Cone crusher is the core equipment of a crushing plant. However, its harsh working environment - filled with abrasive dust and high-intensity impacts - often leads to unexpected shutdowns. Many users are facing common pain points: rapid deterioration of lubricating oil, uneven product particle size, and premature wear of cone crusher spare parts. To help you reduce operating costs and extend machine lifespan, we have compiled this comprehensive maintenance guide for cone crushers. As a trusted supplier of cone crushers, Baichi Machinery is committed to helping you maintain the optimal operation of your equipment.

Why Regular Cone Crusher Maintenance Matters

Neglecting cone crusher maintenance is a costly mistake. It doesn't just mean paying for repairs; it means lost production time. A cone crusher operates under extreme pressure. Without a strict maintenance schedule, minor issues like contaminated oil or worn liners can escalate into catastrophic failures, such as seized bushings or broken shafts.

● Effective maintenance ensures:

● Consistency: Stable discharge opening settings for uniform product size.

● Longevity: Extending the lifespan of expensive cone crusher spare parts.

● Cost Savings: Preventing major breakdowns before they happen.

Essential Maintenance Method 1: Lubrication System Management

The working condition of a cone crusher is notoriously poor. The air is often saturated with dust, which can easily infiltrate the system. If the lubricating oil becomes polluted, it leads to rapid deterioration of oil quality and damage to critical bearings.

Regular Replacement of Lubricating Oil

To ensure the smooth operation of your cone crusher, strict oil management is non-negotiable.

● Check Filters Monthly: Users must inspect and clean the supply oil filter, return oil filter, and the filter screen at least once a month. This prevents sludge and metal particles from circulating back into the crusher.

● Monitor Pressure: You need to check oil quality changes regularly. Ensure the working pressure is maintained between 0.08-0.15 MPa.

● Pressure Differentials: It is necessary to check the cone crusher pump supply pressure versus the pressure after the filter. Maintain a pressure difference between 0.02-0.04 MPa. A higher difference usually indicates a clogged filter.

● Oil Change Cycle: The typical usage period for the cone crusher oil pump and oil supply is around three months. While the oil in the hydraulic station can be reused, it must be filtered thoroughly before being put back into the system.

Essential Maintenance Method 2: Discharge Opening Adjustment

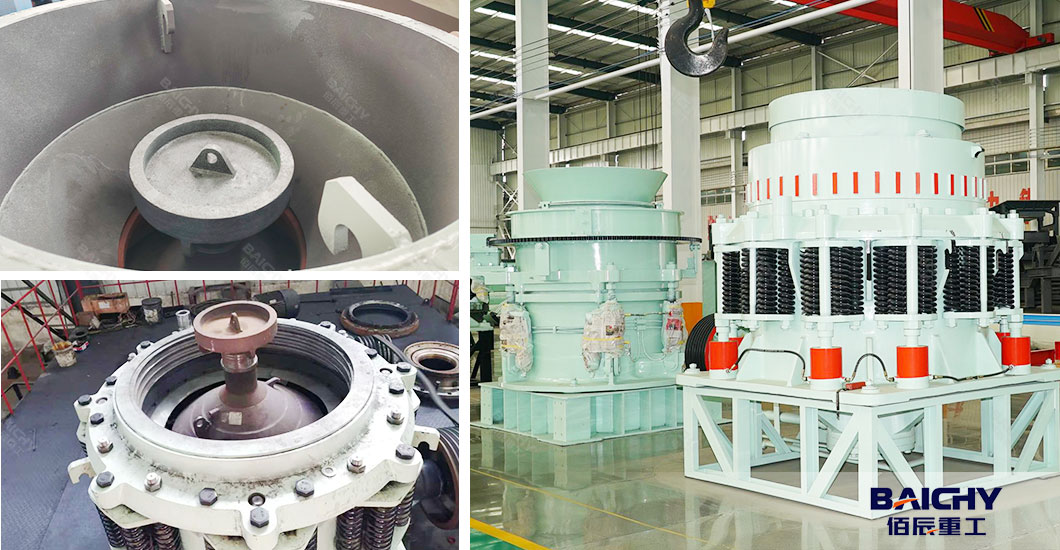

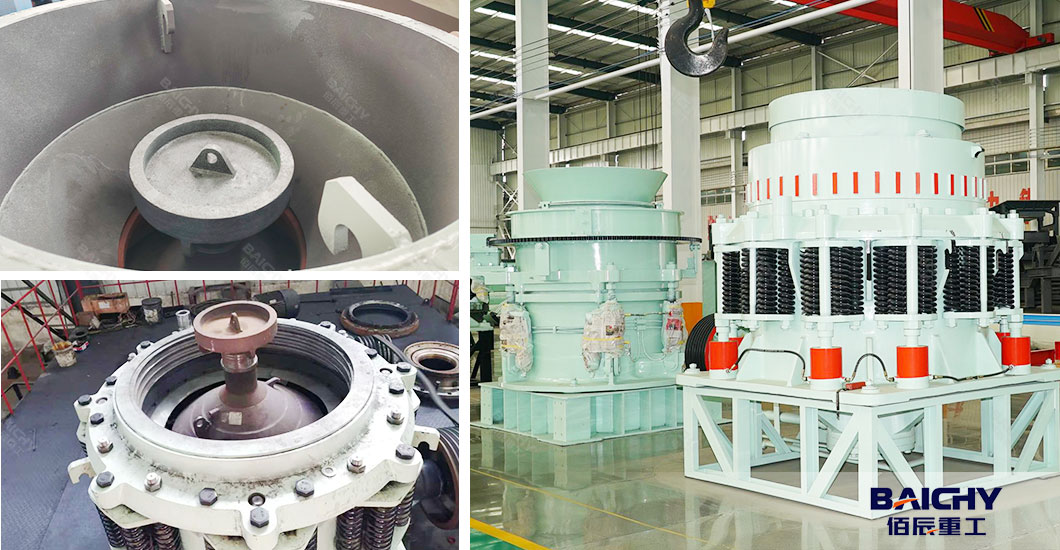

In the crushing process, the cone crusher spare parts—specifically the movable cone liner (mantle) and the fixed cone liner (concave)—are subjected to continuous wear. As these parts wear down, the size of the discharge opening (CSS) gradually increases.

If left unadjusted, the product granularity will become coarser, failing to meet production requirements. Therefore, regular cone crusher maintenance involves adjusting the discharge opening to compensate for liner wear.

How to Adjust the Discharge Opening Safely

Modern cone crusher designs allow for hydraulic adjustment, but the procedure must be followed strictly to avoid damaging the machine.

● Unlock the System: First, open the lock cylinder pressure relief valve. This relieves the pressure in the lock cylinder, allowing the adjustment ring to move.

● Hydraulic Adjustment: Use the hydraulic push cylinder (or serrated thread lifting mechanism) to rotate the adjustment ring.

● To decrease the opening: Promote the adjustment ring to lift the fixed cone liner.

● To increase the opening: Drop the fixed cone liner.

● Lock and Secure: After finishing the adjustment to get the desired cone crusher discharge size, you must tightly lock the adjustment ring with the lock cylinder.

● Warning: It is strictly forbidden to boot the machine if the adjustment ring is not locked. Doing so can destroy the threads and the supporting suite.

Inspecting Cone Crusher Spare Parts to Avoid Downtime

A reliable cone crusher supplier will always advise you to keep an eye on your wear parts. Waiting until a part fails completely is a recipe for disaster.

● Liners: Check the mantle and concave for uneven wear. If they are worn too thin, the cone crusher performance drops, and the main frame risks damage.

● Seals: Dust is the enemy. Regularly check dust seals to ensure no abrasive materials are entering the lubrication system.

● Spare Parts Strategy: Keep essential cone crusher spare parts in stock. Having a spare set of liners and filters can reduce a potential week-long shutdown to just a few hours.

Choosing the Right Cone Crusher Supplier

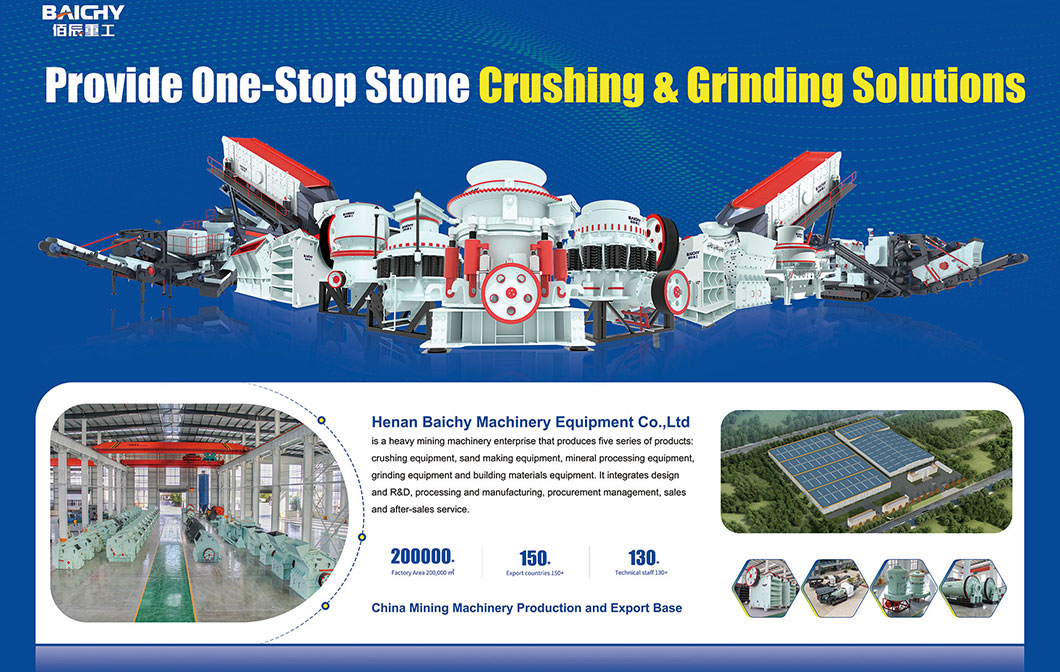

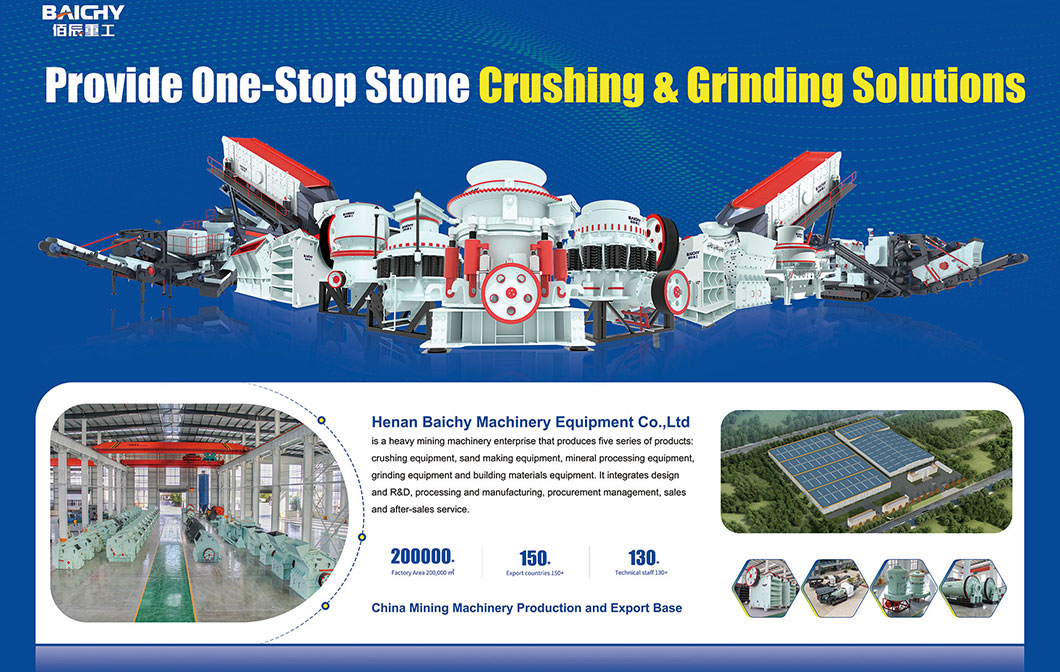

Not all crushers are created equal. As we all know, different types of cone crushers (Spring, Symons, Hydraulic) have different characteristics and maintenance requirements.

When selecting a cone crusher supplier, look for one that offers:

● Technical Support: Engineers who can guide you on flexible maintenance ways suitable for your specific site conditions.

● Quality Parts: High-quality cone crusher spare parts that last longer and fit perfectly.

● Comprehensive Manuals: Clear instructions on pressure settings and adjustment procedures.

Contact Baichy Machinery Today for a free consultation, a detailed maintenance manual, or a quote on high-quality cone crusher spare parts.

People Also Frequently Asked For - FAQ

1. How do you maintain a cone crusher?

Users must check and clean supply oil filter, return oil filter and the filter screen monthly, also need to check the oil quality changes, make the working pressure maintains between 0.08-0.15MPa.

2. What is the schedule of crusher maintenance?

Preventive maintenance is usually set up on a daily (8 hours), weekly (40 hours), monthly (200 hours), yearly (2,000 hours), and liner change schedule. Following the scheduled checks and inspections, adjustments are made and worn parts are replaced before a major crusher breakdown occurs.

3. How can I increase my crusher production?

A larger feed size and a finer gradation can increase the capacity, but it may also increase the wear on the crusher. It is important to find the right balance between these factors. Proper maintenance: Proper maintenance of the crusher can help to increase its production capacity.

2026-02-10

2026-02-10

86-15093113821

86-15093113821

86-15093113821

86-15093113821