The stone crushing plant typically operates in three main consecutive stages - primary, secondary and tertiary, aiming to break the raw quarry rock into specific aggregate sizes. This process involves sending the raw materials to the primary crusher (such as a jaw crusher), and then further crushing them in the secondary/tertiary crushers (such as a cone crusher or impact crusher). The consistency of size is ensured through screening and transportation between each stage.

This article comprehensively introduces the primary, secondary and tertiary crushing processes. We will delve into each stage of the crushing process, discussing the types of crushers used, their working principles, common applications, and the differences between them and other crushing processes. We will also address some common questions regarding how to select the appropriate type of crusher and how to maintain the efficiency of the crushers. After reading this article, readers will have a deeper understanding of the crushing process and its significance in the aggregate industry.

1. Feeding

Raw material supply: The process begins with the delivery of raw materials to the stone crusher plant. These raw materials can be mined ores such as limestone, granite, iron ore, or construction and demolition waste. The materials are usually transported to the plant by trucks, conveyor belts from a nearby quarry or storage area.

Hopper and feeder: The raw materials are first loaded into a hopper. The hopper acts as a temporary storage container and helps to regulate the flow of materials into the crusher. A feeder, often a vibrating feeder, is used to control the rate at which the material is fed into the stone crusher. This ensures a consistent and continuous supply of material to the crushing unit.

2. Primary Crushing

Crushing operation: The primary crusher is the first stage of size reduction. Jaw crushers are commonly used as primary crushers. In a jaw crusher, the material is squeezed between a stationary jaw and a moving jaw. As the moving jaw reciprocates, it applies pressure to the material, breaking it into smaller pieces. The output of the primary crusher typically ranges from a few inches to a foot in diameter, depending on the crusher settings and the characteristics of the input material.

Product sizing: After the primary crushing, the material is screened through a grizzly screen or a vibrating screen. Oversized particles are returned to the crusher for further reduction, while the properly sized material passes through to the next stage.

3. Secondary Crushing

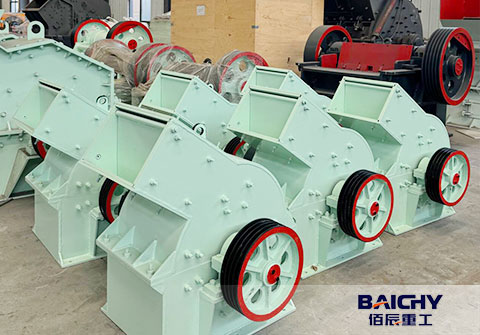

Further size reduction: The secondary crusher further reduces the size of the material. Cone crushers or impact crushers are often used at this stage. Cone crushers work by compressing the material between an eccentrically rotating mantle and a stationary concave. Impact crushers, on the other hand, use the principle of impact to break the material. The secondary crusher can produce material with a size range from a few millimeters to several inches.

Classification: The crushed material is then classified again. This may involve the use of vibrating screens with different mesh sizes to separate the material into different fractions. The goal is to obtain a more uniformly sized product and to separate out any remaining oversized particles for additional crushing.

4. Tertiary Crushing (Optional)

Fine - crushing: In some cases, a tertiary crusher is used to achieve an even finer product size. Vertical shaft impact crusher VSI crushing machine or vertical shaft impact crushers can be used for this purpose. This stage is especially important when producing materials for applications that require a very fine and consistent particle size, such as in the production of sand for construction or in the preparation of certain minerals for industrial processes.

5. Screening and Sorting

Screening process: Multiple - deck vibrating screens are used to separate the crushed material into different size fractions. The YK vibrating screens have different mesh sizes, and the material is separated based on whether it can pass through the holes in the screen. This allows for different grades with specific size ranges, such as coarse aggregates, medium aggregates, and fine aggregates.

Sorting for quality control: In addition to size sorting, magnetic separators or other sorting devices may be used to remove unwanted impurities such as metal fragments from the crushed material. This is an important step for ensuring the quality of the final product and for meeting the specifications of the end - use application.

6. Washing and Cleaning (Optional)

Washing process: If the crushed material contains a significant amount of clay, silt, or other fine - grained impurities, a washing stage may be included. Aggregate washing plants use water and a combination of scrubbing and rinsing to remove the impurities. This is particularly common in the production of sand and gravel for construction purposes, as clean aggregates are preferred for better concrete quality and other applications.

Slurry treatment: The water used in the washing process becomes a slurry containing the removed impurities. This slurry needs to be treated to separate the solids from the liquid. Settling ponds or mechanical dewatering equipment such as centrifuges or filter presses can be used to recover the water for reuse and to dispose of the solid waste properly.

7. Stockpiling and Loading

Product storage: The final crushed and screened products are stockpiled in separate piles according to their size and grade. Stockpiles are usually located near the plant's loading area for easy access. Conveyor belts or front - end loaders are used to transfer the material from the production line to the stockpiles.

Loading for transport: When it's time to ship the products, they are loaded onto trucks, railcars, or barges for transportation to customers. The loading process needs to be carefully controlled to ensure accurate measurement of the quantity of material being shipped and to prevent spillage and damage during loading.

Each stage in the stone crusher plant plays a crucial role in processing the raw material and producing the final products. The efficiency and effectiveness of each stage contribute to the overall performance and quality of the end products.

Baichy Machinery has a history of more than 20 years. It not only produces a full set of crushing and sand making equipment, but also provides EPC project general contracting services, including plant site selection and construction, production line design and installation, and production and operation technical training. Welcome to consult online to get your exclusive stone crushing plant solution.

People Also Frequently Asked For - FAQ

1. What is the process of crusher?

Crushing is the process of transferring a force amplified by mechanical advantage through a material made of molecules that bond together more strongly, and resist deformation more, than those in the material being crushed do.

2. What are the three types of crushers?

The three primary types of crushers, categorized by their crushing action, are Jaw Crushers (compression), Cone Crushers (compression), and Impact Crushers (impact), with jaw crushers typically for primary crushing of large rocks, cones for secondary/fine crushing, and impact crushers for versatile use in breaking softer materials into fine products. Other key types include Gyratory Crushers, which are heavy-duty primary crushers, and Hammer Crushers, using striking hammers for crushing.

3. What are the other components of a crusher plant?

Other Components of a Crusher Plant

Vibrating Feeder: Feed raw materials into the crusher at a controlled rate.

Conveyor Belts: Transport crushed materials to different stages within the screening and crushing plant.

Screening Equipment: Separates crushed materials by size to ensure consistency.

4. How profitable is a stone crusher plant?

The stone crushing business is a lucrative sector within the construction and mining industries, offering steady demand as infrastructure development continues to grow worldwide. However, running a successful stone crushing business involves much more than just having the right equipment and materials.

2026-02-09

2026-02-09

86-15093113821

86-15093113821

86-15093113821

86-15093113821