If you are mining bauxite, you aren’t just fighting rock. The hardness, clay/water content and the required output particle size of bauxite are the three core bases for the selection of crushers. Bauxite with different characteristics have significant differences in the requirements for the abrasion resistance, clogging prevention and crushing efficiency of the crushing equipment. Deviation in selection will directly lead to low production capacity, rapid consumption of wear parts and a sharp increase in the cost per ton. The following are the targeted selection criteria, covering the entire process from coarse crushing to medium and fine crushing, taking into account both practicality and economy.

I. Clearly classify the core characteristics of bauxite

Bauxite is mainly divided into three types, which need to be confirmed through raw material testing first:

1. Gibbsite: Mohs hardness 5-6, high hardness, low clay content (usually <5%), the highest wear resistance requirement, and it is the core raw material for metallurgical grade bauxite;

2. Boehmite: Mohs hardness 2-3, soft, prone to clayification, clay content/water content often reaches 10%-30%, prone to clogging during crushing, mostly used in the chemical and building materials fields;

3. Mixed bauxite: hardness 3-5, clay content fluctuates greatly (5%-20%), needs to balance wear resistance and clogging prevention, and it is the most common raw material type.

II. Coarse Crushing Stage: Heavy Duty Jaw Crusher

The jaw crusher is suitable for all types of bauxite and is the standard equipment for coarse crushing of bauxite. It can handle large raw materials with a feed size of up to 800mm.

● Core Adaptability: The structure is robust and highly resistant to impact, making it less likely to get clogged by large or hard ores. The crushing ratio can reach 6:1 to 10:1, quickly reducing the raw ore to a size suitable for medium crushing (20 to 80mm). For coarse crushing, the appropriate model of jaw crusher can be directly selected based on production capacity.

III. Medium Crushing/ Fine Crushing Stage: Choose One Based on Characteristics

Medium crushing/fine crushing is a core decision point in equipment selection, which must strictly match the hardness and mud content of bauxite. The core lies in choosing between cone crushers and impact crushers, and a one-size-fits-all approach is not acceptable.

Option 1: Cone Crusher - The Preferred Choice for Hard Bauxite, High Mud Content, and High Output

Core Applicable Scenarios: Monohydrate bauxite, mixed bauxite; output over 50tph; production of metallurgical grade bauxite (with high requirements for uniformity of output particle size).

1. Core Matching Advantages:

- Utilizes the layer crushing principle, relying on the squeezing and grinding of materials against each other rather than direct impact by equipment components, significantly reducing wear on wear parts, with a lifespan 3 to 5 times that of impact crushers, and a 30% to 40% lower crushing cost per ton;

- The cavity structure is closed, with strong resistance to mudification. Even with a mud content of 10% to 20%, it is not prone to material blockage, making it suitable for mixed bauxite with fluctuating mud content;

- Stable operation with small output fluctuations, suitable for long-term and large-scale production.

2. Subdivision Selection:

- Single-cylinder cone crusher: Cost-effective option, suitable for processing mixed bauxite with a capacity of 50 to 150 tons per hour, and easy to maintain.

- Multi-cylinder cone crusher: High-efficiency option, suitable for processing high-hardness gibbsite bauxite with a capacity of 150 to 300 tons per hour, providing more uniform output particle size and longer wear part life.

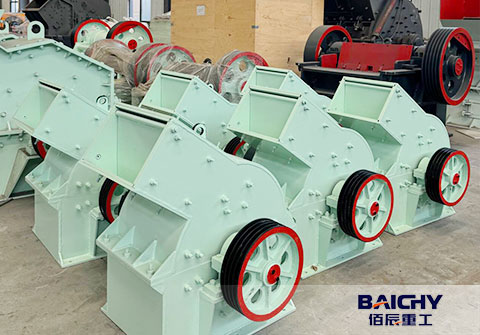

Option 2: Impact Crusher - Specifically designed for soft bauxite, low clay content, and cube-shaped particle requirements

Core application scenarios: Soft bauxite (bauxite from Sanshui); clay content < 5% (low clay content); production of construction-grade bauxite (with high requirements for cubic particle shape).

1. Core matching advantages:

- Impact crushing results in cubic-shaped output particles with low needle and flake content, meeting the particle shape requirements for construction and road aggregate;

- The equipment purchase cost is 30% to 50% lower than that of cone crushers, making it suitable for small-scale and short-term projects with a low entry threshold;

- High crushing efficiency, fast processing speed for soft bauxite, no need for high-power drive, and low energy consumption.

2. Key usage prerequisites:

- Absolutely prohibited for high-mud or wet materials: Bauxite is prone to mudification. When the mud content exceeds 5%, it will adhere to the hammer plates and impact plates, causing material blockage and production halt, and reducing the screening efficiency by more than 50%.

- Adequate spare parts must be prepared: The hammer plates are wear parts. Even when processing bauxite, they need to be replaced regularly, and reserves should be prepared in advance.

- Pre-treatment is required: If the mud content slightly exceeds the standard (5% to 10%), a pre-mud-removal screen should be installed to remove the mud before crushing.

IV. Installation and Support: We Build at Your Mine Site

We understand that bauxite mines are often located in remote tropical regions (Guinea, Indonesia, Brazil, Australia). Even the best machines are useless if they cannot be installed.

● Modular Steel Structure Stone Crusher Plant: Baichy provides prefabricated steel structure frames, reducing the need for large concrete foundations. This can shorten installation time by several weeks.

● Electrical Control (PLC): We offer integrated control panels to monitor motor loads. If the crusher is overloaded due to sticky materials, the system will automatically reduce the feeding speed to prevent blockages.

Baichy Machinery has a history of more than 20 years. It not only produces a full set of crushing and sand making equipment, but also provides EPC project general contracting services, including plant site selection and construction, production line design and installation, and production and operation technical training. Welcome to consult online to get your exclusive stone crushing plant solution. Send us your capacity requirements and raw material details. Our engineers will provide a full equipment list and ROI analysis within 24 hours.

People Also Frequently Asked For - FAQ

1. What is the process of crushing bauxite?

A bauxite crushing plant is a facility that crushes raw bauxite ore extracted from a mine into smaller pieces so that it can be conveyed and processed further. Crushing is usually a dry operation that takes place in two or three stages.

2.Why is bauxite crushed?

The most common initial process step to feed an alumina refinery with bauxite is the crushing or sizing of the raw bauxite material that is extracted from the mine. The feed material is crushed or sized so that it is conveyable, as well as correctly dimensioned, for the next step in the process.

3.Why is bauxite so valuable?

The bauxite is the primary source of aluminum to make cement that used for construction. Aluminum is used for transport carrier, consumer durables, packaging, electrical, machinery equipment, refractory bricks, and abrasives. Figure 1.33. Bauxite is a primary aluminum ore often with a pisolitic structure.

2026-02-07

2026-02-07

86-15093113821

86-15093113821

86-15093113821

86-15093113821