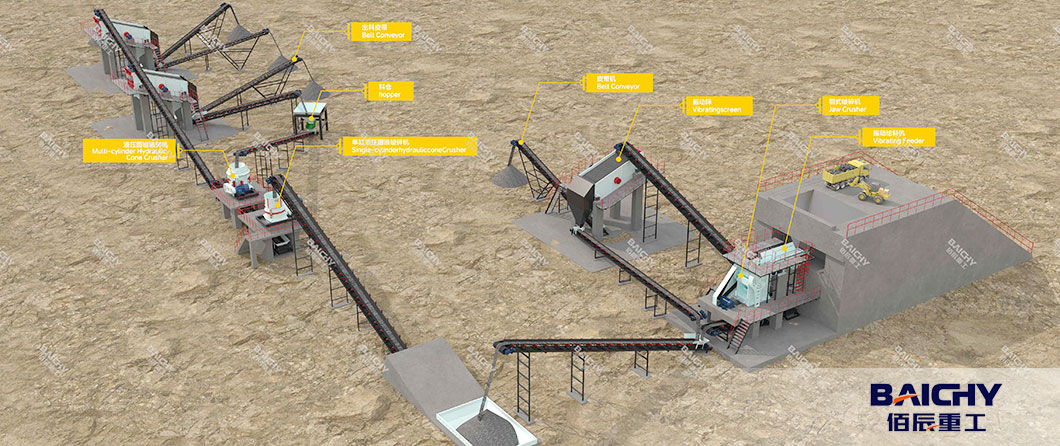

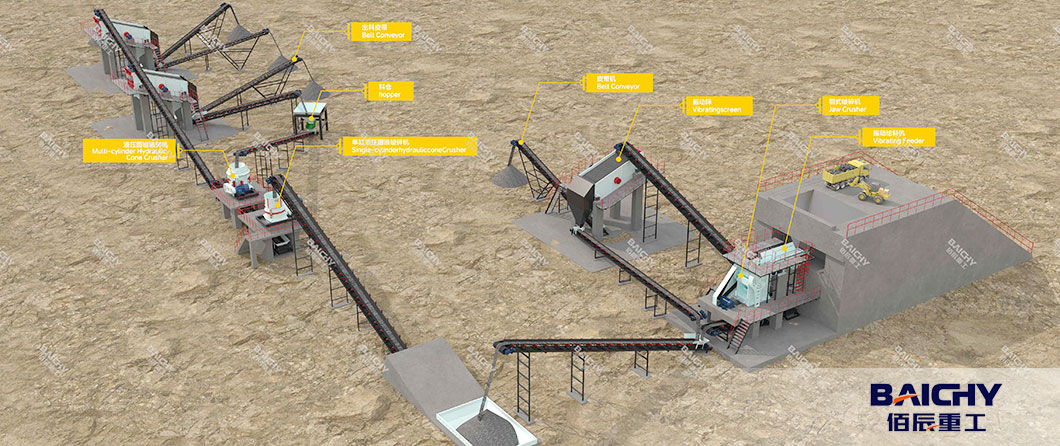

Stone crushing is a multi-stage process that transforms raw rock into usable aggregates for construction, mining, and industrial applications. The equipment used at each stage depends on the rock’s hardness, desired output size, and production volume. Below is a detailed breakdown of the equipment used in each crushing process, along with their applications and benefits.

1. Primary Crushing: Breaking Down Large Rocks

Goal: Reduce large quarry rocks (up to 1,500 mm) into smaller pieces (100–300 mm) for secondary processing.

Key Equipment:

Jaw Crushers

- How it works: Uses a moving jaw plate that compresses rock against a fixed jaw, ideal for hard and abrasive materials (e.g., granite, basalt).

- Types:

- C Series Jaw Crushers: High crushing ratio (6:1), adjustable discharge (10–150 mm), and low energy consumption.

- PE/PEX Jaw Crushers: Robust design for primary crushing in mining and heavy-duty applications.

- Benefits: Simple structure, low maintenance, and high durability.

Gyratory Crushers

- How it works: A conical mantle rotates inside a fixed concave, crushing rock by compression. Suitable for extremely hard rocks in large-scale mining.

- Benefits: High throughput (up to 5,000 TPH), uniform output, and low wear on components.

2. Secondary Crushing: Reducing Particle Size Further

Goal: Break primary crushed material (100–300 mm) into medium-sized particles (20–100 mm) for tertiary crushing or screening.

Key Equipment:

Cone Crushers

- How it works: A mantle rotates within a concave, using compression to crush rock. Ideal for hard materials like quartz and iron ore.

- Types:

- Hydraulic Cone Crushers: Adjustable discharge via hydraulic systems, offering precision and overload protection.

- Spring Cone Crushers: Mechanical overload protection for reliable operation in rugged environments.

- Benefits: High efficiency, cubical particle shape, and low fines production.

Impact Crushers

- How it works: Uses high-speed impact plates to break rock against a stationary anvil. Better for soft to medium-hard rocks (e.g., limestone, sandstone).

- Types:

- Horizontal Shaft Impact (HSI) Crushers: Produce cubical aggregates with minimal fines, suitable for concrete and asphalt.

- Vertical Shaft Impact (VSI) Crushers: Ideal for sand making, using rock-on-rock or rock-on-steel crushing for superior grain shape.

- Benefits: High reduction ratio, low energy use, and versatile particle size control.

3. Tertiary/Quaternary Crushing: Producing Fine Aggregates

Goal: Further reduce particles to fine sizes (5–40 mm) or sand (<5 mm) for final use in construction or industrial applications.

Key Equipment:

VSI Crushers (Sand Making Machines)

- How it works: Accelerates rock particles to high speeds, impacting them against each other or wear plates to create sand and fine aggregates.

- Benefits: High-quality sand with cubical shape, low dust, and adjustable fineness modulus (2.0–3.5).

Hammer Crushers

- How it works: Uses rotating hammers to strike and crush rock against a screen grid, producing fine particles and sand.

- Ideal for: Soft materials like coal, gypsum, and limestone in small to medium-scale operations.

- Benefits: Simple design, low cost, and high reduction ratio.

Roller Crushers

- How it works: Two counter-rotating rolls compress rock into fine particles, suitable for delicate materials that require minimal fines.

- Types:

- Single Roll Crushers: For primary/secondary crushing of soft rocks.

- Double Roll Crushers: For tertiary crushing, producing uniform particles (1–20 mm).

- Benefits: Low noise, minimal dust, and gentle crushing action.

4. Screening and Sorting: Separating Particles by Size

Goal: Classify crushed material into different size fractions for sale or further processing.

Key Equipment:

Vibrating Screens

- How it works: Uses eccentric weights to generate vibration, separating particles across multi-deck screens (e.g., 2–4 decks).

- Types:

- Inclined Screens: High capacity for coarse screening (10–150 mm).

- Horizontal Screens: Precise sizing for fine materials (0.074–50 mm).

- Benefits: High efficiency, adjustable slope, and easy maintenance.

5. Anxillary Equipment: Enhancing Efficiency and Safety

Feeders

- Vibrating Feeders: Uniformly feed rock into crushers, preventing overload and ensuring steady throughput.

- Grizzly Feeders: Pre-screen large rocks to remove fines before crushing, improving crusher efficiency.

Conveyors

- Belt Conveyors: Transport material between equipment, available in inclined or horizontal designs.

- Radial Stacking Conveyors: Pile sorted aggregates into stockpiles for easy loading.

Dust Suppression Systems

- Spray Nozzles/Water Cannons: Reduce airborne dust during crushing and screening, meeting environmental regulations.

- Baghouse Filters: Capture fine dust particles for eco-friendly operations.

Choosing the Right Equipment: Key Considerations

1. Material Hardness:

- Hard rocks (e.g., granite) require jaw or cone crushers.

- Soft rocks (e.g., limestone) can use impact or hammer crushers.

2. Output Requirements:

- Coarse aggregates (e.g., road base): Primary/secondary crushers.

- Fine sand (e.g., concrete): VSI crushers and vibrating screens.

3. Production Scale:

- Small-scale: Portable jaw crushers + hammer crushers.

- Large-scale: Fixed jaw/cone crushers + automated screening systems.

4. Mobility Needs:

- Mobile crushing plants (tracked/wheeled) for remote sites or recycling projects.

Conclusion

Each stage of stone crushing requires specialized equipment to achieve optimal efficiency and product quality. From primary jaw crushers for breaking large rocks to VSI crushers for producing fine sand, the right machinery depends on your material, output goals, and operational scale. By integrating advanced crushing and screening equipment, you can maximize productivity while meeting sustainability and safety standards. For customized solutions, contact Baichy Machinery to explore our range of jaw, cone, and VSI crushers designed for efficiency and durability.

2026-01-05

2026-01-05

86-15093113821

86-15093113821

86-15093113821

86-15093113821