In a stone crusher plant, the vibrating screen is more than just a “classifier”—it directly impacts aggregate quality, production efficiency, and even the lifespan of downstream equipment. A mismatched vibrating screen can cause bottlenecks (e.g., undersized aggregates clogging conveyors) or waste (e.g., oversized material re-entering crushers unnecessarily). Whether you’re processing granite, limestone, or basalt, choosing the right vibrating screen requires focusing on material traits, 产能 (capacity), and plant needs. This guide breaks down 6 key steps to select a vibrating screen that fits your stone crushing workflow.

1. Analyze Your Material’s Characteristics

The stone you process determines the screen’s design. Ignore this, and you’ll face frequent clogging or wear:

● Hardness: For abrasive stones (granite, basalt, Mohs 6–8), choose screens with wear-resistant materials (manganese steel, high-chromium alloy). Soft stones (limestone, gypsum, Mohs 3–5) work with carbon steel or polyurethane screens (cheaper and lighter).

● Moisture Content: Wet, sticky stones (e.g., clay-covered limestone) need anti-clog screens—opt for polyurethane mesh (with larger open areas) or vibrating screens with “self-cleaning” features (e.g., bouncing balls under the screen to shake off stuck material). Dry stones (e.g., quartz) can use standard steel mesh.

● Feed Particle Size: If your crusher outputs 50–150mm stone, pick a screen with a “grizzly” upper layer (large gaps) to remove oversized lumps first. For fine crushing (5–20mm aggregates), use a fine-mesh screen (10–20mm openings) with high vibration frequency.

2. Match Screen Capacity to Your Stone Crushing Line

● Calculate needs: If your jaw crusher produces 100 TPH of 80–150mm stone, choose a vibrating screen with 120–150 TPH capacity (add 20–50% buffer to handle peak loads).

● Avoid overcapacity: A 200 TPH screen for a 50 TPH crusher wastes energy and space. Conversely, a 50 TPH screen for a 100 TPH crusher will pile up material, forcing the crusher to slow down.

● Example: A limestone crusher plant in India uses a 100 TPH jaw crusher paired with a 120 TPH 3YK 1860 vibrating screen—no bottlenecks, even during 12-hour shifts.

3. Select Screen Layers Based on Output Aggregate Grades

Vibrating screens come with 1–4 layers (decks), each with different mesh sizes. Choose layers based on how many aggregate grades you need:

● 1 layer: For single-grade output (e.g., 20–30mm road base). Ideal for small plants focused on one product.

● 2 layers: For two grades (e.g., 10–20mm concrete aggregates + 20–30mm road base). The most common choice for medium plants.

● 3–4 layers: For multiple grades (e.g., 5–10mm, 10–20mm, 20–30mm, 30–50mm). Suits large plants supplying diverse construction projects (high-rises, highways).

● Tip: More layers mean higher precision but require a wider screen (e.g., 1800mm width for 3 layers) to maintain capacity.

4. Prioritize Durability for Long-Term Use

Stone crusher plants run 8–16 hours daily—your vibrating screen must withstand constant vibration and stone impact:

● Frame: Choose a screen with a heavy-duty steel frame (thickness ≥8mm) and reinforced welds. Avoid thin frames (≤5mm) that bend under vibration.

● Screen Mesh: Replaceable mesh is a must. For hard stones, use manganese steel mesh (lasts 3–6 months); for soft stones, polyurethane mesh (lighter, quieter, lasts 4–8 months).

● Vibration Motor: Pick a branded motor (e.g., ABB, Siemens) with IP54/IP65 protection (dustproof, waterproof). Cheaper motors fail within 6–12 months in dusty plant environments.

5. Consider Installation & Space Constraints

Your plant’s layout dictates the screen’s size and type:

● Space: If your plant is compact, choose a “horizontal vibrating screen” (low height, fits under conveyors). For outdoor quarries with more space, a “inclined vibrating screen” (15–25° angle, higher capacity) works better.

● Installation: Look for screens with easy mounting (flange connections) to existing conveyors. Avoid custom installations that take weeks—standardized models cut setup time to 1–2 days.

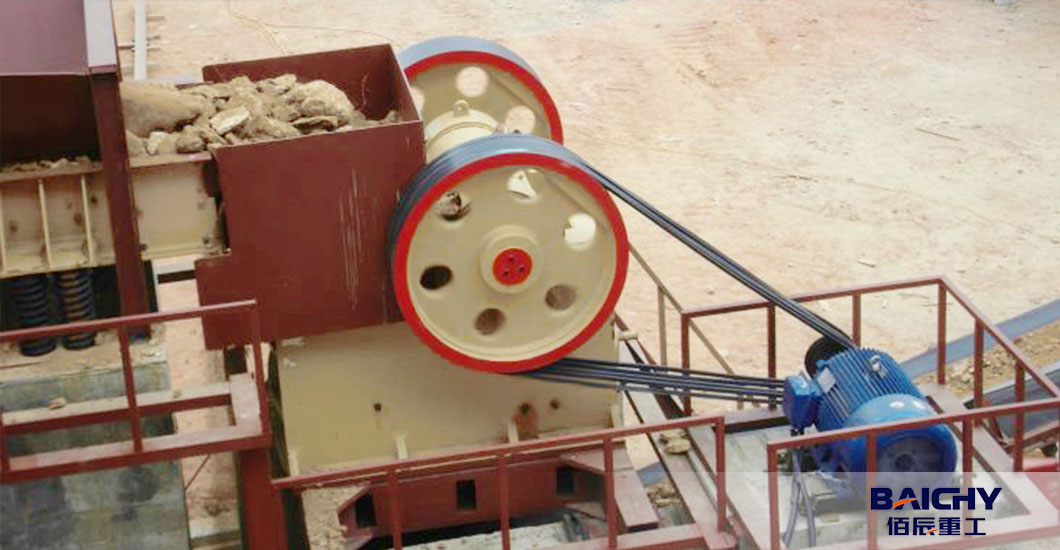

Real Case: circular vibrating screen in 200tph stone crushing plant

Here is a real case about stone crushing plant 200tph in Indonesia. It is configured with hopper, vibrating feeder ZSW1149, primary jaw crusher PE-750*1060, cone crusher CS220, vibrating screen 2YK2460, VSI sand making machine VSI 1145, 3-layer vibrating screen 3YK2460 and belt conveyors.

Process of 200tph stone crusher plant

1. The truck unloads the stones into the hopper, the stone enters the vibrating feeder from the lower part of the hopper;

2. The vibrating feeder feeds the stones evenly to the primary jaw crusher;

3. The crushed output materials from the primary jaw crusher will be transported to the secondary cone crusher by a belt conveyor;

4. The crushed output materials from the secondary cone crusher will be transported to the two-layer vibrating screen 2YK2460;

5. After screening by the two-layer vibrating screen, we will get 0-5mm, 5-35mm, +35mm materials. The 0-5mm materials will be transported out by a belt conveyor to stockpile, 5-35mm materials will be transported to VSI Crusher, +35 materials will be back to cone crusher for re-crushing.

6. 5-35mm materials will be crushed and shaped by VSI crusher, the output materials will be transported to the second vibrating screen 3YK2460.

7. After the screening, we will get 0-5mm, 5-15mm, 15-31.5mm materials, the +31.5mm materials will be transported back to VSI crusher. The role of VSI crusher in this setup for producing high standard output materials for mixing stations, asphalt stations, etc.

During this crushing plant, vibrating screen plays an important role to get high quality aggregates and sand. Due to the stable structure and powerful vibration, it could work in a hig efficiency speed to screen and classify the material perfectly.

Conlusion

Choosing the right vibrating screen isn’t about picking the “most expensive” option—it’s about matching it to your material, capacity, and plant goals. A well-selected screen will boost aggregate quality, reduce downtime, and lower long-term costs.

Not sure which screen fits your stone crusher plant? Share your material type (granite/limestone), capacity needs, and desired aggregate grades—we’ll recommend a

customized vibrating screen solution, with local spare parts and installation support.

People Also Asked Frequently - FAQ:

1. What is a vibrating screen used for?

A vibrating screen separates materials by size and can be used to improve and solve many product handling challenges. Typical applications include: Removing oversize material from usable product.

2. What are the disadvantages of a vibrating screen?

In daily production, vibration screen will encounter a variety of problems, such as poor screening quality, bearing overheating, abnormal sound, wrong technical indicators and so on. Baichy could help you to solve the vibrating screen problems.

3. How do you maintain a vibrating screen?

Clean the machine completely, paying close attention to any areas where material may cake or build up. Inspect the mounting system. Ensure it is secure and free from damage, paying close attention to cracks or other damage that could transform into a costly breakdown over time.

2026-01-15

2026-01-15

86-15093113821

86-15093113821

86-15093113821

86-15093113821