If you are engaged in mining, construction or any industry that relies on material crushing and processing, you may ask: How many types of mills are there? The answer is not uniform - there are numerous types of mills, each designed for specific tasks, materials and production volume requirements. But if we classify them by core functions and industrial applications, the most crucial types will become clear.

First, let's simply define what a mill is: a machine used for grinding, crushing, cutting or processing raw materials to turn them into smaller particles, powders or special products. The key to understanding the types of mills lies in two main factors: the material you are processing (ores, grains, textiles, etc.) and your processing method (grinding, impact, rolling, etc.). For industrial and mining, we will focus on the types that are most important for heavy-duty applications.

Industrial grinding mills can handle a wide range of materials, from hard rock ores to mineral concentrates. Here are the most common and important types of grinding mills. Industrial grinding mills are usually classified according to the way they crush materials, but they typically fall into three mechanical forces.

One is the drum mill, which relies on wear and impact forces. Imagine a rotating cylinder filled with heavy steel balls or rods, which collide with the ore. The other is the compression mill, where rollers use tremendous pressure to press the material onto a ring or flat surface. Finally, there is the impact mill, which uses a high-speed rotor to impact the material onto the liner.

In the mining and aggregate processing industries, you need to be familiar with the following four main types of equipment.

1. Ball mill

The ball mill is a simple horizontal rotating cylinder filled with steel balls. As the cylinder rotates, the steel balls fall and crush the ore. It is not a high-tech device, but it is extremely durable. It is the preferred choice for hard metals such as gold, copper, and iron ore. If you need to do wet grinding (to make a slurry), it is also the only option.

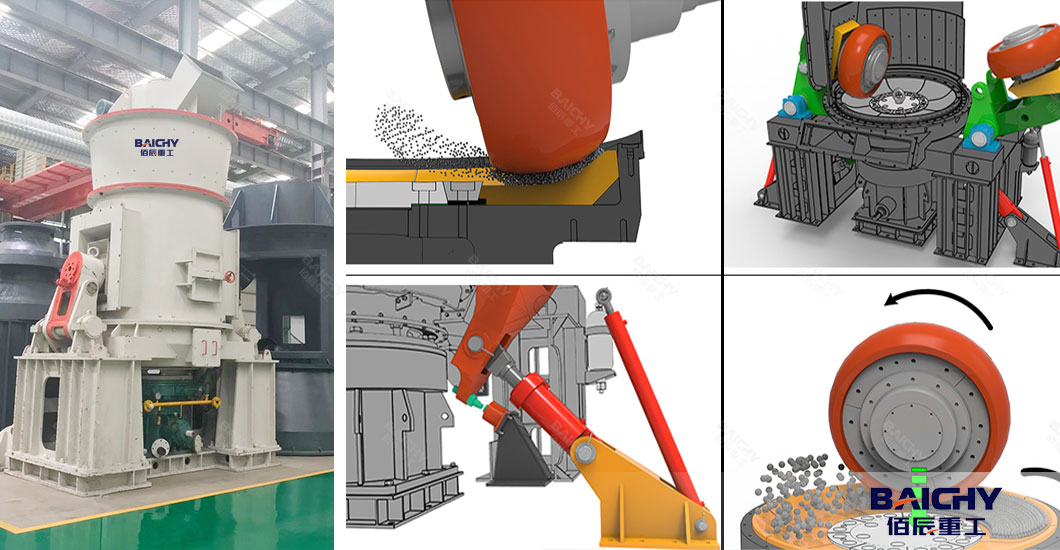

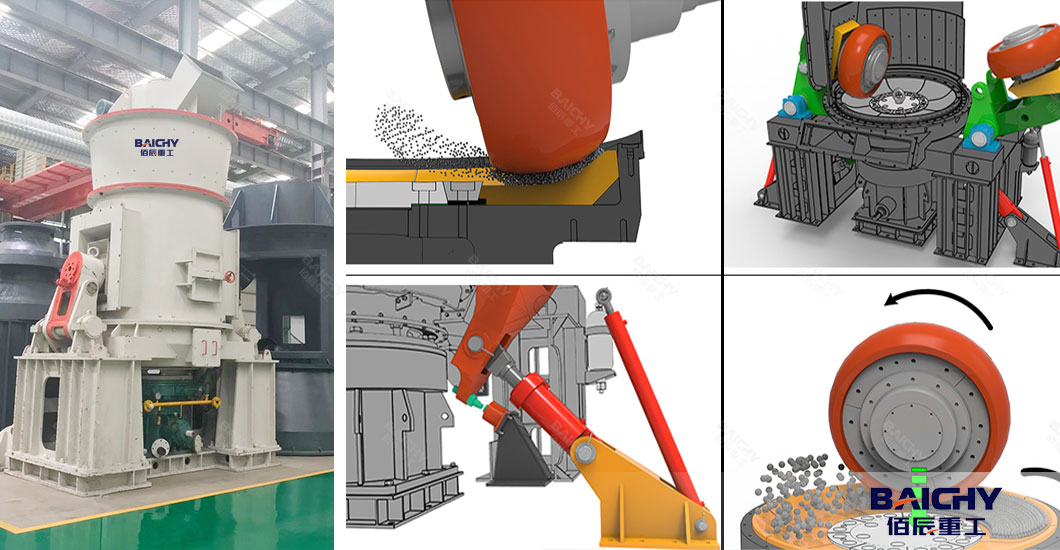

2. Raymond mill (Swing mill)

If you are processing non-metallic minerals - such as limestone, calcite, gypsum, or barite - the ball mill usually seems oversized and inefficient. At this point, the Raymond mill comes into play.

Inside this vertical device, the suspended rollers swing outward due to centrifugal force and tightly press against the grinding ring. Its real advantage lies in the built-in air classifier. It can produce very uniform fine powder (80-425 mesh) at one time, which is very suitable for use as industrial fillers.

3. Vertical roller mill (VRM)

When you need large-scale and efficient production, you will choose the vertical roller mill. You will see their presence in cement plants and large coal processing plants. It uses heavy hydraulic rollers to crush the materials on the rotating platform. This is a complex device that integrates drying, grinding, and separation functions. It consumes less energy than the ball mill, but the initial installation cost is higher.

4. Hammer mill

This is a standard hammer mill. It uses a high-speed rotor with swinging hammers. It is very suitable for processing soft and non-abrasive materials such as coal or agricultural products. It has a high crushing ratio, but please note - if you send hard and abrasive rocks into the impact crusher, the wearing parts will be damaged quickly.

Choosing the Right Grinding Mill

Choosing a grinding mill is not merely about selecting the cheapest equipment; it involves considering the physical principles as well. If you put hard granite into a Raymond mill, the rollers will be damaged. If you put soft gypsum into a ball mill, you will waste electricity.

To make the right choice, you should first check the Mohs hardness.

If your material is hard (with a Mohs hardness of 7 or above), a ball mill's rolling action is usually required. Steel grinding media can withstand the impact and protect the machine itself. If the rock's hardness is medium or softer (below 7 on the Mohs scale), a Raymond mill or a vertical mill is more efficient.

Next, check your discharge particle sizeFor coarse products (0-3 mm), a simple hammer crusher or rod mill will suffice. But if you need fine powder (200 mesh or higher), you will need the air classification system used in the Raymond mill.

Finally, consider the moisture content. Ball mills are suitable for processing wet materials; they are very suitable for wet grinding. However, Raymond mills are not. If you send damp, sticky rocks into a Raymond mill, it will immediately get clogged.

So when choosing the right mill, ask yourself a few questions: What is the hardness and moisture content of the ore? What is the required particle size of the target product? Is it a dry process or a wet process? What is the budget?Answer these questions, and you can move beyond the "how many types" list and find the one that truly meets the mining site's needs. Henan Baichy Machinery is a well-known manufacturer and supplier of powder grinding equipment, and provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly. Contact us to get professional solutions now.

People Also Frequently Asked For - FAQ

1. How many types of industrial mills are there in total?

While there are dozens of specialized variations used across food, pharmacy, and manufacturing, the mining and aggregate industry primarily relies on four main types: Ball Mills, Raymond Mills (Pendulum), Vertical Roller Mills (VRM), and Hammer Mills. These four cover about 90% of all stone grinding applications.

2. What is the difference between a "Milling Machine" and a "Grinding Mill"?

This is a common confusion. A "Milling Machine" (often called a CNC mill) is a workshop tool used to cut and shape metal or wood. A "Grinding Mill" (like a Ball Mill or Raymond Mill) is heavy machinery used to crush rocks and minerals into powder. They are completely different tools for different industries.

3. Which mill is best for hard, abrasive rock?

The Ball Mill is the standard choice for hard materials (Mohs hardness 7 and above), such as quartz, gold ore, and iron ore. It uses tumbling steel balls to break the rock. Other mills, like the Raymond Mill, rely on rollers that will wear out too quickly if used on hard, abrasive stone.

4. Can all mills perform wet grinding?

No. Ball Mills and Rod Mills are excellent for wet grinding (mixing ore with water to create a slurry). However, Raymond Mills and Hammer Mills are designed strictly for dry grinding. Feeding wet or sticky material into them will clog the machine and stop production.

2026-01-13

2026-01-13

86-15093113821

86-15093113821

86-15093113821

86-15093113821