systems that allow the crushing unit to fold or retract for transport, reducing the machine’s footprint. These mechanisms require precision engineering and high-quality hydraulics, adding to costs.

2. High-Performance Crushing Equipment and Components

The crushing mechanism itself is a major cost driver, as it must handle tough materials like granite, basalt, or concrete:

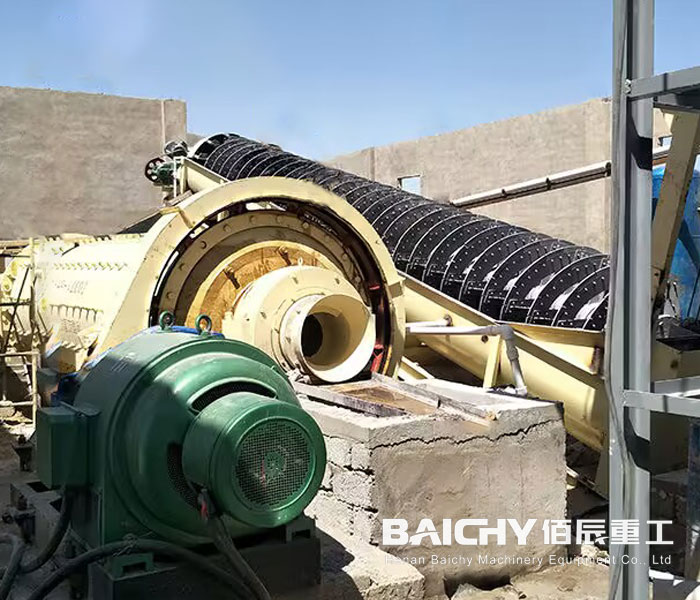

- Crusher Type and Quality: Mobile plants often integrate jaw crushers, cone crushers, impact crushers, or vertical shaft impactors (VSIs). Premium crushers use wear-resistant materials like manganese steel or chromium alloy for liners and hammers, which are expensive but essential for longevity.

- Large Processing Capacity: High-output mobile crushers (e.g., 200-500 TPH) require larger rotors, stronger bearings, and more powerful motors. For example, a 300 TPH mobile impact crusher may need a 300-500 HP engine, which alone accounts for a significant portion of the cost.

- Advanced Screening and Feeding Systems: Many mobile plants include integrated vibrating screens, feeder hoppers, and conveyor belts to streamline the crushing process. These components must be synchronized with the crusher for efficient operation, requiring precision design.

3. Engineered for Durability and Heavy-Duty Operation

Mobile crushers operate in harsh environments, so their construction prioritizes longevity over cost-cutting:

- Heavy-Gauge Steel and Welding: The frame and components are made from thick, high-strength steel to resist cracking under continuous vibration and impact. Welding processes must meet strict standards to ensure structural integrity.

- Abrasion-Resistant Materials: Inner linings of the crusher chamber, conveyor belts, and screen meshes are often made from wear-resistant alloys or polyurethane, which are more expensive than standard materials but reduce maintenance costs over time.

- Redundancy and Safety Features: Mobile plants include overload protection systems, emergency stop mechanisms, and dust suppression systems to comply with safety regulations, adding to manufacturing costs.

4. Complex Engineering and Research & Development (R&D)

Designing a mobile crusher involves significant R&D to balance mobility, performance, and reliability:

- Customized Engineering: Each mobile plant is often tailored to specific applications (e.g., quarrying, recycling, or road construction), requiring custom layouts and component integration. This customization increases design time and costs.

- Testing and Certification: Manufacturers must invest in testing mobile crushers for stability, load capacity, and compliance with international standards (e.g., CE, OSHA). These tests ensure the machine can operate safely in various conditions.

- Innovation in Energy Efficiency: Modern mobile crushers may incorporate hybrid power systems (diesel-electric) or electric motors to reduce emissions, which require advanced engineering and higher upfront costs.

5. Transportation, Installation, and After-Sales Support

The total cost of a mobile crusher isn’t just the machine itself—additional services contribute to the final price:

- Transportation Logistics: Shipping a large mobile crusher (which may requiredisassemble into sections for transport) involves specialized trucks, permits, and insurance, especially for international buyers.

- On-Site Installation and Commissioning: Manufacturers often provide technicians to set up the machine, calibrate components, and train operators, which are included in the purchase price.

- Warranty and Maintenance Packages: Premium mobile crushers typically come with extended warranties and service contracts, covering parts replacement and technical support. These long-term commitments add to the initial cost but provide peace of mind for buyers.

Conclusion: The Price Reflects Value and Versatility

Mobile stone crusher plants are expensive because they embody a blend of engineering excellence, heavy-duty construction, and on-site mobility—a combination that addresses the unique challenges of modern mining and construction projects. While the initial investment is steep, the ability to crush materials directly at the source, coupled with minimal infrastructure requirements, makes them a strategic asset for companies seeking efficiency and flexibility. For buyers, the key is to evaluate the total cost of ownership (including fuel, maintenance, and productivity gains) rather than focusing solely on the purchase price. In most cases, the long-term value of a mobile crusher far exceeds its upfront cost, making it a worthwhile investment for large-scale operations.

2026-01-06

2026-01-06

86-15093113821

86-15093113821

86-15093113821

86-15093113821