Iron ore—whether magnetite, hematite, or limonite—requires robust crushing equipment to handle its high hardness (compressive strength up to 300+ MPa) and varying feed sizes (0–1000mm). Mobile crushers eliminate the limitations of fixed plants, enabling on-site processing and cost-saving mobility. If you are looking to optimize your iron ore beneficiation process, understanding the right equipment is crucial. Here is a breakdown of the best mobile crushers for iron ore, their advantages, and a real-world success story from the mining heartland of Australia.

1. Suitable Types of Mobile Crushers for Iron Ore

Iron ore is a hard, abrasive, and dense material. Therefore, mobile crushers used for primary and secondary crushing must be exceptionally robust. The two main types suitable for iron ore applications are:

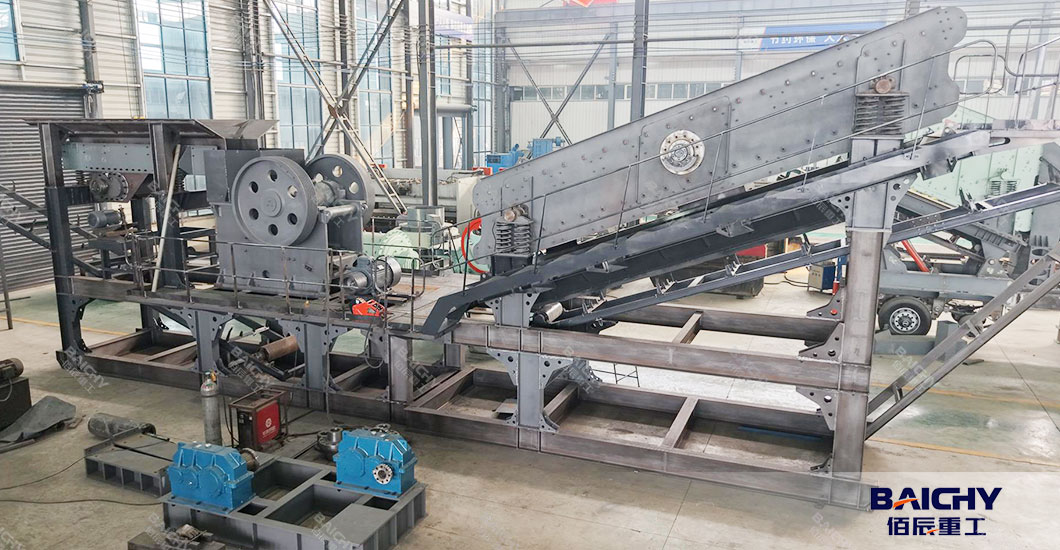

● Mobile Jaw Crushers (Primary Crushing): These are the workhorses for the first crushing stage. They are designed to handle large feed sizes directly from the mining face, breaking down massive ore chunks into manageable sizes (typically down to 150-200mm). Their simple, sturdy design and strong crushing force make them ideal for the high compression strength of iron ore.

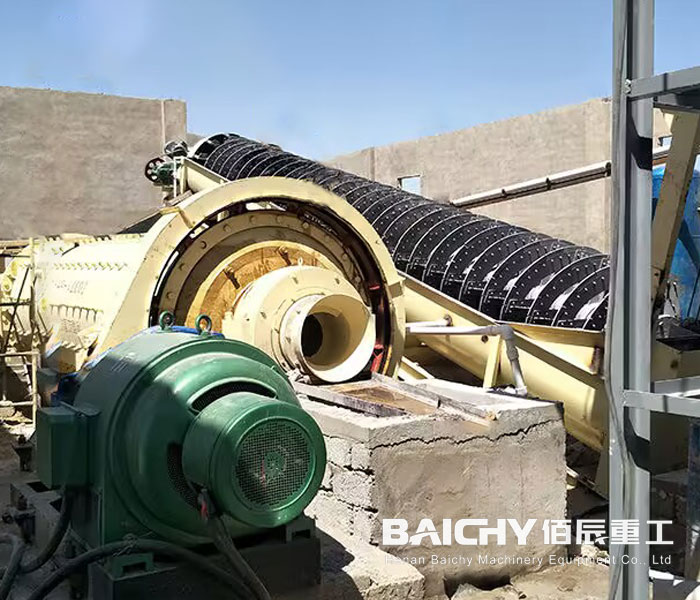

● Mobile Cone Crushers (Secondary/Tertiary Crushing): For producing precisely graded, finer products required for beneficiation or direct shipping, mobile cone crushers are essential. Following the jaw crusher, they further reduce the ore size through a compression process between a rotating mantle and a fixed concave. They excel at producing cubicle end products and are highly efficient in closed-circuit operations with a screening unit.

2. Advantages & Characteristics of Each Mobile Crusher

● Mobile Jaw Crusher Advantages:

○ High Capacity & Robustness: Built with heavy-duty components to withstand continuous feeding of hard, abrasive iron ore.

○ Direct Feed from Face: Eliminates the need for a primary stationary crusher and reduces reliance on large mining trucks for primary haulage.

○ Fuel Efficiency (Direct Drive Models): Modern units often feature direct drive systems, translating engine power more efficiently into crushing force, reducing fuel consumption—a major operational cost.

○ Fast Relocation: Hydraulic walking mechanisms or easy trailer transport allow the entire unit to move within or between pits in a matter of hours.

● Mobile Cone Crusher Advantages:

○ Precise Product Shaping: Produces more uniform, cubicle particles compared to impact crushers, which is often crucial for downstream processing like pelletizing or sintering.

○ High Reduction Ratio & Efficiency: Capable of achieving significant size reduction in a single machine, making the crushing circuit more compact.

○ Closed-Circuit Flexibility: When integrated with a mobile screen on the same chassis (closed-circuit design), it allows for immediate recirculation of oversized material, optimizing final product specification.

○ Automation & Setting Adjustments: Advanced models feature automatic setting regulation (ASRi systems) to maintain optimal performance and protect the crusher from tramp metal or uncrushables.

3. Success Case: Track-Mounted Jaw Crusher in Australia

Australia's Pilbara region is home to some of the world's largest iron ore mines, where operational efficiency dictates profitability. A leading mining contractor faced a challenge at a satellite deposit: the distance from the main processing plant was increasing haulage costs, and establishing a new stationary crushing line was not feasible for the deposit's 3-year life.

● The Solution: The contractor deployed a high-capacity track-mounted mobile jaw crusher, specifically chosen for its robustness and autonomy.

● Implementation & Results:

○ On-Face Crushing: The track-mounted jaw crusher was positioned directly at the mining face. Large haul trucks dumped ROM (Run-of-Mine) iron ore directly into its large-capacity feeder.

○ Primary Crushing On-Site: The crusher reduced the ore from ~1,000mm to a conveyable size of 0-250mm.

○ Integrated Conveying: A mobile conveyor belt system transported the crushed ore directly to a train loading yard, bypassing the need for dozens of truck cycles.

● Key Outcomes:

~40% Reduction in Haulage Costs: By crushing at the face, the haul distance for the larger, heavier trucks was drastically cut.

Rapid Deployment: The plant was operational within days of arrival on site.

Exceptional Availability: The crusher's heavy-duty build and easy maintenance access resulted in over 95% operational availability in the harsh desert environment.

Flexibility: As the mining face advanced, the entire crushing setup could be relocated in under 24 hours, keeping the operation optimally positioned.

For iron ore mining, mobile crushers—particularly track-mounted jaw crushers for primary duty and cone crushers for fine crushing—offer an unbeatable combination of flexibility, cost reduction, and efficiency. For mines dealing with multiple pits, satellite deposits, or requiring flexible production schedules, investing in a mobile iron ore crushing solution is a strategic move toward greater profitability and operational agility. Welcome to contact Reliable Baichy Machinery to get profesional solution and price list.

People Also Frequently Asked For - FAQ

1. Which type of mobile crusher is best for iron ore?

A: Because iron ore is typically very hard and abrasive, the best configuration is a Mobile Jaw Crusher for primary crushing followed by a Mobile Cone Crusher for secondary crushing. We generally advise against using Impact Crushers for iron ore, as the abrasive material causes excessive wear on the blow bars, leading to high operating costs.

2. How is the mobile crusher powered in remote mining sites?

A: Most modern mobile crushers are equipped with a Dual Power system. This means they have an onboard diesel generator to operate independently in off-grid remote areas, but can also switch to external electric power where available to reduce fuel costs.

3. Is the machine durable enough for high-hardness iron ore?

A: Yes. Mobile crushers designed for mining are built with heavy-duty chassis and equipped with premium wear parts (such as high-manganese steel jaw plates and mantle/concave liners). This specific design ensures they can withstand the high pressure and abrasiveness of processing iron ore without frequent breakdowns.

2026-01-31

2026-01-31

86-15093113821

86-15093113821

86-15093113821

86-15093113821