South Africa is rich in mineral resources, but the most challenging materials for local quarries and construction contractors are dolerite and silica. Dolerite is hard and highly abrasive, while silica causes extreme wear on wear parts, making ordinary hammer crushers or impact crushers unsuitable (due to extremely high wear costs). Considering the characteristics of South African ores, the following five classic crusher types, their features, and prices are recommended:

Main Machines For Hard Stones in South Africa

1. Jaw Crusher (PE Jaw Crusher) - "Pioneer in Coarse Crushing"

● Application Scenarios: Jaw crusher is widely used in primary processing in all stone crushing production lines. It could crush 100mm-800mm large stones to medium particle size.

● Advantages for South Africa: It has a large crushing ratio and is specially designed for large pieces of coarse rocks. Uses high-manganese steel (Mn13Cr2) jaw plates, offering high wear resistance, simple structure, and extremely low maintenance costs.

● Price range: $5,000 - $85,000 USD (depending on model PE-250×400 to PE-900×1200).

2. Symons Cone Crusher

● Application: Symons cone crusher is often used as secondary crushing process. Suitable for medium-sized quarries.

● Advantages in South Africa: Mature technology, readily available spare parts in South Africa, cheaper than hydraulic cone crushers, suitable for start-up projects with limited budgets.

● Price range (FOB China): $30,000 - $125,000 USD.

3. Single Cylinder Hydraulic Cone Crusher

● Application: CH seires single cylinder hydrarlic cone crusher is used in large mines requiring extremely high throughput.

● Advantages for South Africa: High level of intelligence; automatic clearing function allows for rapid recovery from iron blocks or jamming, reducing downtime.

● Price Range (FOB China): $50,000 - $180,000 USD.

4. Multi-Cylinder Hydraulic Cone Crusher - "Hard Rock Buster"

● Application Scenarios: HPC series cone crusher is specifically designed for large-scale mining, high-speed rail, airport infrastructure, and large-scale processing of aggregates production plant.

● Advantages for South Africa: Utilizes the "layered crushing" principle, offering high crushing efficiency for high-hardness rocks and producing excellent culet shape, fully meeting South African SABS construction standards. A must-have if your customers have high requirements for stone shape.

● Price Range (FOB China): $60,000 - $220,000 USD.

5. Tracked Mobile Crusher - "Power Outage Resistant"

● Application Scenarios: Track mounted mobile stone crusher is widely used for mining areas with complex terrain or short-term projects. Or remote mining areas and temporary projects are particularly suitable for the decentralized mining layout in South Africa.

● Load Shedding: Equipped with a high-powered diesel engine, completely independent of the Eskom power grid, enabling 24/7 uninterrupted production.

● High Mobility: Remotely operated, strong climbing ability, no need for concrete foundations.

● Price Range (FOB China): $150,000 - $450,000+ USD.

Stone Crusher Equipment : New vs. Used

In South Africa, the second-hand market (on sites like Gumtree or Bidorbuy) is active, but buying used crushers for hard rock is risky.

| Feature |

New Equipment |

Used Equipment |

| Initial Price |

Higher (Includes Shipping) |

Lower (Seems cheap upfront) |

| Suitability |

Customized for Hard Rock |

Unknown config (Often used for soft limestone) |

| Hidden Costs |

Low (Under Warranty) |

Sky High (Hydraulic leaks, expensive repairs) |

| Lifespan |

10-15 Years |

Unpredictable (Near end-of-life) |

| Spare Parts |

Guaranteed Factory Supply |

No Support (Hard to find parts) |

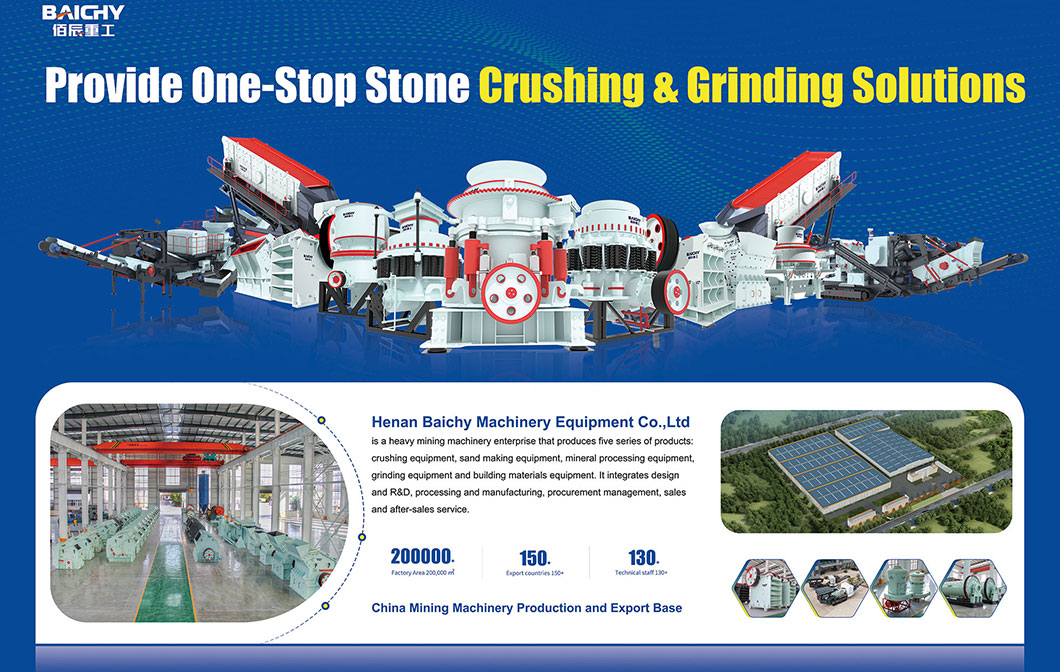

Henan Baichy Machinery Equipment Co.,Ltd is a heavy mining machinery manufacturer that produces five series of products: crushing equipment, sand making equipment, mineral processing equipment, grinding equipment and building materials equipment. It integrates design and R&D, processing and manufacturing, procurement management, sales and after-sales service. The products have been exported to over 150 countries and widely used in global mining and construction industry.

Baichy’s stone crusher equipment offers:

● Tailored configurations for hard/medium-soft ores.

● Rapid deployment and easy transfer between sites.

● Low total cost of ownership (TCO) with energy-efficient operation and durable parts.

● Compliance with global environmental and safety standards.

Top 3 FAQs from South African Clients

Q1: With frequent Load Shedding (Eskom issues), how can your machines work?

A: We fully understand the power instability in South Africa.

For Stationary Plants, we provide matching Diesel Generator Sets (Gensets) to ensure 24/7 operation.

For Mobile Plants, we highly recommend our Tracked or Wheeled Mobile Stations. They have onboard diesel engines and are 100% independent of the Eskom grid.

Q2: How do you get the machine to my mine? Is shipping expensive?

A: Baichy Machinery has extensive experience exporting to SA. We can ship the equipment via CIF terms directly to Durban Port or Cape Town Port. We calculate the most economical container loading plan (e.g., disassembly for shipping) to minimize sea freight costs.

Q3: Dolerite is extremely hard. What if the wear parts wear out too fast?

A: Specifically for the South African market, we provide "Reinforced" Wear Parts. Our Jaw Plates and Mantles use modified High Manganese Steel (Mn18Cr2) and High Chrome alloys, which last 30%-50% longer than standard parts.

Pro Tip: We recommend buying a "1-Year Spare Parts Package" inside the container with your machine. This saves you huge money on future air freight.

2026-02-13

2026-02-13

86-15093113821

86-15093113821

86-15093113821

86-15093113821