Iron ore concentrate drying is a critical step in mineral processing, as it reduces moisture content in concentrates to meet storage, transportation, and downstream processing requirements (typically 6–12% moisture for optimal handling). An iron ore dryer is specialized equipment designed to efficiently remove surface and capillary moisture from iron ore concentrates using thermal energy, ensuring the material remains stable, flowable, and suitable for smelting, pelletizing, or shipping.

Key Functions of an Iron Ore Dryer

● Moisture Reduction: Lowers moisture levels in iron ore concentrates (often from 15–30% to 5–10%) to prevent caking, clumping, or degradation during storage/transport.

● Improved Process Efficiency: Dry concentrates enhance the performance of subsequent steps, such as pelletizing (uniform moisture ensures better pellet strength) or smelting (reduces energy consumption by eliminating excess water).

● Material Preservation: Prevents oxidation, bacterial growth, or chemical changes caused by high moisture, maintaining concentrate quality.

Iron Ore Dryers - Single Drum Rotary Dryer

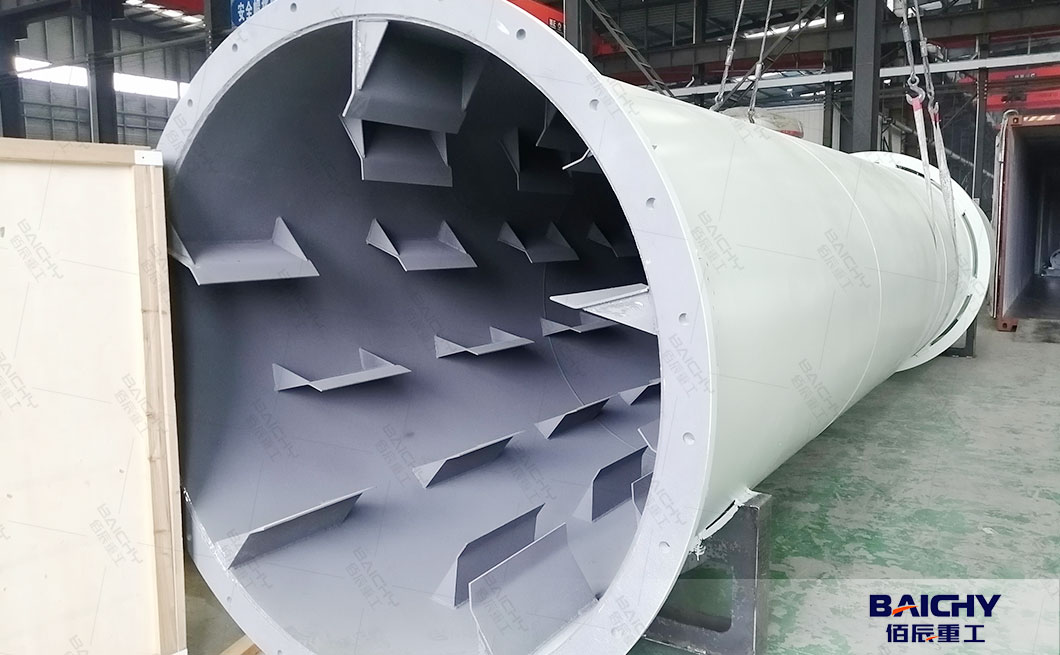

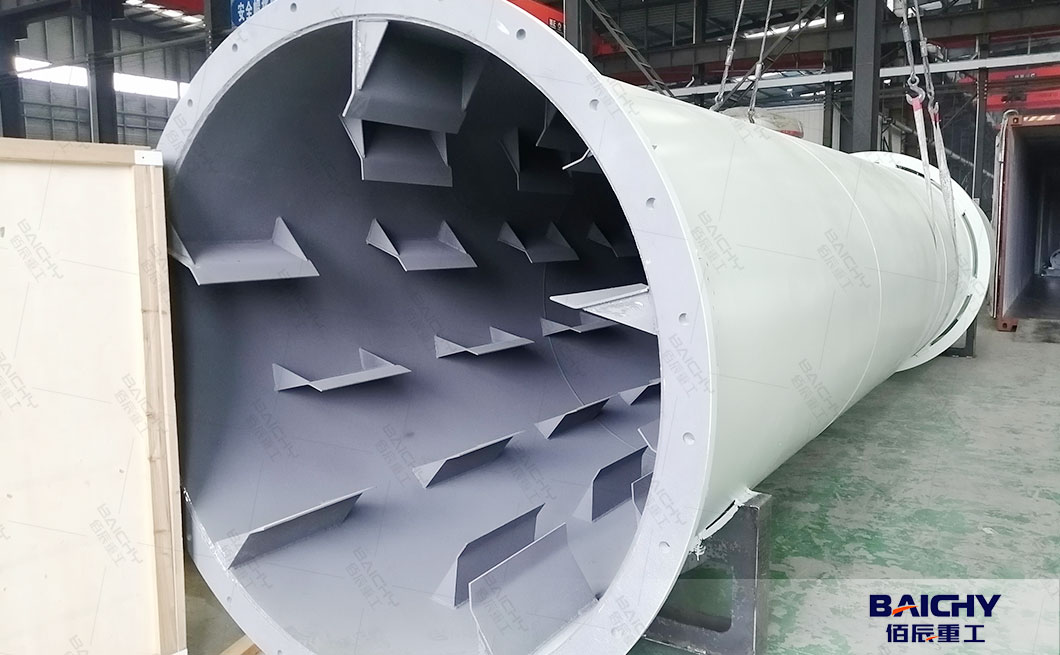

Single drum rotary dryer designs are used based on concentrate properties (particle size, moisture content, viscosity) and processing scale. It is used for iron ore concentrate drying, rotary dryers feature a rotating cylindrical drum inclined at a slight angle.

Working Principle:

Wet concentrates are fed into the drum, where they are lifted and cascaded by internal flights (paddles) as the drum rotates. Hot air (from burners using coal, natural gas, or biomass) flows countercurrent or cocurrent with the material, transferring heat to evaporate moisture.

Advantages:

● Handles large capacities (10–500 tons/hour), suitable for industrial-scale operations.

● Adaptable to varying concentrate particle sizes (from fine powders to coarse grains).

● High thermal efficiency (up to 70–80%) with adjustable residence time.

● Considerations: Requires proper sealing to prevent dust leakage; optimal for free-flowing concentrates.

Key Considerations in Selecting an Iron Ore Dryer Models

1. Concentrate Properties:

● Particle Size: Fine powders may require flash dryers to avoid clogging; coarser grains work well in rotary dryers.

● Initial Moisture: High-moisture concentrates (e.g., 25–30%) benefit from rotary dryers with longer residence times.

● Stickiness/Agglomeration: Sticky materials need designs with anti-caking features (e.g., special flights in rotary dryers or dispersing mechanisms in flash dryers).

2. Energy Source:

● Choose fuel based on cost and availability: natural gas (clean, high efficiency), coal (low cost for large-scale operations), biomass (sustainable), or waste heat from other processes (e.g., smelting off-gases) to reduce energy costs.

3. Capacity Requirements:

● Match dryer throughput to upstream processing (e.g., grinding, beneficiation) to avoid bottlenecks. Rotary dryers are preferred for high-capacity plants (100+ tons/hour), while flash dryers suit medium-scale operations.

4. Environmental Compliance:

● Ensure the dryer integrates with dust collectors (baghouses, cyclones) to meet emissions standards. Low-NOx burners reduce nitrogen oxide emissions, critical for eco-friendly operations.

5. Operational Efficiency:

● Look for features like adjustable air flow/temperature, automated moisture control (via sensors), and easy maintenance (e.g., accessible drum internals) to minimize downtime.

Typical Drying Process Flow

● Feed Preparation: Wet iron ore concentrate (from filtration or thickening) is fed into a hopper, often with a screw conveyor to control flow rate.

● Drying Stage: The concentrate enters the dryer, where it contacts hot air/ gases to evaporate moisture.

● Separation: Dried concentrate is separated from exhaust air using cyclones or filters.

● Product Handling: Dry concentrate is stored in silos or conveyed to pelletizing plants, smelters, or shipping facilities.

Why Efficient Drying Matters

● Cost Savings: Reduces transportation costs (moisture adds weight) and prevents storage losses from caking.

● Quality Assurance: Consistent moisture levels ensure uniform pelletizing and smelting, improving final iron product quality.

● Sustainability: Modern dryers with heat recovery systems (e.g., recirculating exhaust air) lower energy use and carbon footprints.

In summary, selecting the right iron ore dryer depends on material characteristics, production scale, and operational goals. Whether optimizing for speed, capacity, or energy efficiency, a well-chosen dryer is essential for a smooth, cost-effective iron ore concentrate processing chain. Henan Baichy Machinery Equipment Co., Ltd. is a mining machinery manufacturer integrating R&D, production and sales. Rotary is one of our production equipment. It has mature technology and processes, complete models and configurations, and technical engineers can tailor production line configuration plans for you. If you are interested in it, please click on the online consultation to get solution and price now. Baichy Machinery is dedicated to serving you 24 hours a day!

People Also Frequently Asked For - FAQ

1. What is another name for a rotary dryer?

Vernacular Names: Drum Dryer, Rotating Dryer, Rotary Kiln Dryer, Rotating Tube Dryer, Sawdust Dryer, Spin Dryer, Tube Dryer, Wood Chip Dryer etc.

2. What are the different types of rotary dryers?

They are the most widely used and are divided into three types: conventional direct heating rotary dryers, blade-through-flow rotary dryers, and ventilated rotary dryers.

3. What is the difference between a rotary kiln and a rotary dryer?

Rotary dryers are used for drawing moisture out of a material. As such, they typically operate at temperatures between 800º – 1400ºF. In contrast, rotary kilns are used to cause a chemical reaction or phase change, requiring them to operate at much higher temperatures, typically between 1000º – 3000ºF.

2026-01-05

2026-01-05

86-15093113821

86-15093113821

86-15093113821

86-15093113821