A 200t/h crushing plant is a integrated production line designed to process 200 tons of raw rock per hour into usable construction aggregates (5–63mm). Unlike small-scale crushers, it uses a multi-stage crushing + screening workflow to ensure uniform particle size, cubical shape, and minimal waste—critical for high-performance concrete, asphalt, and road base.

Ideal for:

● Large construction projects (highways, railways, airports).

● Quarries supplying aggregates to concrete mixing stations.

● Infrastructure developers needing on-site or centralized aggregate production.

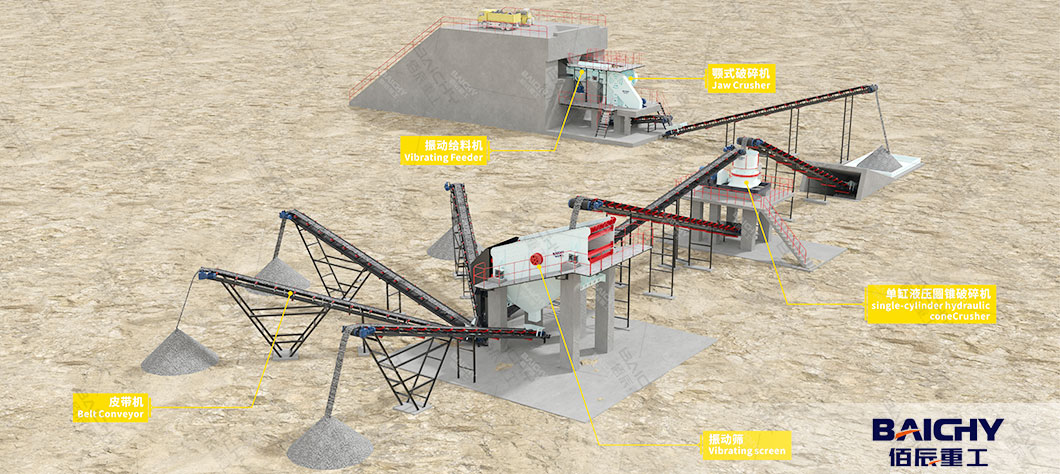

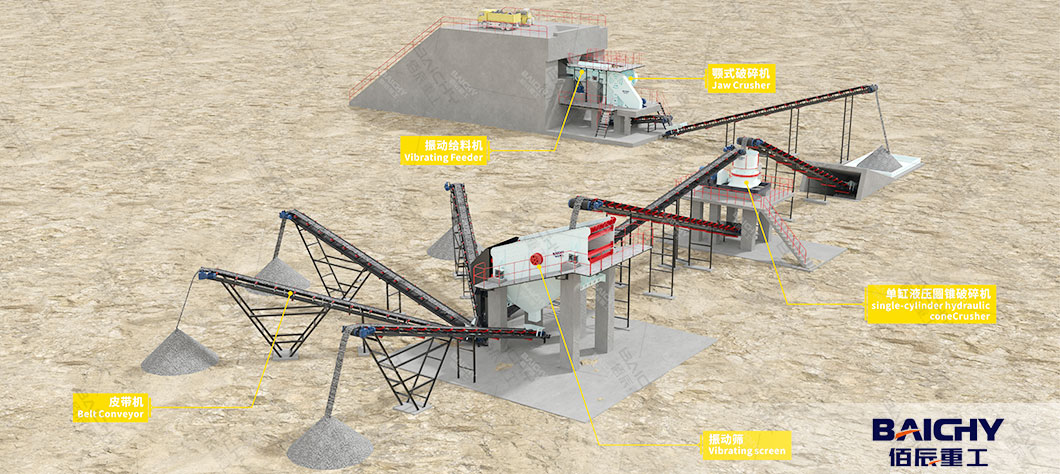

Core Equipment of the 200t/h Aggregate Crushing Plant

Every component is sized to match 200tph capacity, avoiding bottlenecks and ensuring smooth operation:

1. Vibrating Feeder (ZSW1360)

Role: Feeds raw rock (up to 600mm lumps) evenly into the primary crusher, preventing overload.

Key Specs: 1300×6000mm feed size, 200–300t/h capacity, 30kW motor.

Advantage: Grizzly bars filter out fine dust (≤50mm) to protect downstream crushers and boost efficiency.

2. Primary Crusher: Jaw Crusher (PE750×1060)

Role: First-stage crushing—reduces large rock lumps to 40–100mm intermediate material.

Key Specs: jaw crusher 750×1060mm feed opening, 80–140t/h capacity, 55kW motor.

Advantage: Manganese steel jaw plates resist wear from hard rocks (granite, basalt), lasting 4–6 months in continuous use.

3. Secondary Crusher: Impact Crusher (PF1315)

Role: Refines intermediate material into 10–40mm cubical aggregates (ideal for concrete/asphalt).

Key Specs: 1320×1500mm crushing chamber, 100–180t/h capacity, 160kW motor.

Advantage: High-speed blow bars deliver impact force for brittle/medium-hard rocks (limestone, dolomite), producing aggregates with <20% flakiness rate.

4. Tertiary Crusher/Scrubber (Optional): VSI1145 Vertical Shaft Impact Crusher

Role: Produces high-quality sand (5–10mm) or ultra-fine aggregates for precast concrete.

Key Specs: 60–120t/h capacity, 180kW motor.

Advantage: “Stone-on-stone” crushing ensures round, durable sand that replaces natural sand (eco-friendly alternative).

5. Screening Unit: 4YK1860 Four-Deck Vibrating Screen

Role: Classifies crushed material into 4 graded aggregates (e.g., 5–10mm, 10–20mm, 20–31.5mm, 31.5–63mm).

Key Specs: 1800×6000mm screen size, 200–250t/h capacity, 45kW motor.

Advantage: High-frequency vibration (16–18Hz) ensures 98% screening efficiency—no oversized particles in finished aggregates.

6. Belt Conveyors & Storage Silos

Conveyors: 3–5 belt conveyors (width 800–1000mm) transport material between crushers/screens—sealed design reduces dust.

Silos: 200–500-ton sealed silos store finished aggregates, preventing moisture absorption and contamination.

How the 200t/h Crushing Plant Works (Simplified Workflow)

● Feeding: Raw rock (e.g., limestone boulders) is loaded into the ZSW1360 vibrating feeder via excavator.

● Primary Crushing: Feeder delivers rock to the PE750×1060 jaw crusher, reducing it to 40–100mm.

● Secondary Crushing: Intermediate material moves to the PF1315 impact crusher for shaping into 10–40mm cubical particles.

● Screening: 4YK1860 screen sorts material into 4 graded aggregates—oversized particles return to the impact crusher for reprocessing.

● Storage/Discharge: Qualified aggregates are conveyed to silos or directly loaded into trucks for delivery to job sites.

4 Key Benefits of the 200t/h Aggregate Crushing Plant

1. Consistent 200tph Production

Optimized equipment matching ensures steady output—no fluctuations that delay construction projects. A quarry in Texas reports 95% uptime, producing 1,600 tons per 8-hour shift to supply a highway expansion.

2. High-Quality Aggregates

Multi-stage crushing + screening delivers cubical, uniform particles with low flakiness (≤15%)—critical for concrete strength (28-day compressive strength ≥40MPa) and asphalt durability. Meets global standards for road and building materials.

3. Energy-Efficient & Cost-Saving

Total power consumption is 350–400kW, translating to ~1.8–2.0 kWh per ton of aggregate—20% less than inefficient, mismatched equipment. Reduces raw material waste to <5% (95% of rock becomes usable aggregate).

4. Easy Operation & Low Maintenance

PLC touchscreen control: One operator manages the entire line, adjusting crusher gaps and screen settings remotely.

Accessible wear parts: Jaw plates, blow bars, and screen meshes are easy to replace (2–4 hours), minimizing downtime.

A 200t/h crushing plant is the ultimate solution for meeting large-scale construction aggregate demand. Its efficient workflow, consistent output, and high-quality aggregates make it a smart investment for quarries, construction firms, and infrastructure developers. For a customized 200t/h aggregate crushing plant (tailored to your raw material, desired aggregate sizes, and budget), contact our team for a free quote and layout design.

FAQs About 200t/h Aggregate Crushing Plants

1. What raw materials can it process?

Works with medium-to-hard rocks: limestone, granite, basalt, dolomite, gravel, and recycled concrete. Adjust crushers (e.g., use cone crusher instead of impact crusher for ultra-hard granite) for different materials.

2. Does it meet environmental standards?

Yes—equipped with pulse bag filters (captures 99.5% of dust) and noise reduction liners (≤85dB). Complies with US EPA, EU IPPC, and local emission regulations.

3. How much space does it require?

A standard setup needs 1,000–1,500㎡ (10,760–16,146 sq ft) of flat land—no concrete foundation required for mobile versions (optional for fixed plants).

4. What’s the typical investment range?

Prices start at 350,000–600,000, depending on configuration (e.g., with/without VSI crusher, mobile/fixed design). ROI is typically 12–18 months for busy quarries or project-focused operations.

2026-01-04

2026-01-04

86-15093113821

86-15093113821

86-15093113821

86-15093113821