Calcium carbonate (GCC) is more than just a filler; it is a critical performance enhancer in industries from plastics and paints to pharmaceuticals and sealants. Its effectiveness, however, is directly tied to its particle size distribution and top-cut. To move beyond coarse fillers into the high-value market of ultra-fine calcium carbonate powder, a standard grinding mill is not enough. The solution lies in a technologically advanced dry ball mill integrated with a high-efficiency air classifier.

The Challenge: Beyond Simple Grinding

● Producing ultra-fine powder (typically ranging from D97 45 microns down to D97 5 microns) presents two main challenges:

● Energy Efficiency: A standard ball mill alone will continue to grind all particles, including those already at the target size. This "over-grinding" wastes a tremendous amount of energy and can even degrade the product quality.

● Precise Particle Size Control: It is nearly impossible to achieve a tight, consistent particle size distribution with a mill alone. A narrow distribution is crucial for properties like opacity in paint, strength in plastics, and viscosity control in adhesives.

The Solution: A Closed-Loop Grinding and Classification System

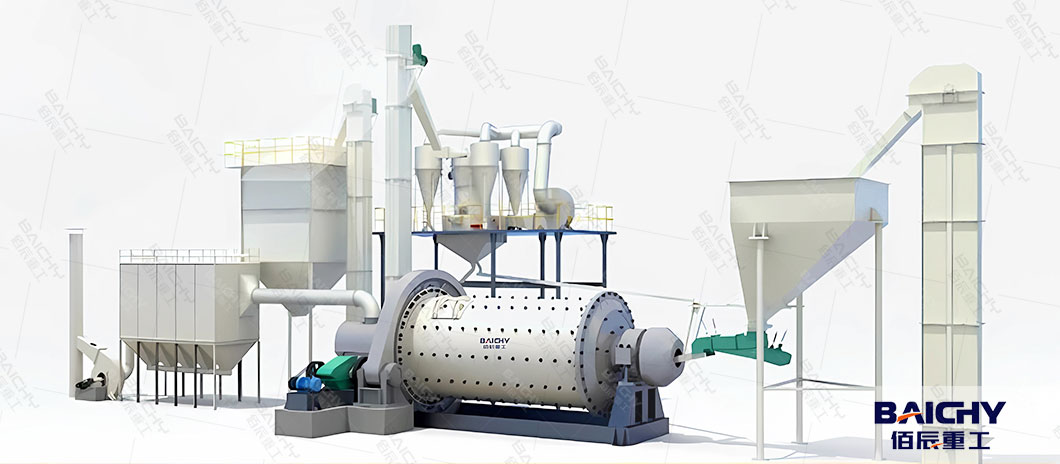

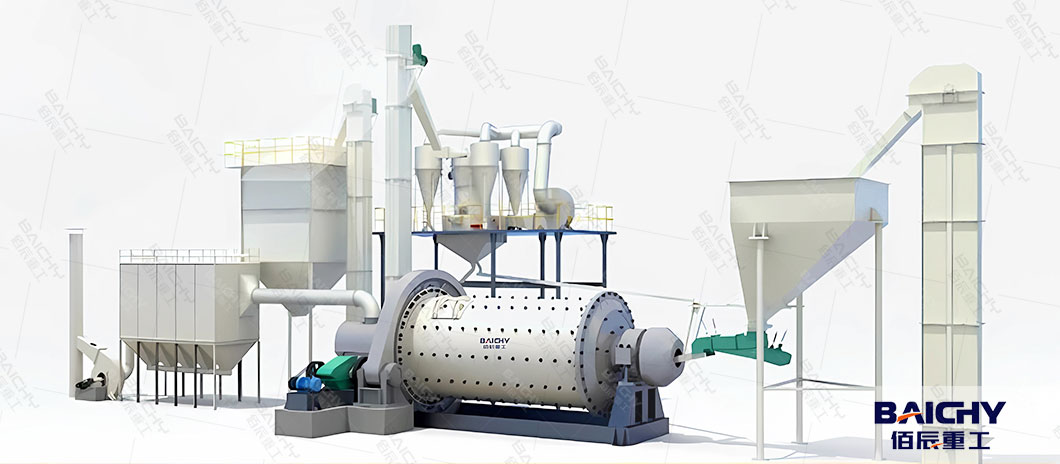

An ultra-fine ball mill with a dynamic air classifier solves these challenges by creating an intelligent, closed-loop system. Here's how it works:

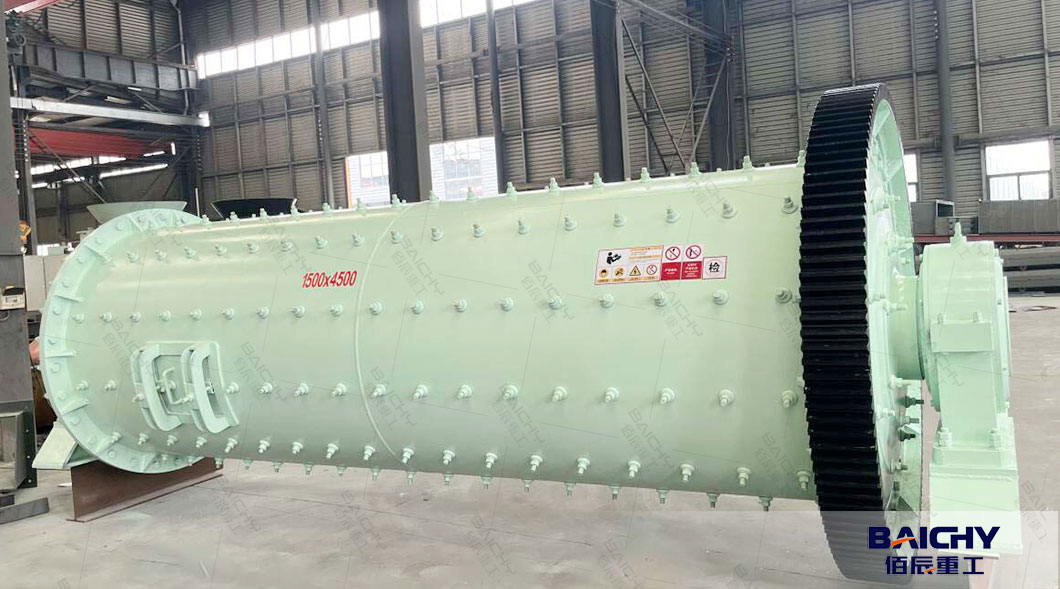

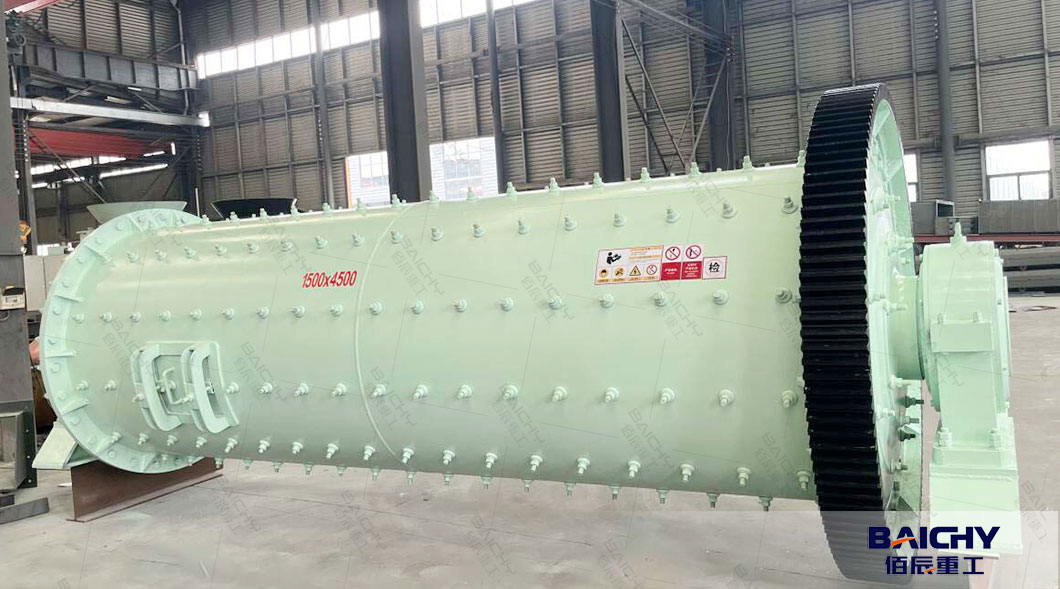

● Grinding: The feed material (crushed, dry limestone of 1-3mm) enters the ball mill. Inside the rotating chamber, steel balls impact and attrition the calcium carbonate, reducing its size through collisions.

● Classification: The mill discharge is transported by an air stream to the integrated high-efficiency air classifier. This is the brain of the operation.

● Separation: The classifier wheel spins at a high, adjustable speed. Centrifugal force acts against the drag force of the air.

● Fine Particles: Particles smaller than the target size (fines) have low mass and are overcome by the air drag. They pass through the classifier wheel and are sent to the product collection cyclone and baghouse filter.

● Coarse Particles: Particles larger than the target size (oversize) have high mass and are thrown back by centrifugal force. They are rejected from the classifier and returned to the ball mill for further grinding.

This continuous separation and re-grinding process ensures that energy is used only on the particles that need to be reduced, maximizing efficiency and guaranteeing a uniform final product.

Key Advantages of the Ball Mill + Classifier System

Precise Particle Size Control: Achieve consistent fineness from D97 45 microns down to D97 5 microns simply by adjusting the speed of the classifier rotor. A higher speed yields a finer powder.

● High Energy Efficiency: By eliminating over-grinding, the system can reduce energy consumption by up to 30-50% compared to a traditional open-circuit ball mill producing the same product.

● Narrow Particle Size Distribution: The sharp cut of the modern classifier ensures a tight PSD, which translates to better performance in the final application (e.g., improved gloss in paints, higher impact strength in plastics).

● High Production Capacity: This system is designed for continuous, high-volume production, making it ideal for large-scale industrial plants.

● Product Flexibility: With quick classifier speed adjustments, the same system can produce different product grades for various customers, enhancing market agility.

Why This System is Ideal for Calcium Carbonate

Calcium carbonate is a perfect material for this technology. The system can be tailored to its specific properties:

● Whiteness Preservation: The closed system prevents contamination and can be lined with ceramics or special steel to minimize iron contamination, protecting the bright whiteness of the GCC.

● Thermal Sensitivity: Dry grinding generates heat, but the constant air flow in a closed circuit acts as a cooling mechanism, preventing thermal degradation of the carbonate.

● Wide Range of Applications: The system can be tuned to produce everything from a coarse 800 mesh (19µm) powder for cheaper fillers to an ultra-fine 2500 mesh (5µm) powder for high-end masterbatch and coatings.

Final Product Applications

The ultra-fine, high-purity calcium carbonate produced by this system is essential for:

● Paints & Coatings: As a extender pigment providing opacity, improved sheen control, and enhanced durability.

● Plastics & Polymers: To improve stiffness, impact strength, and surface finish (e.g., in PVC pipes, profiles, and polypropylene compounds).

● Adhesives & Sealants: As a functional filler to control viscosity, sag resistance, and mechanical properties.

● Paper: As a coating pigment to create a smooth, bright, and opaque printing surface.

● Rubber: To enhance tensile strength and tear resistance.

Conclusion

Investing in an ultra-fine ball mill with an integrated air classifier is not merely a purchase of grinding equipment; it is an investment in product quality, operational efficiency, and market positioning. For calcium carbonate producers, this technology is the definitive path to upgrading from commodity fillers to high-value, specification-grade products that command premium prices and drive growth in advanced industrial sectors.

Ready to produce premium-grade calcium carbonate powder? Contact us today to discuss your production requirements and receive a customized proposal for a ball mill-classifier system tailored to your specific needs.

2026-01-06

2026-01-06

86-15093113821

86-15093113821

86-15093113821

86-15093113821