Clinker— the key raw material for cement production—requires precise grinding to achieve uniform fineness (typically 300–450 m²/kg Blaine) for optimal cement performance. A complete closed-circuit clinker ball mill plant with 12 TPH (tons per hour) capacity is tailored for small-to-medium cement factories, building material suppliers, and regional construction hubs. Last week, we deliver the clinker ball mill 2400x8000 to Saudi Arabia.

What is a Closed-Circuit Clinker Grinding Plant?

In a ball mill grinding system, "circuit" refers to the path the material takes.

● Open Circuit: Material passes through the ball mill once. To ensure all particles are fine enough, the material must stay in the mill longer, which leads to "over-grinding," high heat, and wasted energy.

● Closed Circuit: The ball mill works in tandem with a High-Efficiency Powder Separator (Classifier). Ground material exits the mill and enters the separator.

○ Fine powder (Finished Product) is collected.

○ Coarse powder (Returns) is sent back to the mill inlet for regrinding.

This recirculation loop allows the material to pass through the mill quickly, preventing over-grinding and significantly boosting efficiency.

Why Choose a Closed-Circuit Ball Mill for Clinker Grinding?

Unlike open-circuit systems that pass material through the mill only once, a closed-circuit system incorporates a separator (often an air classifier). Fine product is removed, while coarse material is recirculated back to the mill for further grinding. This setup is critical for clinker grinding for several reasons:

● Superior Product Quality: It allows for precise control over the final product's fineness (Blaine), ensuring a consistent and high-quality cement that meets industry standards.

● Higher Energy Efficiency: By preventing over-grinding of fine particles, the system uses energy more efficiently, significantly reducing power consumption per ton of cement produced.

● Increased Capacity: The closed-circuit design boosts the mill's throughput by ensuring only oversized particles are ground further, maximizing the 12 TPH capacity.

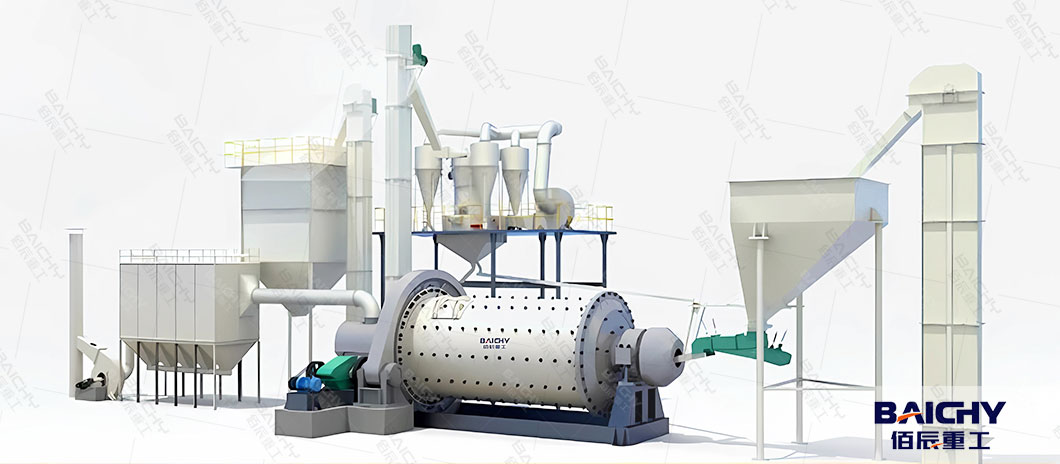

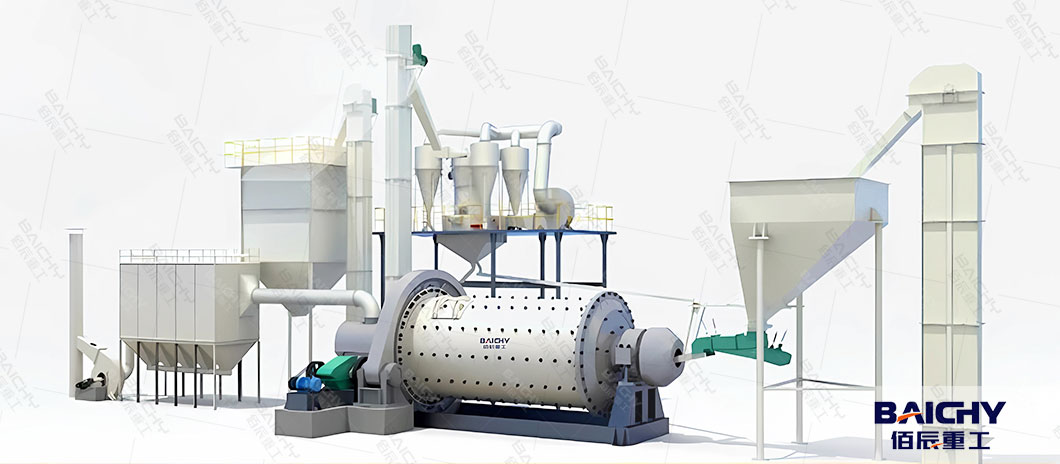

Key Components of a Complete 12 TPH Clinker Ball Mill Plant

A "complete cement mill plant" is a fully integrated system designed for seamless operation. Our standard package includes:

1. Feed System: A controlled feeding mechanism, such as a weigh feeder or screw conveyor, ensures a consistent and steady supply of clinker, gypsum, and other additives into the mill.

2. The Ball Mill: The core of the plant. For a 12 TPH capacity, a robustly constructed ball mill, lined with durable wear-resistant materials, is used. It is filled with grinding media (balls) that reduce the clinker to a fine powder.

3. Dynamic Separator / Air Classifier: This vital component classifies the ground material from the mill, separating the fine product (cement) from the coarse grit. The coarse material is efficiently returned to the mill inlet for regrinding.

4. Dust Collection System: A high-efficiency baghouse or dust collector is essential for meeting environmental standards, capturing airborne particles, and ensuring a clean working environment.

5. Material Handling & Transport: This includes bucket elevators, pneumatic conveying systems, and screw conveyors that move material between the mill, separator, and product silos.

6. Process Control System: A modern PLC-based control panel automates the entire grinding process, allowing for precise monitoring and adjustment of key parameters like feed rate, mill temperature, and power consumption.

A complete 12 TPH closed-circuit clinker ball mill plant represents a smart investment in efficiency, quality, and sustainability. It is a proven technology that delivers exceptional value for medium-capacity production needs.

Contact us today to speak with our engineering team. We can provide detailed specifications, layout drawings, and a competitive quotation tailored to your specific project requirements. Let us help you build a more profitable and efficient grinding operation.

People Also Frequently Asked For - FAQ

1. What is the closed-circuit cement clinker ball mill system?

A closed-circuit system refers to a process where the material is ground in a mill, then sorted by a classifier, with the qualified fine powder being output and the coarse powder being returned to the mill for further grinding. This system has low energy consumption and stable product fineness, and is a standard configuration for modern cement production.

2. What are the core advantages of this system?

Compared to open-loop systems, the closed-loop system can save 15-25% of energy. The fineness of the product can be precisely controlled within 300-450㎡/kg. Moreover, through sorting control, the phenomenon of excessive grinding is avoided, and the production capacity is increased by approximately 20%.

3. What are the key equipment included in the system?

Mainly include: feeding system, ball mill, high-efficiency classifier (such as O-Sepa), dust collection system, fans and automatic control system. The efficiency of the classifier directly affects the system's energy consumption and product quality.

4. What are the equipment investment and construction period like?

Based on the production capacity configuration (usually 30-100 tons per hour), the investment range is approximately 80-300 million US dollars, including equipment, foundation and installation. From design to commissioning, it takes about 6-9 months. The specific period depends on the degree of automation and on-site conditions.

2026-02-11

2026-02-11

86-15093113821

86-15093113821

86-15093113821

86-15093113821