Look around you. The roads you drive on, the buildings you work in, the homes you live in—they all share a common, hidden foundation: aggregates. Sand, gravel, and crushed stone are the unsung heroes of our constructed world, forming the backbone of concrete, asphalt, and countless other composite materials. But these materials don't come out of the ground ready to use. Transforming raw, quarried rock into the precisely sized, clean aggregate that industry demands is a complex dance of powerful machinery. This guide breaks down the essential equipment in an aggregate processing plant, making it simple to understand how the bedrock beneath our feet becomes the bedrock of our infrastructure.

The Core Aggregates Production Process: Crushing, Screening, and Conveying

At its heart, aggregate processing is a three-step cycle:

● Crushing: Breaking down large rocks into smaller pieces.

● Screening: Sorting those pieces into specific size groups.

● Conveying: Moving material seamlessly from one stage to the next.

This cycle often repeats, with material being crushed and screened multiple times to achieve the desired product mix. Supporting equipment like feeders, washers, and classifiers fine-tunes this process for quality and efficiency.

The Aggregates Equipment Lineup: Your Plant's Key Players

1. Crushers: The Primary Reduction Force

Crushers are the muscle of the operation, using immense force to reduce the size of quarried rock. They are deployed in stages:

● Jaw Crushers: The first contact. These are primary crushers designed to handle the largest, hardest rocks straight from the quarry face. They function like a giant nutcracker, using a back-and-forth motion of a rigid plate to compress and break material.

● Gyratory Crushers: Another type of primary crusher, often used for very high-capacity operations. They use a conical head with an eccentric motion to crush rock.

● Cone Crushers: The workhorses of secondary and tertiary (fine) crushing. After the initial break by the jaw crusher, cone crushers further refine the material by compressing it between a rotating mantle and a stationary concave liner. They are excellent for producing well-shaped, cubical aggregate.

● Impact Crushers: These crushers (either Horizontal-Shaft/HSI or Vertical-Shaft/VSI) use high-speed impact from hammers or throw the rock against anvils to break it. They are fantastic for producing a uniform, shaped product and are often used for softer rock like limestone or for recycling construction debris.

2. Screens: The Sorting Masters

After crushing, a mix of different-sized particles remains. Screens are the quality control experts that sort this mix into saleable products.

● Vibrating Screens: The most common type. These multi-deck screens use a rapid vibrating motion to stratify material, allowing smaller particles to fall through specific mesh sizes while larger ones travel across the top to the next crushing stage or a different product pile. They can sort material into several sizes simultaneously.

3. Conveyors: The Circulatory System

A network of belt conveyors is the lifeline of any efficient plant. They automatically and reliably transport material from the quarry to the primary crusher, between crushing and screening stages, and out to final stockpiles. Without a robust conveying system, the entire operation grinds to a halt.

4. Essential Supporting Equipment

● Feeders: Regulate the flow of material into crushers and screens. By providing a consistent, controlled feed, they prevent blockages and ensure the downstream equipment runs at peak efficiency.

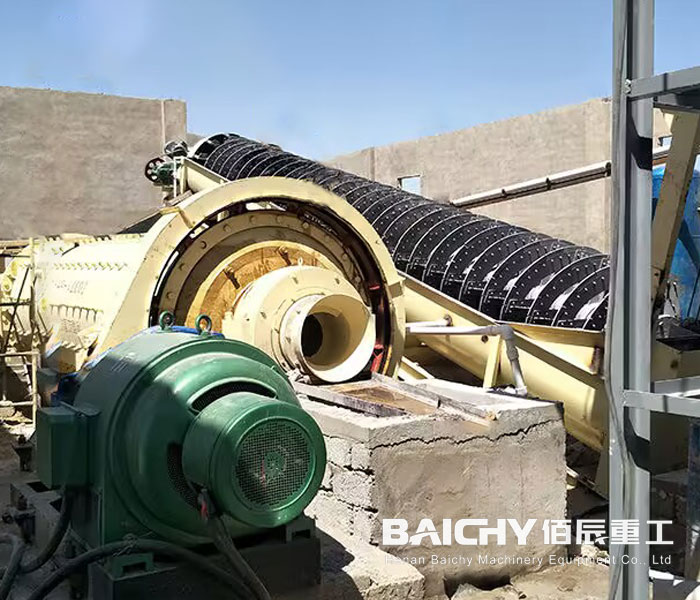

● Washing Plants and Classifiers: Not all aggregate is clean. Dirt, clay, and silt can contaminate the final product. Wash plants, which may include log washers, scrubbers, and sand screws, clean the aggregate. Classifiers and cyclones (like Cavex® hydrocyclones) use water and centrifugal force to separate fine particles and ensure a precise final product grade.

● Stackers: These mobile conveyors are used to build large, organized stockpiles of finished products, ready for load-out and shipment.

Building a Cohesive System: The Path to Success

Simply having the right equipment isn't enough. Success in aggregate production comes from how these machines work together as a single, optimized system. A well-designed plant flow ensures maximum uptime, product quality, and profitability.

This is where partnering with an experienced fabricator and solutions provider pays dividends. Companies like Baichy Machinery emphasize that a holistic approach—from custom equipment fabrication and turnkey plant design to expert installation and ongoing technical support—is crucial. They work with you to ensure every component, from heavy-duty crusher bases and custom conveyor sections to complex ductwork, is engineered for durability and seamless integration.

Conclusion: More Than Just Machinery

Aggregate processing equipment is more than just heavy metal; it's the engine that builds our modern world. From the primary bite of a jaw crusher to the precise sorting of a vibrating screen and the relentless movement of a conveyor belt, each piece plays a vital role in creating the fundamental materials for our infrastructure.

Whether you are planning a new operation or optimizing an existing one, understanding this equipment and choosing the right partners for design, fabrication, and service is the first step toward building a rock-solid foundation for the future.

2026-01-06

2026-01-06

86-15093113821

86-15093113821

86-15093113821

86-15093113821