A 50 tons per hour (TPH) stone crusher plant is a versatile choice for medium-scale aggregate production, catering to construction, road building, and mining needs. Whether you opt for a fixed setup or a mobile unit, this capacity balances productivity and flexibility. Let’s compare fixed and mobile 50TPH stone crusher plants to help you choose the right fit.

What is a 50TPH Stone Crusher Plant?

A

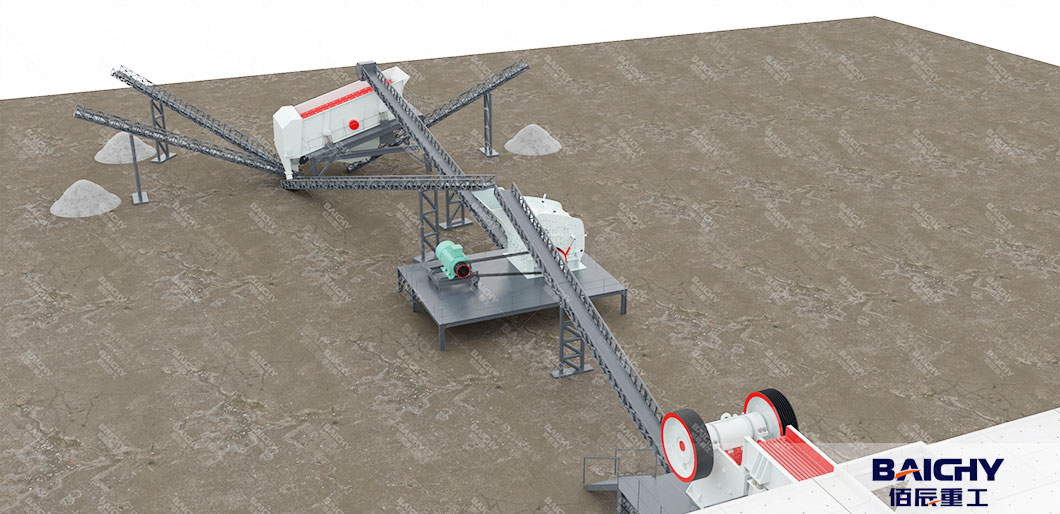

50TPH stone crusher plant processes 50 tons of raw stone (limestone, granite, basalt, etc.) per hour, producing graded aggregates (5–50mm) for various applications. It combines crushing, screening, and conveying equipment to transform large stones into usable materials. The key distinction lies in mobility: fixed plants are stationary, while mobile plants can be transported to job sites.

Fixed 50TPH Stone Crusher Plant: Stability for Long-Term Operations

Ideal For:

● Quarries with consistent stone sources.

● Permanent construction hubs (e.g., concrete batching plants).

● Projects requiring long-term, high-volume production in one location.

Equipment Configuration:

● Feeding System: Vibrating feeder (e.g., GZD 850×3000) with grizzly bars to remove fines and control material flow.

● Primary Crushing:

Jaw crusher (e.g., PE 500×750) reduces stones from 300mm to 50–80mm.

● Secondary Crushing: Cone crusher (e.g., CS 400) or impact crusher (e.g., PF 1214) refines material to 5–50mm.

● Screening: 3-deck vibrating screen (e.g., 3YK 1548) separates aggregates into grades (0–5mm, 5–10mm, 10–20mm).

● Conveyors & Storage: Belt conveyors (650mm width) transport material between stages; stockpiles store finished products.

● Dust Control: Pulse bag filter and water sprays to meet environmental standards.

Advantages:

● Higher Efficiency: Optimized layout reduces energy loss, lowering per-ton production costs.

● Durability: Heavy-duty components withstand continuous operation, ideal for hard stones like granite.

● Scalability: Easy to expand with additional crushers or screens as demand grows.

Mobile 50TPH Stone Crusher Plant: Flexibility for On-Site Crushing

Ideal For:

● Demolition sites (recycling concrete rubble).

● Road construction projects (crushing local stone for road bases).

● Remote locations with scattered stone sources.

Equipment Configuration:

● A

mobile stone plant 50tph integrates all components on a tracked or wheeled chassis:

● Integrated Feeder & Crusher: Jaw crusher PE400X600 with a built-in vibrating feeder, handling 300mm stones.

● Screening Unit: Foldable vibrating screen (e.g., 2YK 1236) mounted on the same chassis or a separate mobile screen.

● Conveyors: Hydraulically foldable belts for quick setup (no need for separate installation).

● Power Source: Diesel generator (for off-grid sites) or electric motor (for connected areas).

Advantages:

● Mobility: Tracked models navigate rough terrain; wheeled units move easily on roads, reducing transportation costs for raw materials.

● Quick Setup: Ready to operate in 30–60 minutes, minimizing downtime between job sites.

● Versatility: Crushes various materials (stone, concrete, asphalt) without reconfiguring the plant.

How to Choose Between Fixed and Mobile?

● Location: Choose fixed if you have a permanent site with steady stone supply; mobile if you need to move between projects.

● Material Type: Fixed plants excel with hard, abrasive stones; mobile plants handle mixed materials (e.g., demolition waste) efficiently.

● Cost: Fixed plants have higher upfront costs but lower long-term operational expenses; mobile plants cost more initially but save on transportation.

Applications of 50TPH Stone Crusher Plants

● Construction: Produces aggregates for concrete, bricks, and building foundations.

● Road Building: Supplies 10–30mm stones for road bases and 5–10mm fines for asphalt.

● Mining: Crushes ore into manageable sizes for further processing.

A 50TPH stone crusher plant—whether fixed or mobile—delivers the right balance of capacity and practicality for medium-scale operations. Fixed plants thrive in permanent settings, while mobile units shine in dynamic, on-site crushing scenarios. Evaluate your project’s location, material, and long-term goals to make the best choice. Henan Baichy Machinery Equipment Co., Ltd. is a mining machinery manufacturer integrating R&D, production and sales. Stone crusher is one of its core production equipment. It has mature technology and processes, complete models and configurations, and technical engineers can tailor production line configuration plans for you. If you are interested in the stone crusher, please click on the online consultation to

get solution and price now. Baichy Machinery is dedicated to serving you 24 hours a day!

People also frequently asked for-FAQ

1.What is the capacity of stone crusher plant?

Baichy provide various stone crusher plant with capacity 50tph, 80tph, 100tph, 150tph, 200tph, 250tph, 300tph, 500tph. All those are standard crushing plant to meet requirement.

2.What are the different types of stone crusher plants?

However, you'll find four basic designs—cone, jaw, gyratory, and impact crushers—operating within many crushing plants. Different configuration, the efficiency and cost will be different.

3.How do you set up a stone crusher plant?

The stone crusher plant consists of a crushing setup of excavators, feeders, primary and secondary crushers and screeners. They all work together to crush stone as efficiently as possible. To set up a successful stone crusher plant means balancing plant design, cost and efficiency. But first, you’ll need to learn how to optimize your crushing setup while choosing the best machinery for your crushing needs.

2026-02-06

2026-02-06

86-15093113821

86-15093113821

86-15093113821

86-15093113821